Determining the shelf life of processed food products is one of the most critical challenges food manufacturers face when launching a new product or modifying an existing formulation. For non-perishable foods in particular, quality deterioration may take months or even years to appear under normal storage conditions, making traditional verification methods time-consuming and commercially risky.

Without scientifically controlled testing, shelf life is often estimated rather than verified. Inaccurate shelf life decisions can lead to premature product recalls, regulatory issues, or unnecessary conservatism that shortens market competitiveness. This is why controlled environmental simulation has become an essential tool in modern food quality evaluation.

A food shelf life testing climate chamber provides a reliable solution by recreating precise temperature and humidity conditions to evaluate food stability, safety, and quality degradation over time.

Food shelf life is not determined by formulation alone. It is strongly influenced by external environmental factors encountered during storage, transportation, and distribution, including:

Temperature variations

Humidity exposure

Sunlight or light sensitivity

Packaging integrity and damage

Distribution conditions and points of sale

Among these, temperature and humidity are the most critical and measurable variables. Even small fluctuations can significantly affect microbial growth, moisture migration, texture, flavor, and overall product stability.

Without controlled environmental simulation, it is impossible to accurately assess how food products will perform over time. A food shelf life testing climate chamber eliminates these uncertainties by providing stable, repeatable conditions that reflect real-world storage environments.

A food shelf life testing climate chamber is a professional environmental simulation system designed to reproduce real or accelerated storage conditions for food products. By precisely controlling temperature, humidity, and exposure duration, the chamber enables manufacturers and laboratories to observe physical, chemical, and microbiological changes under repeatable conditions.

Unlike basic storage rooms or uncontrolled incubators, a climate chamber ensures long-term environmental stability, making it suitable for both real-time shelf life studies and accelerated aging tests. It is widely used for packaged foods, snacks, beverages, dairy products, functional foods, and other processed food categories where shelf life validation is essential.

A food shelf life testing climate chamber supports both accelerated and real-time testing methods within a single system.

For foods with high water activity, test conditions such as temperatures around 37–38 °C—which are favorable for microbial growth—can be applied to accelerate quality changes and observe deterioration trends within a shorter timeframe.

For foods with low water activity, products are typically stored at elevated temperatures with controlled humidity levels below 80%, allowing manufacturers to monitor moisture changes, packaging performance, and long-term stability.

By combining accelerated testing with real-time verification, manufacturers can balance testing efficiency with accuracy, making informed shelf life decisions based on reliable data.

LIB industry designs food shelf life testing climate chambers specifically for long-term food stability evaluation, combining precise environmental control with robust structural reliability.

Precise Temperature and Humidity Control

The chamber maintains stable temperature and humidity conditions throughout extended testing periods, ensuring consistent exposure for all samples. This stability is critical for identifying gradual quality changes and avoiding test result distortion caused by environmental fluctuations.

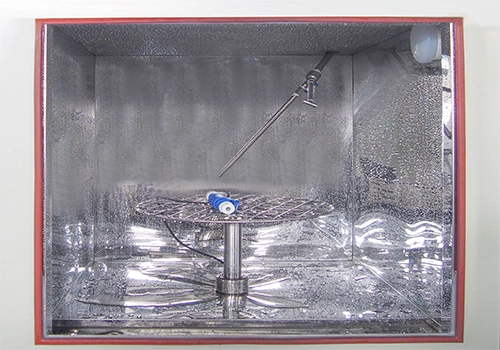

Uniform Air Circulation for Consistent Results

An optimized air circulation system ensures uniform temperature and humidity distribution inside the workspace. This prevents localized differences between samples and improves test repeatability, especially during long-term or batch testing.

Food-Grade Test Workspace

The interior workspace is constructed from SUS304 stainless steel, offering corrosion resistance under high humidity conditions and easy cleaning for food testing environments. This design supports hygienic operation and long service life.

Flexible Capacity and Configuration

LIB industry offers multiple standard chamber volumes ranging from laboratory-scale testing to larger batch evaluation, with adjustable shelving to accommodate various packaging types and sample quantities. Customized configurations are available to match specific testing requirements.

| Name | Food Shelf Life Climate Chamber | ||||

Model | TH-100 | TH-225 | TH-500 | TH-800 | TH-1000 |

Capacity | 100L | 225L | 500L | 800L | 1000L |

Temperature range | -20℃ ~+150 ℃ | ||||

Low type | A: -40℃ B:-70℃ C -86℃ | ||||

Temperature fluctuations | ± 0.5 ℃ | ||||

Humidity Range | 10%~95% | ||||

Heating rate | 3 ℃ / min | ||||

Cooling rate | 1 ℃ / min | ||||

Controller | Programmable color LCD touch screen controller, Multi-language interface, Ethernet , USB | ||||

Interior material | SUS304 stainless steel | ||||

Standard configuration | 1 Cable hole (Φ 50) with plug; 2 shelves | ||||

| Timing Function | 0.1~999.9 (S、M、H) settable | ||||

|

| ||||

Food shelf life testing climate chambers are widely used across the food industry, including:

Processed and packaged foods

Snack and bakery products

Dairy and beverage testing

Functional and health food development

Food R&D centers and quality control laboratories

These chambers support product development, quality validation, packaging optimization, and regulatory compliance throughout the product lifecycle.

Accelerated food shelf life testing commonly uses elevated temperatures, such as around 37–38 °C, to promote faster quality changes and microbial activity. The exact temperature depends on the type of food, water activity, and testing objectives, and is typically combined with controlled humidity settings.

The duration of food shelf life testing varies by method. Real-time testing follows normal storage conditions and may take several months or longer, while accelerated testing in a climate chamber can significantly reduce the testing period by simulating intensified environmental conditions.

Yes. A food shelf life testing climate chamber can be used for a wide range of food products by adjusting temperature, humidity, and test duration. Different packaging types, moisture levels, and storage conditions can be evaluated within the same chamber through programmable settings.

Food shelf life testing typically requires a wide humidity range, depending on the product type. High-humidity conditions are used for moisture-sensitive or high water activity foods, while lower humidity levels are applied to evaluate dry or packaged products. Precise humidity control is essential for reliable results.

LIB industry provides CE-approved systems designed for long-term stability testing, with a focus on durability, accuracy, and application-oriented performance.

With multiple standard chamber capacities, flexible temperature and humidity ranges, and customization support, LIB industry helps food manufacturers and laboratories build dependable shelf life testing processes that align with real storage conditions.

Backed by a 3-year warranty, lifelong technical support, and a 24/7 English-speaking service team, LIB industry ensures stable operation throughout long-term shelf life studies. With globally stocked spare parts and professional commissioning support, downtime is minimized and testing continuity is fully protected.Contact LIB industry inquiry@libtestchamber.com to discuss your testing requirements and configuration needs.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia