Temperature and Humidity Test Chamber Features and Benefits

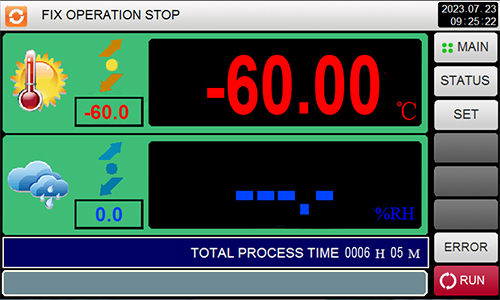

1. The low temperature range is wide, and the temperature can be freely selected from -20°C/-40°C/-60°C/-70°C to +150°C.

2. Humidity range can be selected from 10%-98%RH or 20%-98%RH.

3. The temperature and humidity test chamber can be combined with vibration, low air pressure and other environmental conditions. A variety of comprehensive environments can meet the diverse testing requirements of customers.

4. LIB industry has standard products and customized products for the temperature and humidity test chamber. The delivery time of customized temperature humidity control chamber is fast, and engineers will go to the site for installation and training. The equipment is simple and easy to operate.

Temperature and Humidity Test Chamber Specifications

Model | TH-100 | TH-225 | TH-500 | TH-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

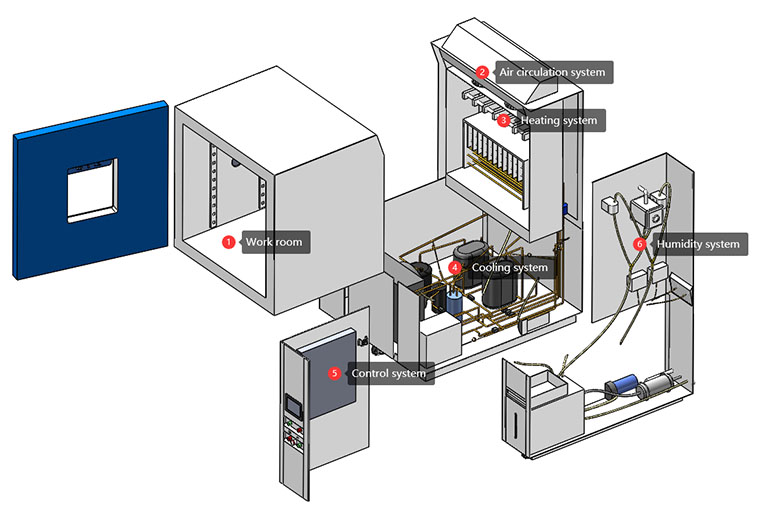

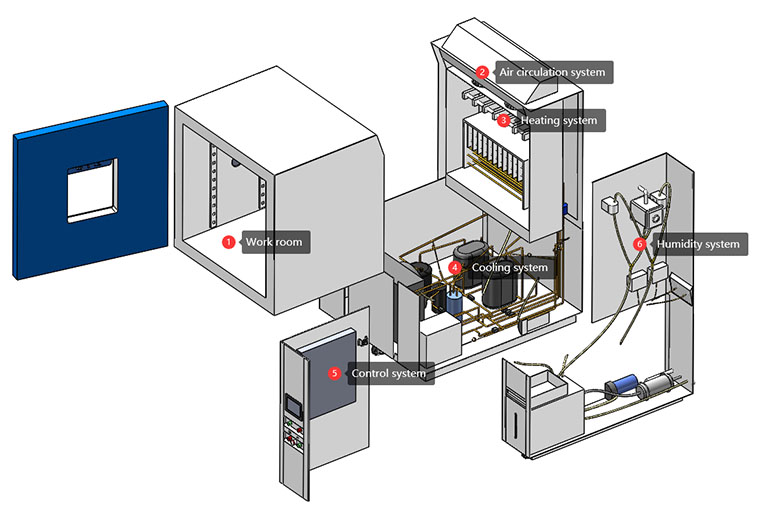

Configuration of Temperature and Humidity Test Chamber

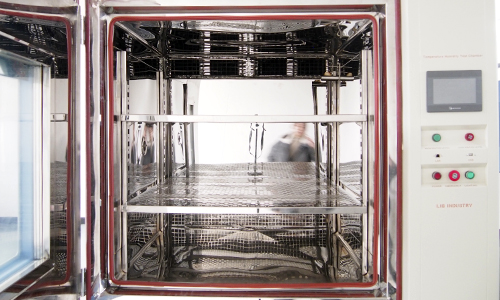

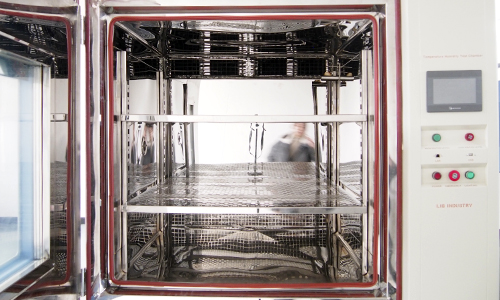

① Workroom |

Equipped with punch chamber sample holder, adjustable height, removable. SUS 304 Mirror stainless steel with good corrosion resistance and thermal conductivity. |  |

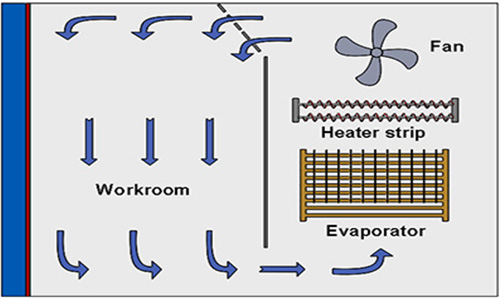

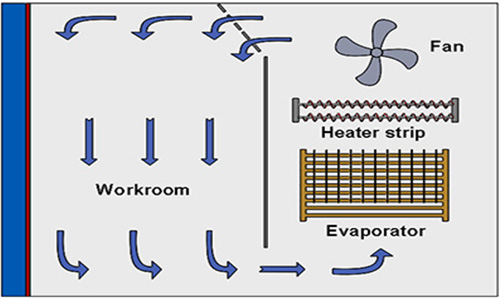

② Air circulation system

| 2,4,6... pcs centrifugal fans, the fan makes the air flow, the motor provides power for the fan. The fan draws air from the return air port and sends it to the workroom through the supply air port. |  |

③ Heating system | High power resistance wire guarantees fast heating rate. Equipped with temperature sensors and other monitoring devices, real-time feedback temperature information. |  |

④ Cooling system | It is mainly composed of a compressor, a condenser, a throttling device (capillary) and an evaporator to form a refrigeration cycle. |  |

⑤ Humidity system | Including humidifier, water tank, water level sensor, steam pipeline, etc. The float water level sensor is used to monitor the water level in the tank and prevent the humidifier from drying out. Steam is transported to the workroom to achieve the addition. |  |

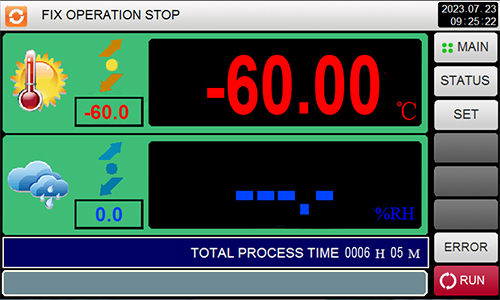

⑥ Control system | PID control, programmable test program, with temperature control, humidity control, fault alarm, data recording and other functions. |  |

A variety of options, there are standard temperature and humidity test chambers, also support custom test chambers, from the door, refrigeration system, controller, language system and other optional accessories to customize the personalized test chambers.