In the field of materials science and engineering, xenon arc weatherometers, as a key test equipment, play an indispensable role in assessing the durability and stability of materials under simulated natural environmental conditions. However, due to its working principle and complex operating mechanism, safety must be put first when using the xenon arc weatherometer , and a series of precautions must be strictly followed.

|

|

This guide will show you how to safely operate the chamber, optimize test results, and leverage LIB industry’s expertise for maximum performance and long-term reliability.

The xenon arc chamber generates full-spectrum radiation that closely replicates natural sunlight across UV, visible, and infrared ranges. This enables realistic simulation of outdoor conditions, accelerating aging tests while maintaining highly accurate results.

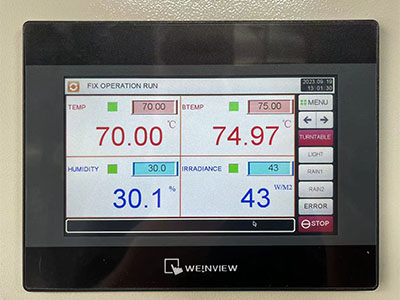

Equipped with precise temperature and humidity sensors, the xenon test chamber continuously monitors environmental conditions, feeding data to an advanced programmable controller. This ensures stable, repeatable testing, compliant with ISO 4892 and ASTM G155 standards.

Safety is essential—not only to protect operators but also to ensure consistent and reliable test outcomes.

– Prevent Shocks, Protect Your Equipment

- Operates at 220V high-voltage; proper grounding is mandatory.

- Inspect cords and plugs regularly; replace damaged components immediately.

- Internal temperatures can rise significantly; wait for stabilization and use protective gear before opening doors.

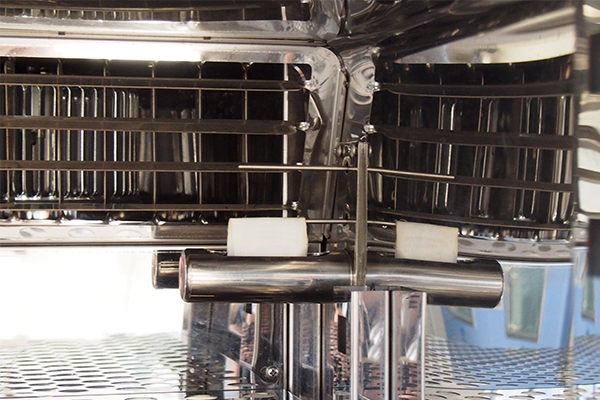

- Fans, turntables, and lamp mechanisms can cause injury. Inspect and maintain regularly, ensuring all guards are in place.

- Verify door locks and seals before testing to prevent accidental exposure to heat and radiation.

- Install in a well-ventilated area with enough space for heat dissipation and maintenance.

- Conducted by qualified technicians following LIB industry instructions.

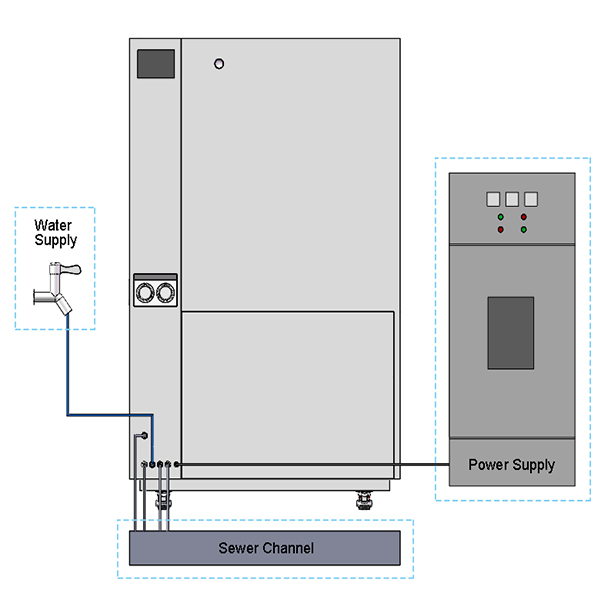

- Ensure secure, leak-free connections for power, water, and drainage.

- Verify lamp voltage/current, light intensity, temperature, and humidity control before the first test.

- Observe for flicker or abnormal lamp behavior and confirm stable environmental readings.

- Oversized or irregular samples can interfere with airflow and light distribution. Ensure samples fit chamber specifications.

- Remove dust, oil, and residues.

- Optional pre-treatment: cleaning, sanding, or coating depending on material and test goals.

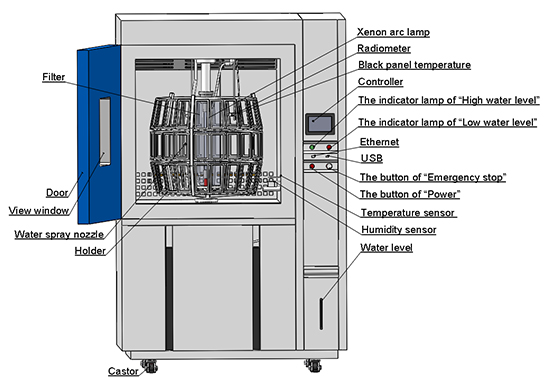

- Operators should be familiar with display screens, control interfaces, and button functions before running tests.

- Key parameters: light intensity, temperature, humidity, test duration.

- Avoid arbitrary adjustments; incorrect settings may invalidate results or damage equipment.

- Observe lamp brightness, sensor readings, airflow, and refrigeration systems during testing.

- Stop immediately if abnormalities occur to prevent further issues.

- Clean lamp surfaces, filters, sample racks, and sinks to prevent contaminant buildup.

- Aging lamps reduce light intensity and alter spectral distribution. Replace per manufacturer recommendations.

- Regularly check temperature and humidity sensors, electrical connections, and heating/cooling systems to ensure stable performance.

· Full-spectrum xenon lamps with ±5% light uniformity

· Programmable controller with remote monitoring for precise control

· Long-lifespan lamps and high-precision optical sensors

· Stable temperature & humidity control system

· Customizable chamber size and test functions

· Compliant with ISO 4892 / ASTM G155 standards

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

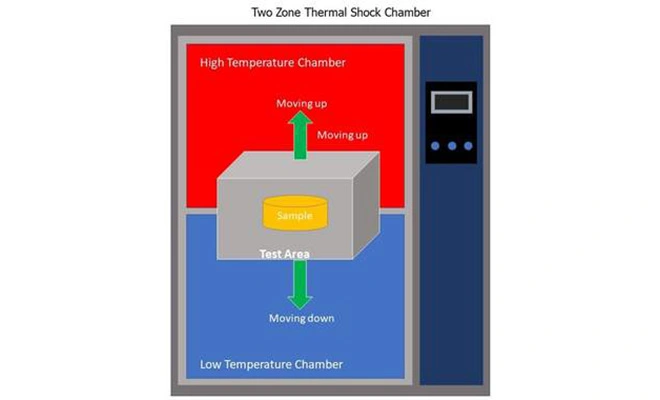

Chamber Type | Rotating Holder |

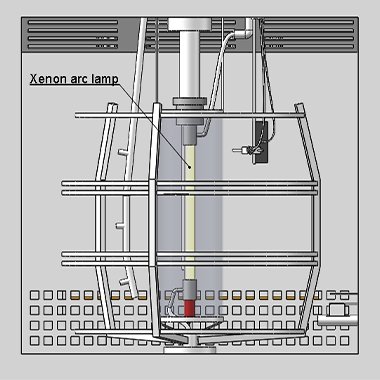

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Controller | Programmable color LCD touch screen controller |

Water supply system | Automatic water supply, Water purification system |

Radiometer | UV Radiometer, Tolerance: ±5% |

Cooling System | Mechanical compression refrigeration system |

|  |

Applications: Automotive exterior plastics, dashboards, coatings, solar panels, construction materials, polymers exposed to sunlight.

1. Precision and reliability – Advanced sensors and controllers maintain stable test conditions.

2. Durability – Long-life lamps and robust chamber design minimize downtime.

3. Compliance – Meets international testing standards.

4. Customization – Chambers tailored to sample size, application, and test protocol.

5. Technical Support – Expert guidance for installation, operation, and maintenance.(3-year extended warranty and lifetime service)

Ensure your materials meet global durability standards with LIB industry Xenon Arc Test Chambers.

· Request a detailed datasheet or quotation

· Free consultation with our engineers

· Tailored test solutions for unique materials and applications

Contact us: inquiry@libtestchamber.com,With LIB industry’s expertise, you gain accuracy, reliability, and peace of mind in every test.

In the field of materials science and engineering, xenon arc weatherometers, as a key test equipment, play an indispensable role in assessing the durability and stability of materials under simulated natural environmental conditions. However, due to its working principle and complex operating mechanism, safety must be put first when using the xenon arc weatherometer, and a series of precautions must be strictly followed.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia