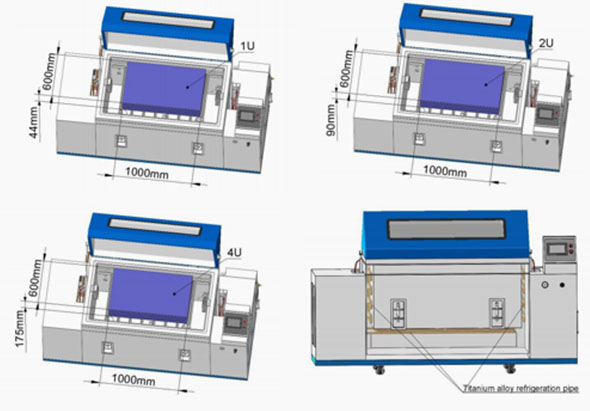

In January 2023, a customer consulted LIB industry for a comprehensive corrosion testing solution dedicated to server reliability evaluation. The test objects included servers with multiple form factors (1U, 2U, and 4U), all required to operate under powered-on conditions during testing.

To accurately simulate real operating environments, the customer required both:

Cyclic salt corrosion testing, and Mixed toxic gas corrosion testing,

with strict requirements on heat load management, gas compatibility, internal structure flexibility, and long-term operational stability.

Compared with conventional corrosion testing, this project presented several technical challenges:

High internal heat load (≈ 5000 W) generated by powered servers

Multiple server heights requiring flexible internal layout

Simultaneous operation of multiple 4U servers

Multi-gas corrosion testing with strict safety and concentration control

Long-duration testing with stable and repeatable conditions

LIB industry addressed these challenges through engineering-level customization, rather than standard equipment configuration.

During powered-on testing, uncontrolled heat accumulation can significantly affect salt corrosion results. To maintain stable environmental conditions, LIB industry redesigned the cooling structure of the SOM-036.

Titanium alloy refrigeration tubes installed on the sidewalls of the workroom

High corrosion resistance suitable for continuous salt spray exposure

Optimized airflow circulation to counteract thermal accumulation

Reliable temperature stability throughout the test cycle

Item | Specification |

Internal Volume | 360 L |

Temperature Range | Ambient ~ +50 °C |

Temperature Uniformity | ≤ ±2.0 °C |

Salt Solution | 5% NaCl (customizable) |

Spray Mode | Continuous / Cyclic |

Heat Load Compensation | Up to 5000 W |

Cooling Structure | Titanium alloy refrigeration tubes |

Control System | PLC + touchscreen, programmable |

Salt Spray Cyclic Corrosion Tester Salt Spray Corrosion Test Chamber Salt Fog and SO2 Corrosion Chamber

|  |

This configuration ensures accurate corrosion evaluation even when servers remain fully operational during testing.

The customer required the mixed toxic gas test chamber to support multiple corrosive gases and simultaneous powered operation of servers.

Install at least 5 × 4U servers

All servers powered on during the test

Support multiple toxic gases, including:

H₂S, SOx compounds, Cl₂, NH₃ (ammonia), and O₃ (ozone)

Item | Specification |

Internal Volume | 1000 L |

Temperature Range | +15 °C ~ +35 °C |

Humidity Range | 50% ~ 85% RH |

Gas Types | H₂S, SOx, Cl₂, NH₃, O₃ |

Gas Control | Independent, programmable |

Server Capacity | ≥ 5 × 4U servers |

Powered-On Testing | Supported |

Gas Mixing System | High-precision mass flow control |

Safety Protection | Gas detection + exhaust treatment |

Data Management | Automatic recording & alarm |

SO2 and Humidity Temperature Chamber

|  |

This system provides uniform gas distribution, precise concentration control, and a safe testing environment for long-term corrosion evaluation.

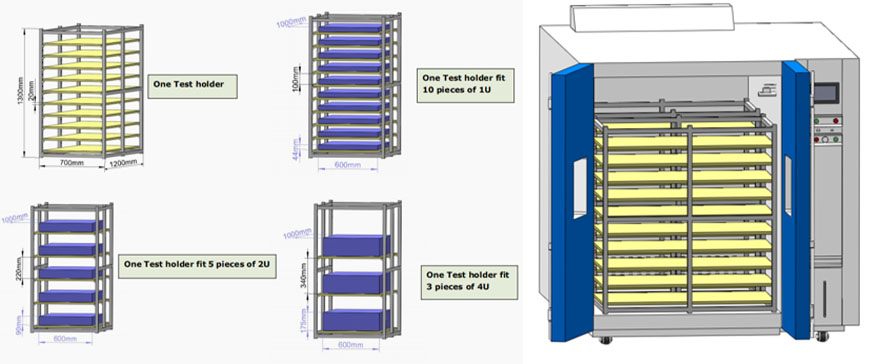

To accommodate servers of different heights, LIB industry specially designed a detachable shelving system, featuring:

Adjustable installation height

High load-bearing performance

Easy disassembly and reconfiguration

Improved airflow and corrosion consistency

This modular design allows the same chamber to support future server models without structural modification.

September 2023: Customer purchased customized SOM-036 & SC-010U

December 2023: Equipment delivered and accepted

After successful operation, the customer placed a repeat order through another supplier

January 2024: Equipment officially put into service

Customer has confirmed future procurement plans

Repeat purchasing strongly validates LIB industry’s product stability, engineering capability, and customization expertise.

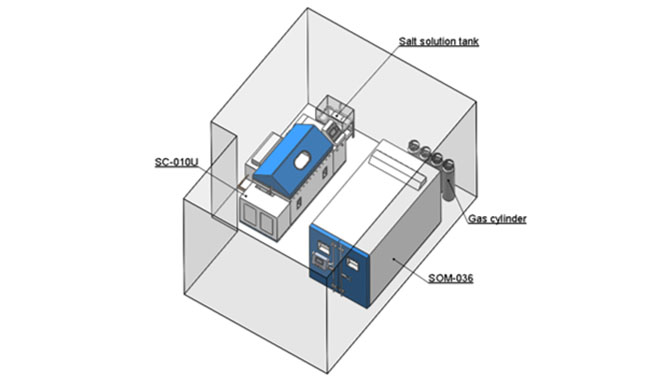

Based on the customer’s laboratory conditions, LIB industry provided professional layout planning, including:

Chamber positioning and spacing

Safety zoning for toxic gas testing

Operation and maintenance access optimization

This one-stop service helps customers reduce installation risk and shorten commissioning time.

Proven experience in powered-on corrosion testing

Strong capability in high heat load management

Deep customization for structure, gas systems, and control logic

Reliable, repeatable, and standard-aligned performance

Comprehensive after-sales technical support

This project demonstrates how LIB industry transforms complex server corrosion testing requirements into reliable and scalable solutions. From cyclic salt corrosion to mixed toxic gas exposure, LIB industry continues to support global customers with professional, customized environmental test systems.

Contact LIB industry today inquiry@libtestchamber.com to discuss customized corrosion test chambers for servers, electronics, and high-reliability applications.

3-Year Warranty | Engineered-to-Order | Lifetime Technical Support

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia