When it comes to accelerated weathering and UV aging testing, UVA-340 fluorescent lamps have emerged as the gold standard. These lamps are designed to closely simulate the ultraviolet portion of natural sunlight, making them essential for evaluating the durability and lifespan of materials exposed to outdoor environments. In this article, we’ll explore the benefits of UVA-340 lamps, why they are preferred in UV aging chambers, and how LIB’s UV test chambers provide industry-leading performance.

UVA-340 fluorescent lamps produce a narrow band of UV radiation primarily in the 295 to 365 nm range, with a peak at 340 nm. This closely replicates the short-wave UV spectrum of sunlight, particularly the UV-A region responsible for polymer degradation, color fading, and surface cracking.

Unlike other UV sources, UVA-340 lamps do not emit UV-B or UV-C wavelengths, which are not present in natural sunlight. This ensures that the testing process is both accurate and realistic, providing a high correlation with real-world conditions.

Their precise wavelength output also allows for controlled laboratory simulations that mimic years of natural sunlight exposure in a fraction of the time, providing engineers and researchers with reliable data on material performance and longevity.

Additionally, the use of UVA-340 lamps reduces the risk of overexposure to artificial UV types not present in sunlight, ensuring that degradation patterns observed during testing closely match those seen in real-world environments.

UVA-340 lamps provide the closest match to natural sunlight in the short-wave UV range, allowing precise accelerated weathering simulations. They effectively replicate sunlight-induced effects such as color fading, surface cracking, and material embrittlement, ensuring test outcomes are meaningful.

Their stable spectral output guarantees reproducible results, with ±2% irradiance variation, reducing test uncertainty. This consistency is crucial for R&D comparisons, regulatory compliance, and quality assurance processes, providing confidence in test reliability.

Standardized exposure ensures different materials are tested under identical conditions, improving R&D insights and product comparisons. This allows manufacturers to make informed decisions on material selection, coatings, and additives that extend product lifespans.

Each lamp offers up to 1,600 hours of service life, lowering maintenance downtime by ~30% and reducing operational costs. Energy efficiency also reduces lab electricity consumption while maintaining consistent test performance.

Compatible with both UVA-340 and UVB-313 lamps, enabling flexible test configurations for multiple standards. Users can simulate different environmental conditions, including high-intensity sunlight exposure or accelerated material degradation tests, without changing the chamber.

UVA-340 testing is widely adopted in industries where long-term material stability is critical:

· Automotive: plastic parts, interior trims, coatings, and dashboard components

· Construction: roofing materials, sealants, insulation, and exterior finishes

· Electronics: housings, connectors, outdoor electronic devices, and enclosures

· Packaging: films, labels, printed materials, and protective coatings

· Paints and Coatings: automotive, industrial, and decorative paints

Industry Example: Automotive OEMs use LIB Industry UV Aging Chambers to ensure plastic trims and coatings withstand years of sun exposure, minimizing warranty claims and improving product reliability. Similarly, construction manufacturers validate roof membranes and sealants for long-term weather resistance, while electronics companies ensure outdoor enclosures resist UV-induced cracking and discoloration.

These UV test chambers are also invaluable for accelerated R&D testing, helping companies bring durable products to market faster and with confidence in their long-term performance.

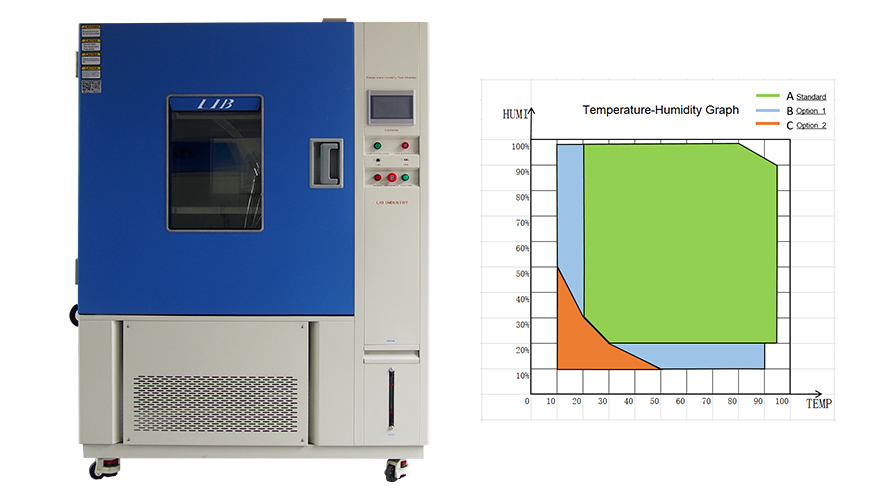

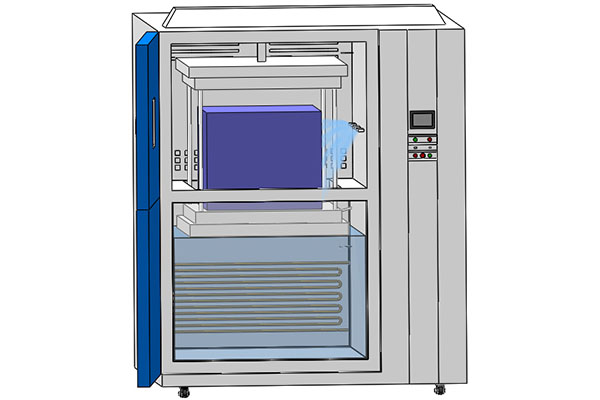

LIB, specializing in advanced environmental test chambers, and our UV Aging Chambers are equipped with high-performance UVA-340 fluorescent lamps.

These UV test chambers are engineered to meet international testing standards such as ASTM G154 and ISO 4892-3, ensuring compliance and consistent quality.

- Supports installation of 8 fluorescent UV lamps for high-intensity exposure

- Compatible with both UVA-340 and UVB-313 lamps, allowing flexible test configurations

- Uniform UV light distribution for consistent sample exposure

- Precise temperature and humidity control for reliable test conditions

- Durable stainless steel structure and corrosion-resistant components

- User-friendly touchscreen controller with programmable light/dark cycles

Model | UV-SI-260 | |||

Internal Dimension (mM) | 450*1170*500 | |||

Overall Dimension (mM) | 610*1330*1470 | |||

Specimen Holder Size(mm) | 75*150 | |||

Specimen Capacity | 56pcs | |||

Irradiation Source | Fluorescent UV lamps (8) - 40 W | |||

Irradiance control | 0.3~20 W/㎡ | |||

Bandwidth | 290 ~ 400nm | |||

Temperature Range | Ambient ~ 90 ℃ ±2℃ | |||

Black Panel Temperature (BPT) | 35 ~ 80 ℃ | |||

Humidity Range | ≥95% RH | |||

By integrating UVA-340 lamps into UV aging systems, LIB delivers the ideal solution for simulating long-term UV degradation in a short time frame. The ability to switch between UVA and UVB lamps makes LIB UV test chambers highly versatile for different testing standards and product requirements.

LIB Industry UV Aging Chambers are designed to meet international standards such as ASTM G154 and ISO 4892-3, ensuring test results are accepted worldwide and comply with regulatory requirements. The chambers’ modular design allows for future upgrades, including additional lamp configurations or increased sample capacity.

Contact LIB Industry now to customize a UV aging chamber tailored to your testing requirements.

UVA-340 fluorescent lamps have become the gold standard for accelerated weathering and UV material durability testing. Their accurate sunlight simulation, consistent performance, and long lifespan make them indispensable for modern materials testing.

By choosing LIB Industry UV Aging Chambers, you gain: - High reproducibility and precise control

- Versatile testing for multiple standards

- Reduced maintenance and operational costs

- Enhanced product development efficiency, enabling faster iterations and more reliable materials selection - Comprehensive environmental simulation, including UV, temperature, and humidity cycles

Explore LIB Industry’s full range of UV Aging Chambers today and experience the industry benchmark in environmental simulation. Request a consultation or free demo to see the difference yourself!

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia