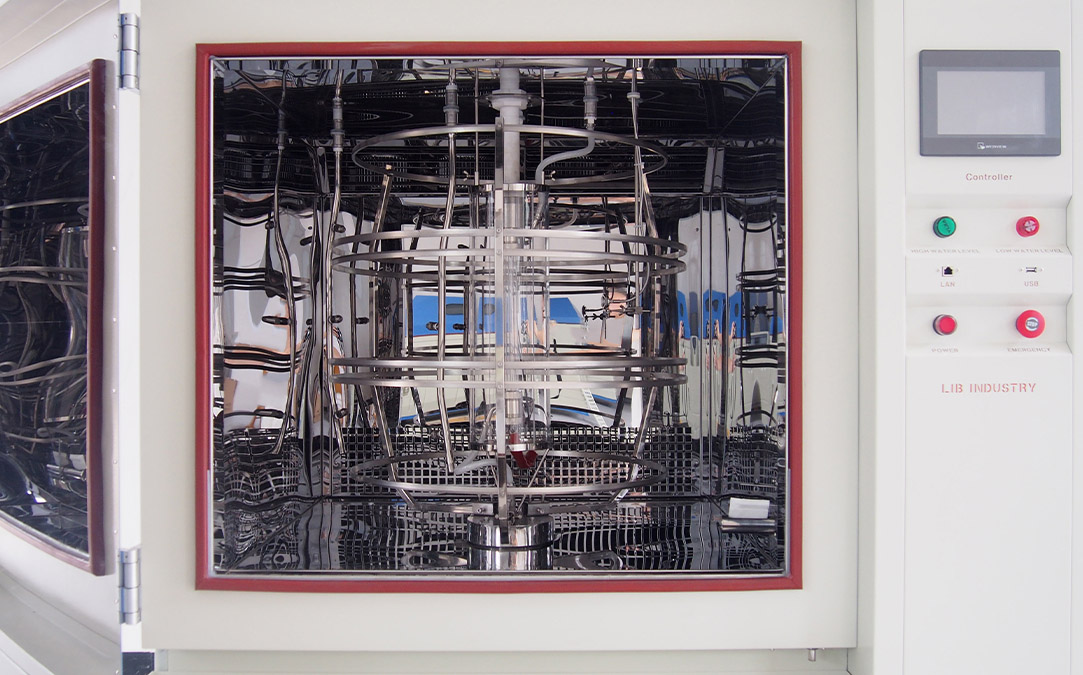

In the field of materials science and product quality inspection, xenon weatherometers play a crucial role. They simulate solar radiation, temperature, humidity, and rainfall, performing accelerated aging tests on materials and products to evaluate weather resistance and service life. This article delves into the principle, structure, characteristics, application fields, and operating steps of the xenon weatherometer, helping you fully understand this key testing equipment.

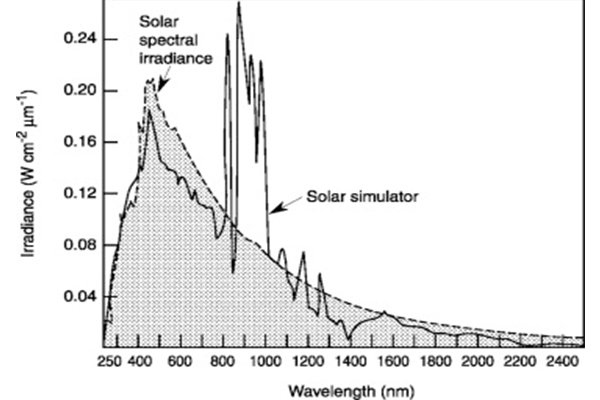

The xenon weatherometer uses xenon lamps (1500–3000 W, 280–800 nm) to reproduce the full spectrum of sunlight, including ultraviolet, visible, and infrared radiation. By precisely controlling irradiation intensity, temperature (–20°C to +80°C ±0.5°C), humidity (20–98% RH ±2%), and spray rainfall (0.1–2 mm/min), it can mimic natural climatic conditions across different regions and seasons.

During testing, the material is exposed to xenon lamp radiation, combined with temperature/humidity cycles and optional rainfall, accelerating the aging process to replicate years of outdoor exposure in just weeks.

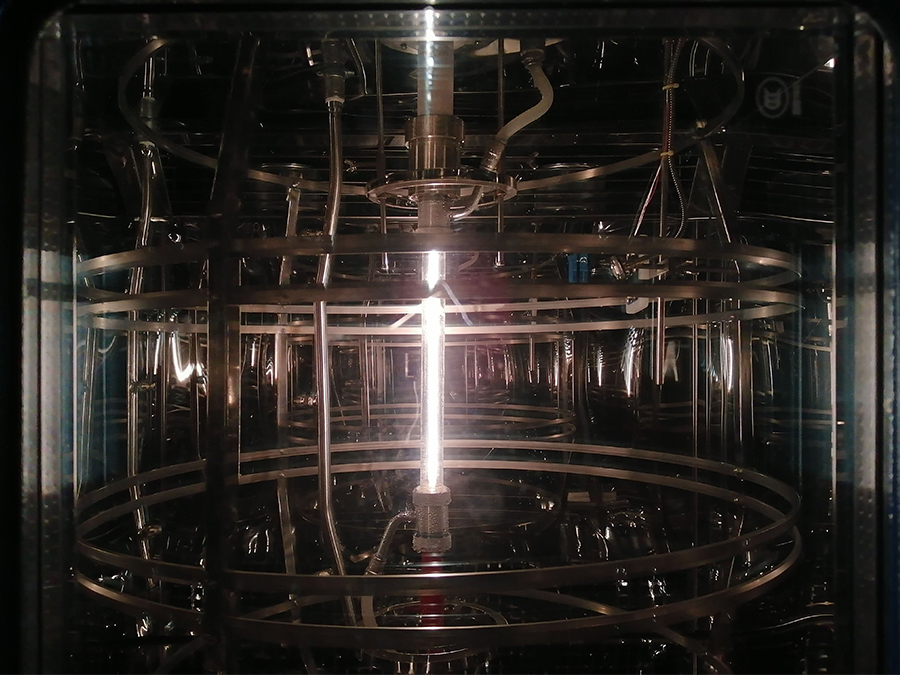

· Type: Long-arc or pulsed xenon lamp

· Power: 1500–3000 W

· Wavelength Range: 280–800 nm, simulates UV, visible, infrared sunlight

· Value: Provides stable, uniform radiation, essential for reliable aging simulation; pulsed mode allows high-intensity momentary stress for specialized tests

· Filters: UV cutoff 280/340/420 nm; optional IR filters

· Function: Adjust spectral distribution to mimic sunlight through atmosphere or enhance UV effects

· Value: Ensures precise simulation of environmental conditions, critical for coatings, plastics, and textiles testing

· Range: –20°C to +80°C, ±0.5°C uniformity

· Heating/Cooling Rate: 1–5°C/min

· Value: Simulates extreme seasonal or regional temperatures, evaluates thermal resistance, deformation, and long-term stability of materials

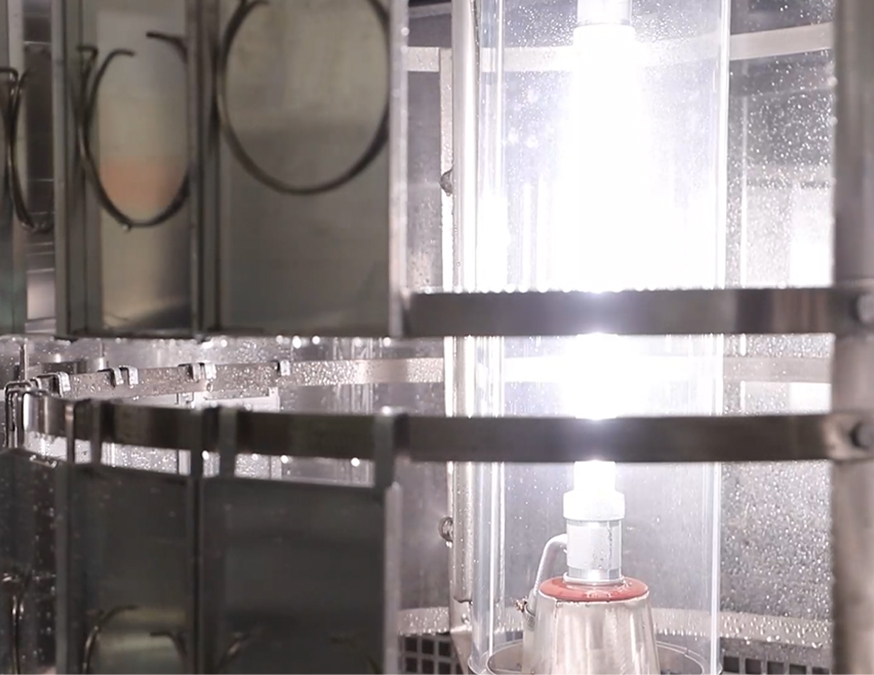

· Range: 20–98% RH, ±2% RH

· Function: Humidification and dehumidification to replicate high/low moisture environments

· Value: Critical for materials sensitive to moisture, like coatings, composites, and rubber products

· Spray Rate: 0.1–2 mm/min

· Spray Interval: 1–60 min

· Value: Simulates rainfall and condensation effects, testing material durability under wet conditions

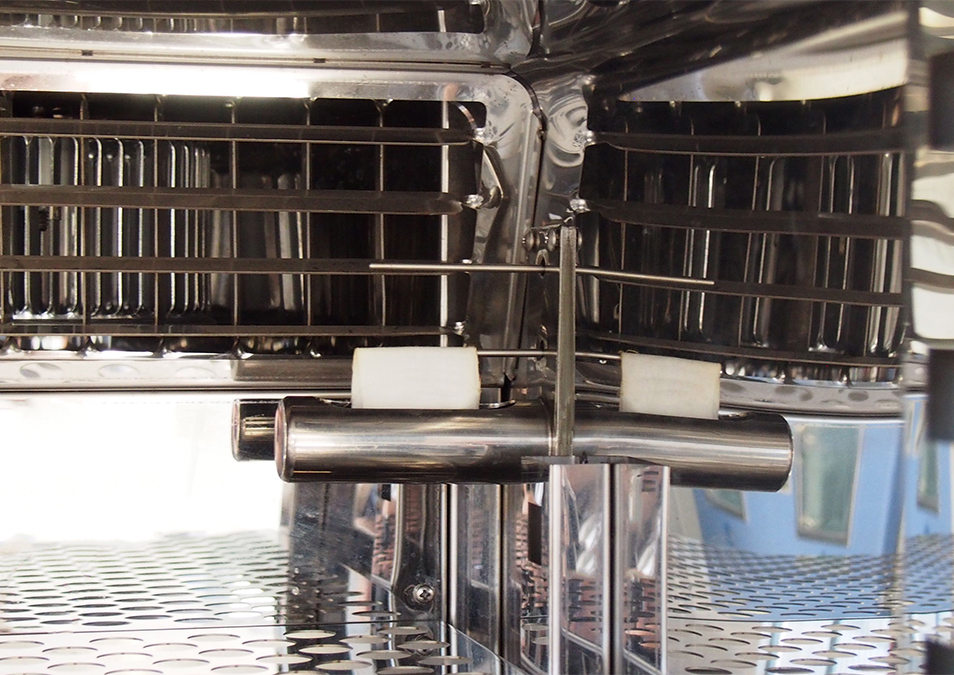

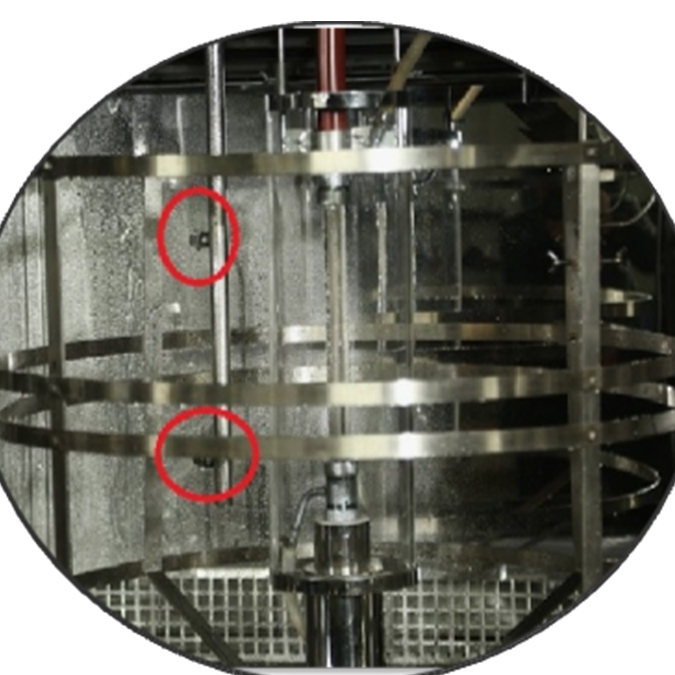

· Rotation Speed: 1–5 rpm

· Airflow Uniformity: ±5%

· Value: Ensures uniform exposure of all sample surfaces, preventing uneven aging and guaranteeing reproducible results

· High-Fidelity Simulation: Full-spectrum light plus precise temperature, humidity, and rainfall control ensures realistic weathering effects.

· Accelerated Aging: Simulate 1–10 years of outdoor exposure in 100–1000 hours, significantly shortening testing cycles.

· Consistent and Repeatable: Parameters like light intensity, temperature, and humidity are fully programmable, producing repeatable results across batches and labs.

· Flexible & Versatile: Adjustable light spectrum, temperature, humidity, and rainfall to meet ISO 4892-2, ASTM G155, GB/T 16422 standards.

· Enhanced Material Insight: Captures color change, gloss loss, mechanical degradation, surface roughness, providing comprehensive material performance data.

1. Plastics & Rubber

· Use Cases: Pipes, films, seals

· Benefit: Evaluate UV, heat, and moisture resistance to ensure outdoor durability

· Standards: ISO 4892-2, ASTM G155

2. Coatings & Paints

· Use Cases: Vehicle paint, building coatings

· Benefit: Assess color change, gloss retention, chalking; optimize formulation

· Standards: ASTM D4303, ISO 11507

3. Textiles

· Use Cases: Outdoor fabrics, technical textiles

· Benefit: Test fading, strength decline, and weather resistance for long-lasting products

· Standards: ISO 105-B02, ASTM D6543

4. Automotive Components

· Use Cases: Bumpers, interior panels, dashboards

· Benefit: Ensure materials withstand UV, temperature, humidity, and rain; maintain appearance and performance

· Standards: SAE J1960, ISO 4892, ASTM G155

1. Sample Preparation

· Clean, dry, and size according to the selected standard (e.g., ISO 4892-2 for plastics)

· Remove contaminants that may affect test results

2. Parameter Settings

· Light intensity: 200–1000 W/m²

· Temperature: –20°C to +80°C ±0.5°C

· Humidity: 20–98% RH ±2%

· Rainfall: 0.1–2 mm/min, intervals 1–60 min

· Cycle duration: 1–1000 hours, programmable to simulate 1–10 years of natural aging

3. Sample Installation

· Mount samples on rotating racks at 1–5 rpm

· Ensure airflow uniformity ±5% for consistent irradiation

4. Test Execution

· Start xenon weatherometer and monitor parameters in real-time

· Record data for irradiation, temperature, humidity, and spray cycles

· Adjust parameters if needed to maintain standard compliance

5. Sample Evaluation

· Examine color change, gloss loss, mechanical properties, surface roughness

· Compare results with untested samples

· Generate a report aligned with relevant standards (ISO 4892, ASTM G155)

Accelerate your product testing and ensure accurate, reliable results with LIB industry xenon weatherometers.

Our Advantages: - One-Stop Service: From consultation, delivery, installation to operation training - Fast Response: Rapid support within 1–3 hours, on-site assistance globally - Comprehensive After-Sales: 3-year warranty + lifetime technical guidance - Custom Solutions: Fully configurable parameters to meet your testing requirements

Contact LIB industry today inquiry@libtestchamber.com to get a tailored solution, request a quote, or download the full technical brochure.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia