UV Accelerated Weathering Chamber Features and Benefits

1. Accelerated aging in a short time

Simulates material degradation caused by UV radiation, temperature, and humidity in a relatively short period, allowing users to replace long-term outdoor exposure with efficient laboratory testing and significantly shorten product validation cycles.

2. High correlation with real outdoor environments

Accurately simulates ultraviolet radiation, rain, dew, and moisture effects commonly encountered outdoors, ensuring that test results are closer to real service conditions.

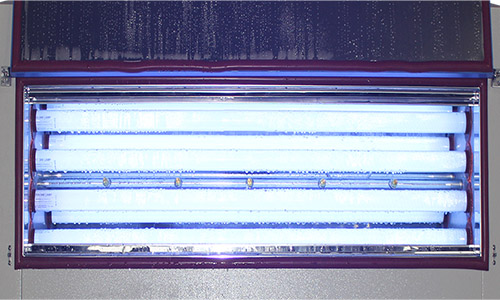

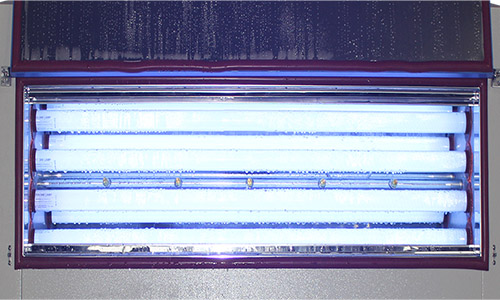

3. Professional UV lamp system

Equipped with UVA-340 and UVB-313 lamps, UVA-340 lamps simulate more powerful short-wave ultraviolet light, UVB-313 lamps have higher energy, and the sample can receive ultraviolet radiation evenly.

4. Durable and corrosion-resistant chamber structure

The inner chamber is made of SUS304 stainless steel, offering excellent corrosion and high-temperature resistance. The exterior uses coated steel plate to enhance structural strength and long-term operational stability.

UV Accelerated Weathering Chamber Specifications

Model | UV-SI-260 |

Internal Dimension (mm) | 450*1170*500 |

Overall Dimension (mm) | 610*1330*1470 |

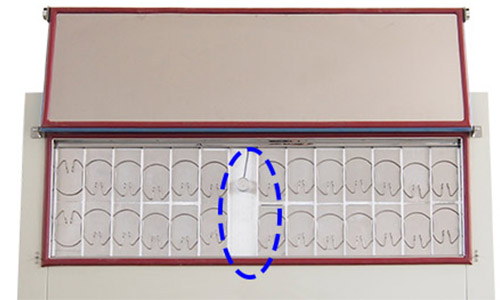

Specimen Holder Size(mm) | 75*150 |

Specimen Capacity | 56 Pieces |

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

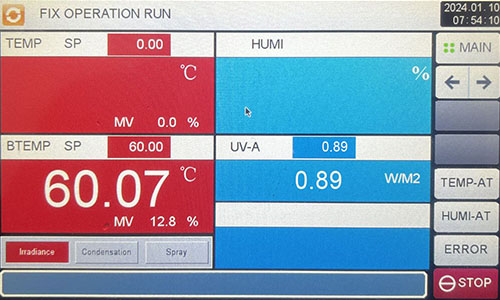

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Distance of Specimen and lamp | 50mm |

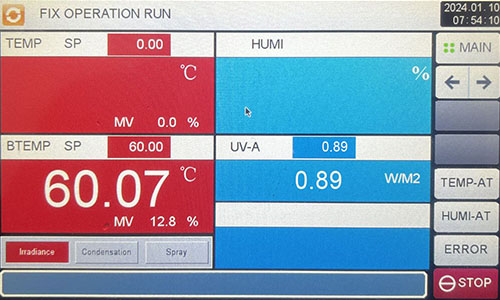

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water Supply System | Automatic water supply, Water purification system |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

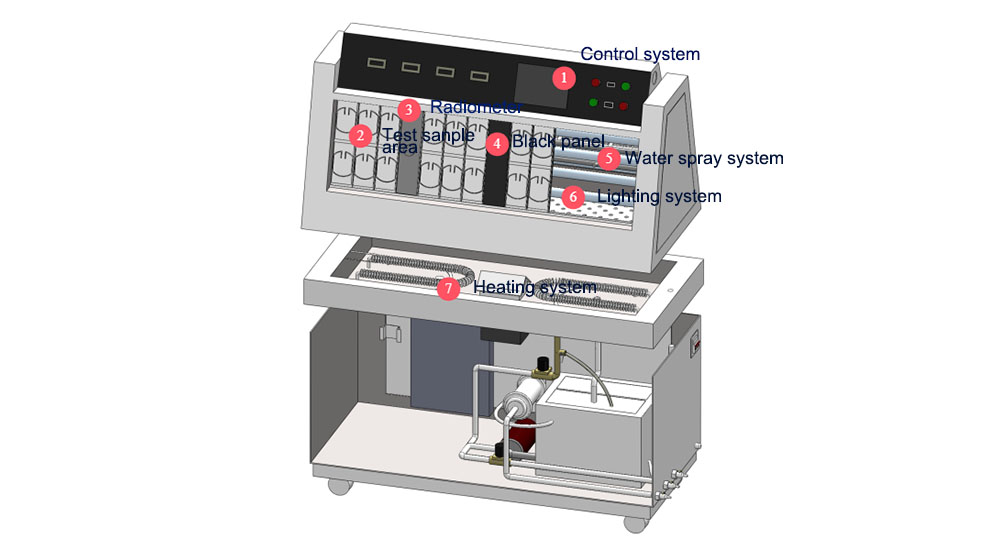

Configuration of UV Accelerated Weathering Chamber

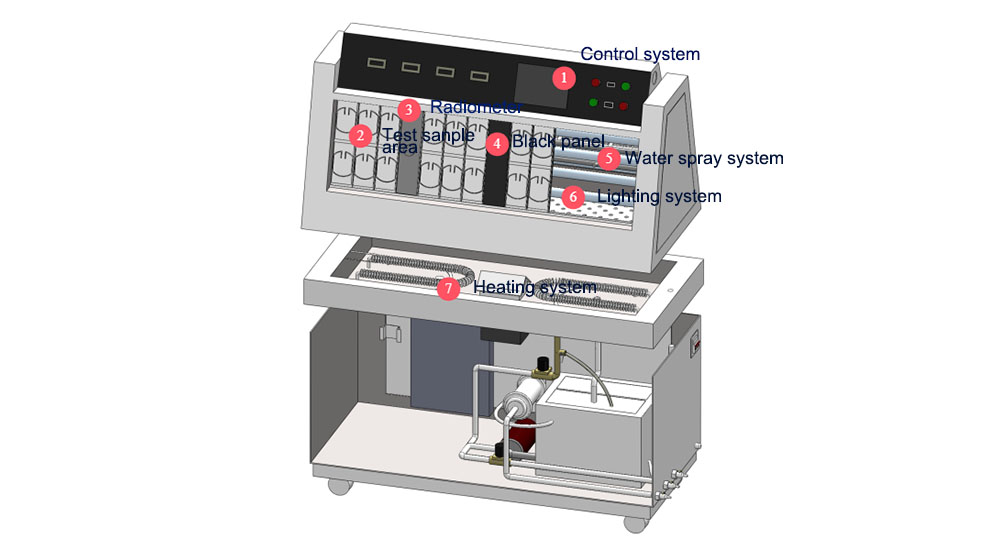

① Control system |

Programmable controller (PLC), which can accurately control the ultraviolet radiation intensity, temperature, humidity, test time and other parameters during the test.

|  |

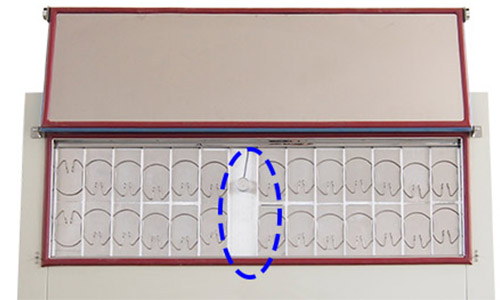

② Test sample area | Each specimen size is 75mm*150mm, can hold 52 pieces of specimens. |  |

③ Radiometer | Mainly used to measure the radiant energy power density of ultraviolet rays. |  |

④ Black panel | Simulate the thermal radiation of the material in the actual use environment. |  |

⑤ Water spray system | Including water tank, water pump, nozzle, water pipe. The tank is used to store water, and the nozzle sprays the water evenly over the test sample, simulating the action of rain or dew. |  |

⑥ Lighting system | UVA-340 lamps and UVB-313 lamps, etc., are divided into two rows, each row of 4 lamps, and maintain a certain distance between the lamps to ensure the uniformity of ultraviolet radiation. |  |

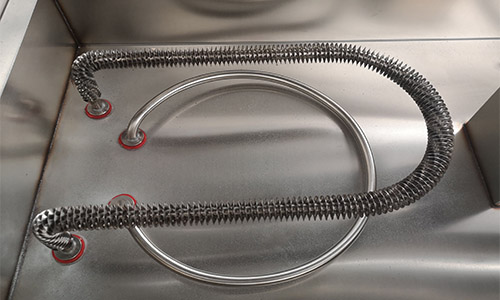

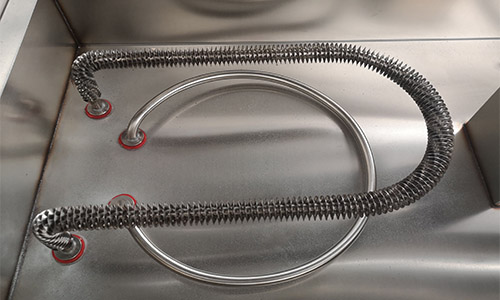

⑦ Heating system | The heating method is the inner tank type heating, the heating speed is fast, and the temperature distribution can be more uniform. |  |

Typical Applications

LIB industry UV accelerated weathering chamber is widely used for:

Plastics and polymer materials

Paints and surface coatings

Rubber and sealing materials

Automotive interior and exterior components

Construction and building materials

Service & Support

Backed by a 3-year warranty, lifelong technical support, and a 24/7 English-speaking service team, LIB industry ensures stable operation throughout long-term weathering tests.

With globally stocked spare parts and professional commissioning support, downtime is minimized and testing continuity is fully protected.

Request Technical Specifications or Quotation

Contact LIB industry for Your UV Accelerated Weathering Testing Solution

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia