Why Choose the Color Fastness and Durability Xenon Arc Light Chamber

1️⃣ Multi-material color stability testing built into one platform

From textile fibers to automotive dashboards and outdoor coated metals, the color fastness and durability xenon arc light chamber supports diverse geometries and materials, enabling cross-industry UV weatherability comparison without additional equipment.

2️⃣ Real-time monitoring ensures exposure accuracy

Integrated sensors track irradiance, BPT (black panel temperature), humidity, and water spray in real time, preventing fluctuating sunlight simulation and delivering highly reproducible color fastness results.

3️⃣ Energy-optimized xenon lamp extends test runtime

With improved optical filtering and cooling design, the system maximizes lamp life cycle, reducing consumable cost while maintaining precise durability exposure performance.

4️⃣ Advanced water spray and condensation create wet–dry fatigue

The xenon arc light chamber reproduces rain erosion, moisture absorption, and hydrolysis—failure modes critical for outdoor fabrics and polymer components—beyond the capability of standard UV-only testers.

5️⃣ Touchscreen programmable controller simplifies complex standards

Pre-configured test programs aligned with ISO 105-B02, ASTM G155, AATCC TM16, and others allow fast setup, reducing operator learning curve while ensuring consistent, globally compliant test execution.

Core Technical Parameters of Xenon Arc Light Fastness and Weathering Tester

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

Chamber Type | Rotating Holder |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Controller | Programmable color LCD touch screen controller |

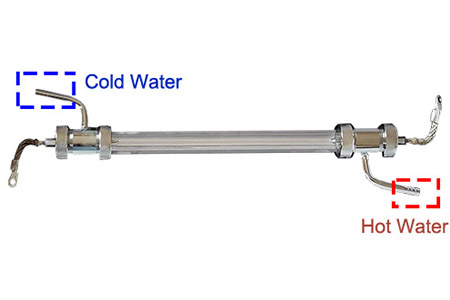

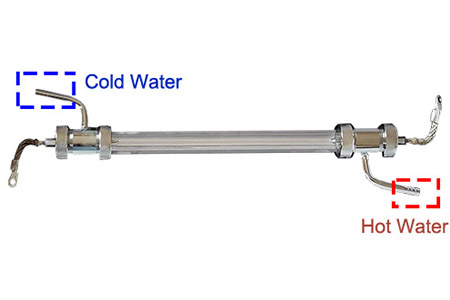

Water supply system | Automatic water supply, Water purification system |

Radiometer | UV Radiometer, Tolerance: ±5% |

Cooling System | Mechanical compression refrigeration system |

Key Details of Color Fastness and Durability Xenon Arc Light Chamber

Xenon Lamp & Full Spectrum Light Source | Power: 4500W water-cooled xenon arc lamp Lifespan: ≥1600 hours Feature: Full-spectrum simulation including UV, visible, and IR light Cooling: Advanced lamp cooling ensures stable temperature and consistent color fastness exposure

|

|

Optical Filter System | Types: Daylight, Window, Extended UV filters Function: Simulates indoor and outdoor sunlight conditions accurately Standards Compliance: ISO 105-B02, ASTM G155, AATCC TM16

|  |

Irradiance & Black Panel Temperature (BPT) Control | |  |

Moisture Cycle & Water Spray System | Humidity Range: 50–98% RH Feature: Programmable wet/dry cycles including rain and condensation simulation Benefit: Replicates real-world conditions that cause coating blistering, mold, and surface degradation

|  |

Specimen Mounting & Capacity | Design: 3 layers rotating sample holder with 42pcs specimen capacity Feature: Ensures 360° uniform exposure Benefit: Allows simultaneous testing of various materials, improving efficiency and data reliability

|  |

Advanced Controller | Interface: User-friendly touchscreen Functions: Pre-programmed cycles, real-time monitoring, precise parameter adjustment Benefit: Simplifies complex tests and ensures compliance with international standards

|  |

Customer Questions – Color Fastness & Durability Testing Made Easy

Q1: How can I quickly test coating durability?

Simulate months of sunlight, UV, and moisture in days. For coatings, LIB also offers salt spray chambers for combined color and corrosion testing.

Q2: Will this help improve product quality?

Yes. Identify fading, gloss loss, or surface degradation early to optimize materials, reduce returns, and ensure customer satisfaction.

Q3: Is it easy to use in production?

Absolutely. Programmable cycles and touchscreen controls make it simple to integrate, with LIB providing tailored support for your workflow.

✅ Ready to Ensure Your Products Stand the Test of Time?

Contact LIB industry today inquiry@libtestchamber.com to discuss your color fastness and durability testing needs and receive a tailored solution within 1~3 hours that guarantees reliable, standard-compliant results.

Fast Delivery | Custom Configurations | 3-Year Warranty & Lifetime Technical Support.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia