The purpose of this test is to simulate the thermal shock penomenon caused by cold water splashing onto high-temperature systems/components. This situation occurs when driving on slippery roads in winter and is applicable to products in areas where vehicles splash water. Failure modes include mechanical fracture of the material or seal failure caused by different coefficients of expansion at different temperatures.

This article mainly discusses the splash test and immersion test in the ISO 16750-4 standard.

Verify the tolerance capacity and functional stability of the equipment when exposed to cold water splashing under high-temperature working conditions.

For instance, when a vehicle passes through accumulated water, is being washed, or is being washed by rain, the surface of an electronic device is suddenly splashed with cold water.

Applicable to: engine compartment sensors, ABS controllers, and lighting control units

a. Temperature conditions: The equipment is usually preheated to a high-temperature state (such as +85°C or higher), simulating the state in the engine compartment or high-temperature environment.

b. Spray water temperature: The water temperature for splashing is relatively low (such as +23°C ±5°C), causing thermal shock.

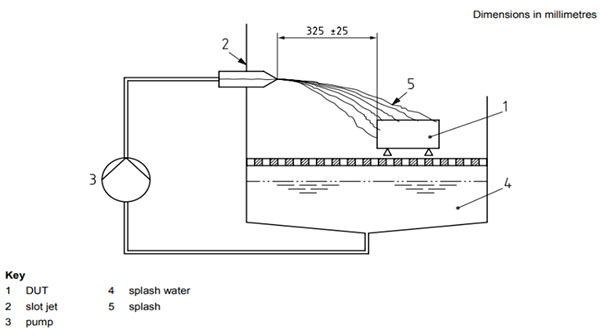

c. Water spraying method: Use specific nozzles or water spraying systems to spray water above the equipment or at specific angles.

d. Frequency/duration: Usually, each cycle lasts for a few seconds, and multiple cycles are carried out with intervals of several minutes.

Confirm whether the equipment can still maintain its sealing performance and the reliability of its electrical functions when it is completely submerged in water under specific time and water depth conditions.

such as vehicles wading through water, heavy rain, and equipment accidentally falling into water.Immersion tests are applicable to: chassis controllers, electric pedal ECUs, water pump control modules, etc.

a. Immersion depth: Usually specified water depths such as 0.1m, 0.5m, 1.0m, etc., depending on the location where the equipment is used.

b. Test duration: The common duration is 30 minutes or longer. Water temperature: The test water temperature is usually +23°C ±5°C, or adjusted according to specific uses.

Before immersion, the equipment may be heated (for example, to +85°C), and then quickly immersed in water to simulate thermal shock.

Or test the status during power-off, power-on and operation.

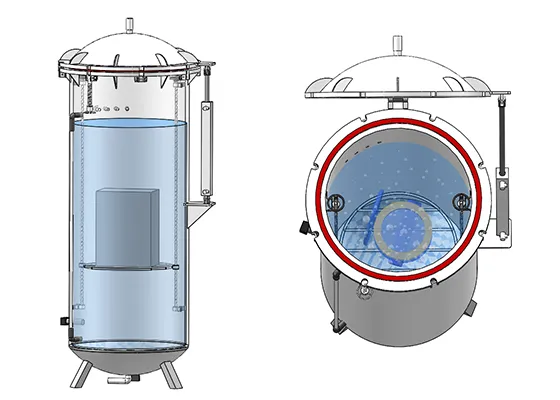

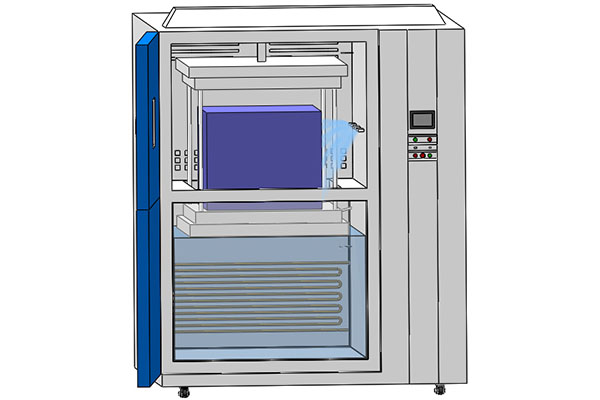

The bottom of the workroom is water, and there are copper tubes in the water that can be used for cooling. The samples are placed in a vertically movable basket. There are nozzles on the right wall of the workroom, and the water can be sprayed on the samples at a specific angle.

This impact chamber can conduct ice water splash shock test, IPX7 immersion test and ice water shock immersion.

If you also have similar cold water impact requirements, please feel free to contact LIB to learn more about product details and design solutions.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia