For the testing of micro-components, it is necessary to have the dual characteristics of high performance and small size. The benchtop environmental chamber is specifically designed to meet such testing requirements and has been widely applied in multiple fields such as electronics, automobiles, aerospace, and medical care.

The benchtop environmental chamber is a desktop environmental simulation device, mainly used for conducting environmental stress tests such as temperature and humidity on small-sized samples.

Internal Dimension (mm) | 320*350*450(TH-50) | 400*400*500(TH-80) |

Overall Dimension (mm) | 820*1160*950 | 900*1210*1000 |

Interior Volume | 50L | 80L |

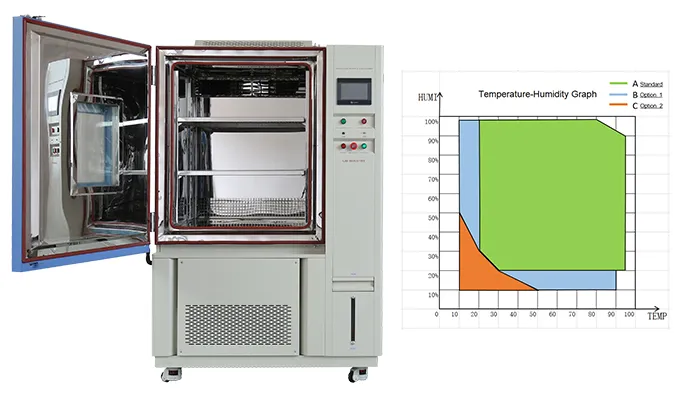

Temperature Range | -20℃/ -40℃/-70℃~ +150 ℃ | |

Temperature Fluctuation | ± 0.5 ℃ | |

Humidity Range | 20% ~ 98% RH | |

Humidity Deviation | ± 2.5% RH | |

Cooling Rate | 1 ℃ / min | |

Heating Rate | 3 ℃ / min | |

Cooling system | Mechanical compression refrigeration system | |

Controller | Programmable color LCD touch screen controller Ethernet connection | |

1. Electronic device and semiconductor packaging and testing, verifying the stability and conduction performance of devices at extreme temperatures.

Typical test pieces: chip packaging body, PCB solder joints, LED packaging, crystal oscillator.

2. Thermal cycling/weather resistance testing of automotive parts to evaluate the service life of components under complex working conditions such as alternating cold and heat and high humidity.

Typical test components: micro motors, on-board sensors, electronic control modules.

3. Environmental aging test for medical devices.

Typical test pieces: disposable electronic medical products, micro pump devices, monitoring sensors.

4. Precision manufacturing and material thermal stress testing

Test objective: To analyze the deformation, failure or delamination of micro-structural components or new materials under heating conditions

Applicable tests: Thermal shock test, temperature and humidity cycling, stress screening (ESS)

Small test pieces are often structurally complex, fragile and expensive. The small benchtop environmental chamber, due to its more concentrated space and higher heat transfer efficiency, can generate significant temperature or humidity stress on small samples in a short time, which is closer to the real environmental failure scenarios.

In addition, this type of chamber can be conveniently integrated into the laboratory test station automated test system or cleanroom environment, not occupying too much space, and can effectively improve the efficiency and repeatability of single-piece tests. It is particularly suitable for small-batch R&D verification or continuous monitoring tests.

If you are looking for a professional, efficient environmental testing device suitable for micro-components, please contact LIB. We will provide you with the best configuration plan that matches your testing requirements.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia