Performance Advantages of Negative Temperature Air Conditioning Chamber

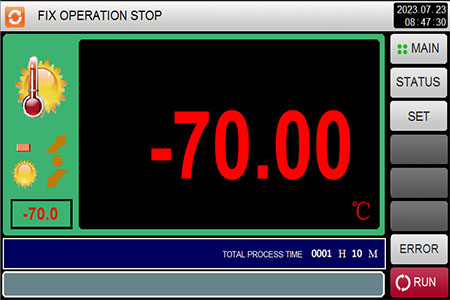

1. True Negative Temperature Conditioning

Temperature range: –70 °C to +150 °C (configurable)

Stability: ±0.5 °C, uniformity: ≤ ±2.0 °C

Optimized for steady-state sub-zero holding and conditioning accuracy, ensuring thermal equilibrium across long test durations rather than transient cooling performance

2. Air-Conditioning-Oriented Airflow Engineering

High-efficiency centrifugal circulation system with variable airflow control

Engineered air duct geometry for full-volume coverage

Ensures consistent cold-air distribution, reducing specimen-to-specimen temperature deviation in multi-sample testing

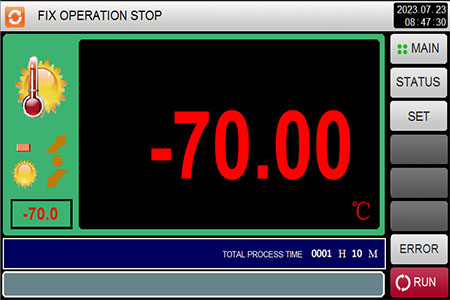

3. Intelligent Temperature Control & Data Integrity

Advanced PID control with adaptive self-tuning

Programmable multi-step temperature profiles and cyclic logic

Continuous data logging ensures traceable, repeatable, and audit-ready test results aligned with IEC and ISO test protocols

4. Operational Reliability & Service Life

Designed for 24/7 laboratory and production environments

Key components validated under extended low-temperature endurance testing

Modular design simplifies maintenance and minimizes downtime over the equipment lifecycle

Negative Temperature Air Conditioning Chamber Specifications

Model | T-100 | T-225 | T-500 | T-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

Cooling system | Mechanical compression refrigeration system.Environmentally friendly refrigerant,compliant with the GWP standards requirements |

Refrigerating unit | French TECUMSEH compressor |

Heating Element | Nichrome heater |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water supply system | Automatic water supply, Water purification system |

Safety Device | Over-temperature protection; Over-current protection; Refrigerant high-pressure protection; Earth leakage protection |

Structural & Functional Details of Negative Temperature Air Conditioning Chamber

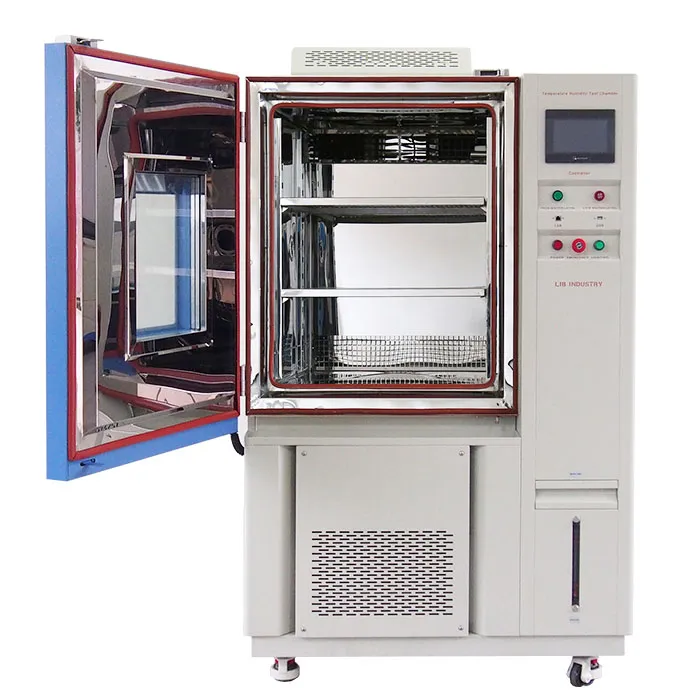

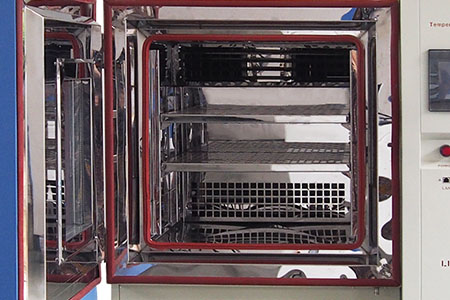

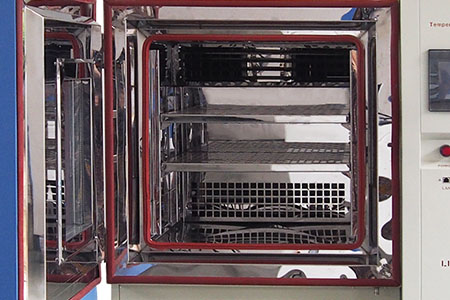

Reinforced Test Workspace | Interior material: SUS304 stainless steel Standard volumes: 100 L | 225 L | 500 L | 800 L | 1000 L Load-bearing specimen 2 layer shelves for heavy or dense samples Large-area heated observation window, effectively preventing frosting and condensation during deep negative temperature testing

|

|

Precision Control Platform

| Programmable touch controller with PID self-tuning Multi-step temperature profiles and cyclic programs(120 programs 99+ steps) USB / Ethernet communication for data export and system integration PC/mobile connections for remote control

|  |

Thermal Insulation & Sealing System | High-density 100 mm polyurethane insulation structure Low-temperature-resistant silicone sealing, Effectively suppresses cold loss and frost formation Embossed and recessed inner chamber design, reducing internal thermal radiation reflection

|  |

Refrigeration System & Temperature Sensing | Cascade refrigeration system supports stable operation down to –70 °C, designed for long-duration negative temperature conditioning,responsive cooling and steady temperature holding PT100 platinum resistance temperature sensors (Class A, IEC 60751) monitor real-time temperature High-resolution signal processing enables control resolution up to 0.001 °C

|  |

Built Around Your Test Method, Not a Fixed Model

LIB industry treats negative temperature chambers as engineering projects, not fixed models.

Custom options include:

Non-standard chamber dimensions and door structures

Enhanced cooling rate or ultra-low temperature holding optimization

Multiple cable ports, access holes, or viewing windows

Special airflow direction for application-specific conditioning

Remote monitoring, MES integration, and data management solutions

Discover More About Negative Temperature Air Conditioning Chamber

Q1: Can it maintain –70 °C for extended periods?

Yes. The refrigeration system and insulation structure are specifically designed for long-duration deep cold operation, not intermittent testing.

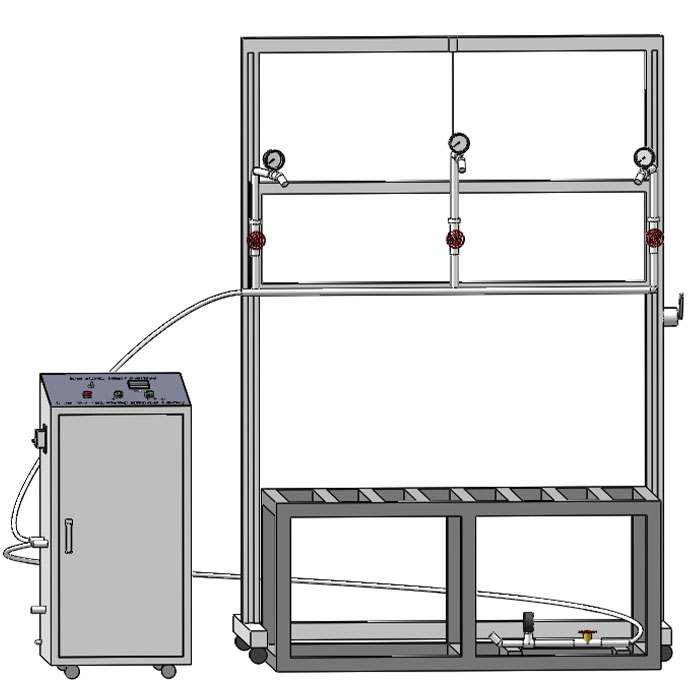

Q2: What other environmental test systems does LIB industry provide?

LIB industry offers a full environmental test portfolio including temperature humidity chambers, thermal shock chambers, xenon and UV aging systems, sand and dust chambers, and IP waterproof test equipment, enabling complete lab construction.

Q3: How flexible is LIB industry in customization?

From mechanical structure to control logic and performance tuning, LIB industry customizes around your test method, standards, and workflow.

Ready for Reliable Sub-Zero Testing?

If your testing requires stable, repeatable, and application-oriented negative temperature air conditioning, choose a system engineered beyond standard cooling logic.

LIB industry delivers custom-built solutions, fast technical response, and lifecycle-level support.

3-Year Warranty | Engineered-to-Order | Lifetime Technical Support

Contact LIB industry now inquiry@libtestchamber.com to receive a quotation and tailored test proposal within 1–3 hours.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia