In modern electronics and mechanical engineering, thermal testing equipment is indispensable for evaluating how products perform under prolonged or repeated exposure to temperature fluctuations. Particularly for printed circuit boards (PCBs) and mechanical devices, temperature cycle testing is a standard approach to simulate real-world environmental stresses—helping manufacturers detect failure points early in development.

Thermal cycle testing, also known as temperature cycling, involves repeatedly exposing a product to alternating high and low temperatures over a specific number of cycles. This method evaluates the effects of thermal expansion and contraction, revealing weaknesses such as solder fatigue, material warping, seal degradation, and connector failure.

It’s widely used in industries such as automotive, aerospace, electronics, energy, and defense to ensure long-term durability and compliance with standards like IEC 60068-2-14 and MIL-STD-810H.

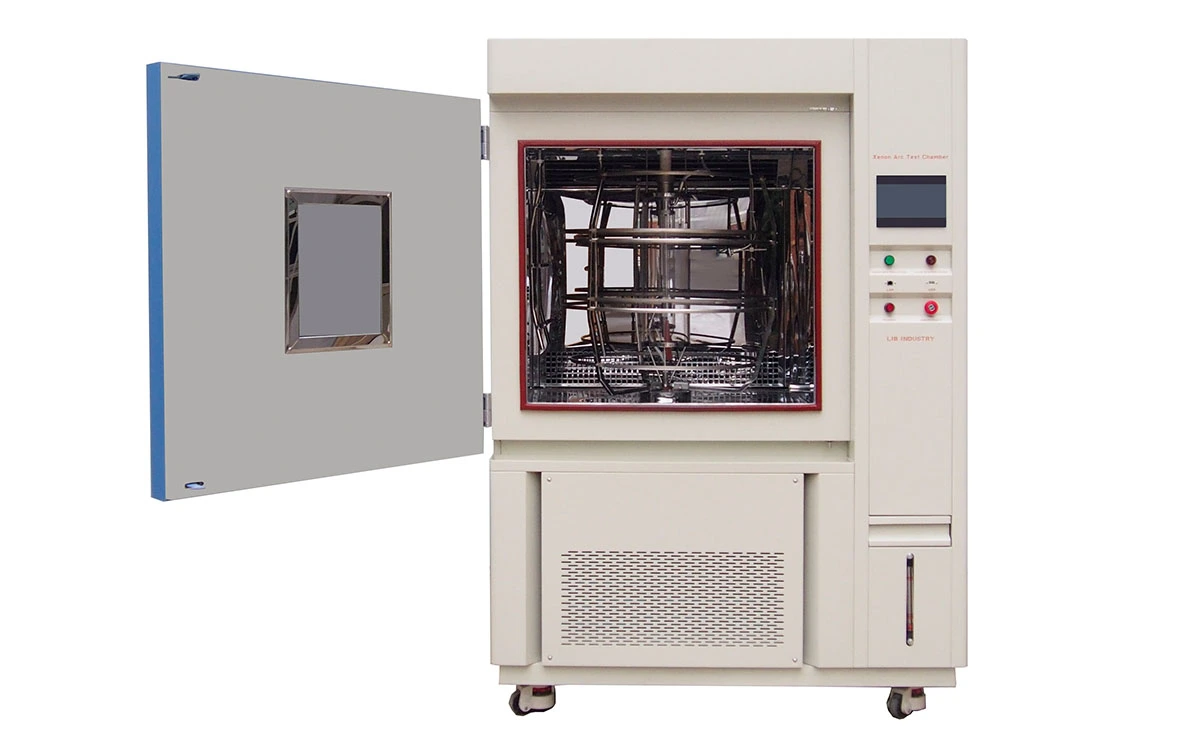

LIB’s thermal cycling equipment is engineered to provide accurate, repeatable, and programmable thermal conditions for testing a wide variety of components.

Designed with robust temperature control systems, uniform airflow, and intelligent software, it is ideal for both development labs and production quality assurance.

Key Technical Features: | Temperature Range: -70°C to +150°C Ramp Rate: Up to 5°C/min (customized) Temperature Uniformity: ±1.5°C Control System: LIB touchscreen controller with multi-segment programmable profiles Data Logging: USB and Ethernet support for remote monitoring and data export Standard Volumes: 50L to 1000L (custom sizes available,benchtop types to walk-in types)

|

| |

This equipment allows users to define precise temperature profiles with dwell times, cycle counts, and transition rates—perfect for simulating field conditions over time.

PCBs: Solder joints, vias, and PCB substrates are prone to thermal fatigue. LIB thermal chambers help engineers test the reliability of multilayer boards, BGA packages, and SMD components under long-term cyclic stress. | a common testing profile for PCBs may involve 1000 cycles from -40°C to +125°C, with a 10-minute dwell at each extreme and a transition ramp of 5°C/min.

|  |

Mechanical Devices: Such as housings, seals, gear assemblies, and enclosures experience stress during thermal expansion and contraction. Thermal cycling tests help predict deformation, cracking, and functional degradation over time. | For moisture-sensitive mechanical devices, humidity can also be added, such as maintaining 85% RH at 85°C for 168 hours prior to cycling. Such detailed profiles help validate both thermal and hygrothermal endurance of the components. |  |

One of LIB’s major advantages is its ability to customize test ports (feedthroughs) to accommodate cables, sensors, power lines, fluid pipes, or rotating shafts—without compromising the chamber’s thermal integrity.LIB thermal cycling chambers are designed so that specimens can operate during the test, allowing engineers to observe failure modes under real-world working conditions.

Position: Side wall, rear panel, or top

Size: 50mm, 100mm, or customer-defined diameters or shape

Quantity: Single or multiple ports based on test complexity

This is particularly useful for in-situ monitoring, where the test specimen is powered or transmitting data during cycling.

LIB’s thermal testing equipment is widely used in:

Automotive: Battery modules, ECUs, connectors, lighting assemblies

Aerospace: Sensors, actuators, avionic control boards

Consumer Electronics: Smartphones, routers, circuit modules

Energy Systems: Solar inverters, control panels

Defense: Communications equipment, ruggedized electronics

By identifying failure mechanisms early, companies can avoid costly field returns and improve product reliability.

With nearly two decades of experience in environmental test equipment, LIB is a trusted name in thermal cycling chambers. We offer not only high-performance standard models but also fully customizable solutions—from chamber size and temperature profile settings to port configuration and integration with test benches.

Each chamber is designed to meet international standards while offering long-term stability, low maintenance, and easy operation.If you are testing PCBs, mechanical devices, or electronic assemblies, LIB offers the precision, flexibility, and support your lab needs to succeed.Please feel free to leave your testing requirements. The LIB team will contact you shortly.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia