Salt spray testing—also known as neutral salt spray (NSS) or salt fog testing—is an accelerated corrosion method designed to simulate the effects of a harsh, chloride laden environment on metals, coatings, and assembled products. In a sealed salt spray chamber , a fine mist of 5% sodium chloride solution is continuously or cyclically sprayed over test specimens at elevated temperatures. By condensing months or years of natural outdoor exposure into days or weeks, salt spray tests provide rapid, reproducible insights into coating adhesion, plating integrity, galvanic compatibility, and substrate durability.

Salt spray results inform material selection, surface treatment processes, and quality control standards across industries—from automotive and aerospace to electronics and building materials. To ensure consistency, most salt spray protocols comply with standards such as ASTM B117, ISO 9227, IEC 60068-2-11, and SAE J2334.

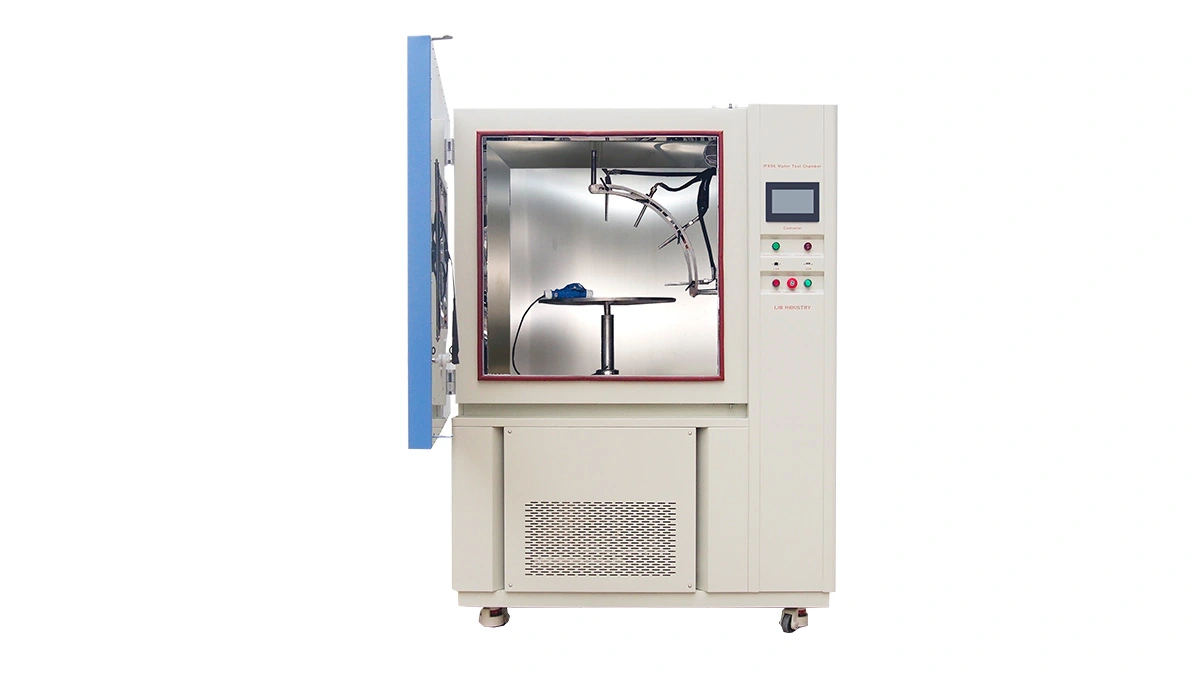

LIB offers three core series—S, SC, and SSC—each engineered for progressively more rigorous corrosion tests:

Functionality: Continuous or timed salt fog without active humidity control.

Temperature Control: Ambient to +60 °C (±0.5 °C).

Fog Deposition: 1–2 mL per 80 cm² per hour.

Optional models: S-150, S-250, S-750, S-010, S-016, S-020

The S Series salt spray chamber is ideal for straightforward pass/fail assessments of basic corrosion resistance and serves as an entry-level chamber for QC labs.

Functionality: Alternates salt fog, drying, and controlled humidity phases for realistic environmental cycling.

Humidity Range: 30–98% RH; temperature +10 → +90 °C.

Programmability: Up to 100-step test profiles with variable dwell times.

By including drying intervals, the SC Series cyclic corrosion test chamber reveals corrosion mechanisms—such as filiform undercutting and blistering—that pure salt fog alone may not detect.

Functionality: Integrates neutral salt spray, humidity control, and sulfur dioxide injection for Kesternich (ASTM G85 Annex 4) testing.

Gas Dosing: Programmable SO₂ concentration in ppm.

The SSC Series salt fog and SO2 corrosion chamber pushes the envelope by simulating combined chloride and acid gas attack—critical for materials used in power plants, city rail systems, and offshore platforms.

Understanding that standard chambers cannot satisfy every specialized test, LIB offers three major custom solutions:

Proper specimen mounting is essential for consistent test results. While LIB’s default Holder uses six stainless-steel round bars with five V-grooves, custom fixtures include:

Insert-Type Holders: Slide-in panels for PCBs, thin metal coupons, or textile samples.

3D Frame Holders: Laser-cut frames accommodating irregular shapes—bicycle frames, automotive brackets, complex castings.

Hook-Style Holders: Corrosion-resistant hooks for hanging cables, pipes, or tubular samples.

Flat-Plate Holders: Horizontal support plates for sheet-metal panels or solar-cell modules.

All custom holders are fabricated from non-reactive, acid-resistant alloys to preserve fog uniformity and prevent holder-induced artifacts.

For full-size assemblies—such as chassis subframes, wind-turbine blades, or large marine components—LIB’s walk-in chambers provide:

Custom Dimensions: Tailored interior volumes to suit oversized products or multiple batches.

Heavy-Duty Insulated Doors: Pneumatic or manual operation with safety interlocks to minimize fog loss.

Loading Carts/Rail Systems: Ergonomic solutions for safe transport and positioning of heavy specimens.

Multi-Mode Testing: Supports NSS, AASS (acidified acetic), CASS (copper accelerated), and cyclic protocols.

Certain industries require simultaneous environmental stresses plus stringent safety compliance. LIB offers:

Dual-Mode Operation: Rapid switching or programmed overlap of temperature/humidity cycles and salt fog.

Integrated PLC Control: Multi-stage sequencing, alarm notifications, and remote monitoring via Ethernet.

These advanced configurations are indispensable for petrochemical R&D, battery material testing, and any application where both corrosive and thermal shocks occur in safety critical contexts.

At LIB, we’re more than an equipment supplier—we are your corrosion-testing partner. Our turnkey approach includes:

Consultation & Design: Requirements analysis, 3D chamber mockups, tailored proposals.

Installation & Training: On-site commissioning by certified engineers and comprehensive operator instruction.

After-Sales Care: 3-year warranty on all chambers and components, lifetime technical support via hotline or remote diagnostics, and optional preventive maintenance contracts.

Whether you need a fundamental NSS chamber or a bespoke, explosion-proof, multi-environment system, LIB provides precision-engineered solutions backed by decades of expertise.

Ready to elevate your corrosion testing? Partner with LIB for customized salt spray chambers that meet your exact specifications—complete with one‐stop service, a three‐year warranty, and lifetime support.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia