Features and Benefits of MIL STD 810 Dust Chamber

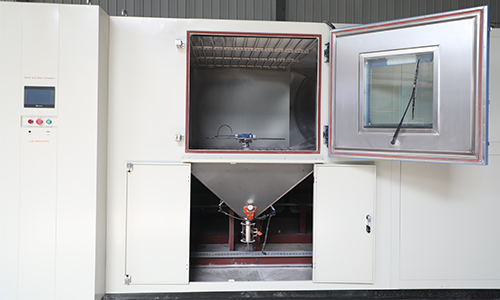

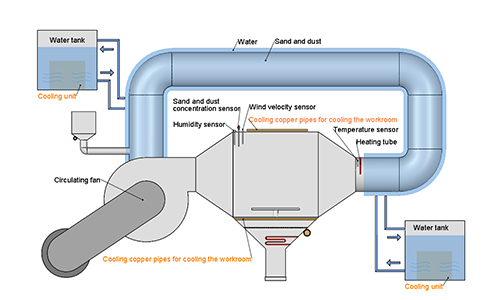

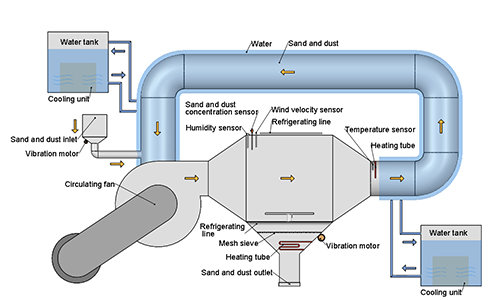

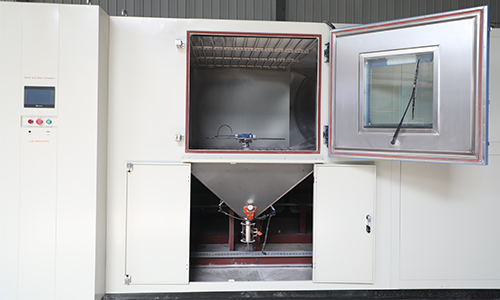

The mil std 810 test chamber is made of SUS304, which can withstand the impact of sand and dust under high wind speed for a long time and wear, ensuring the service life of the equipment.Double rubber sealing, prevent sand and dust leakage.

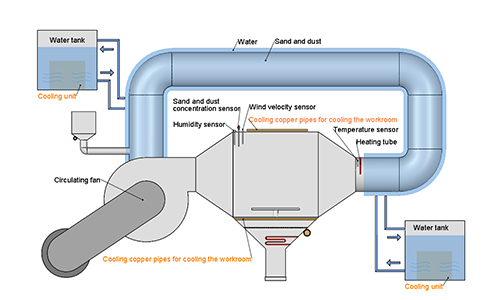

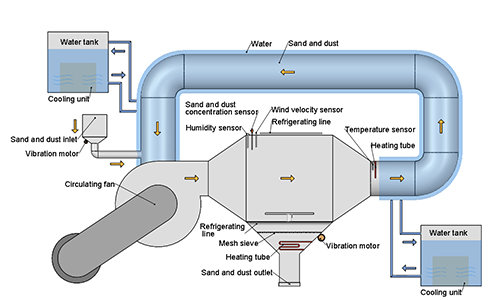

Accurate test parameter control, the workroom is equipped with temperature probe, wind speed probe, concentration probe which ensure accurate data and timely return to the controller.

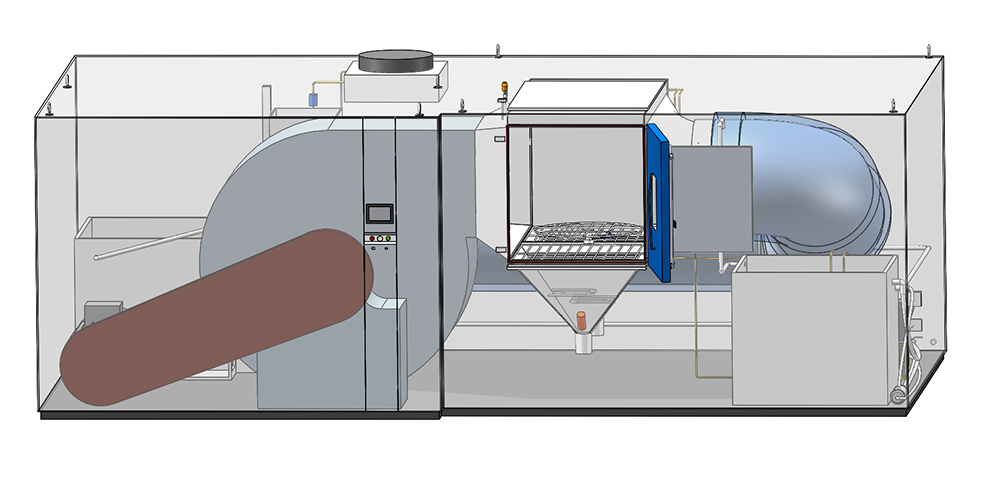

Water circulation cooling system,The sand flying in the high wind speed in the workroom and pipe, and the inner wall of the pipe friction to produce high heat. Three water tanks are arranged outside the pipe for water circulation, and a circle of water surrounds the outer wall of the wind speed pipe to cool it.

Dust circulation:the bottom of the test chamber is a funnel-shaped structure, and the dust falling to the bottom is collected and filtered by the collection port through mesh sieve, and then inhaled and raised by the fan again to realize the repeated recycling of sand and dust.

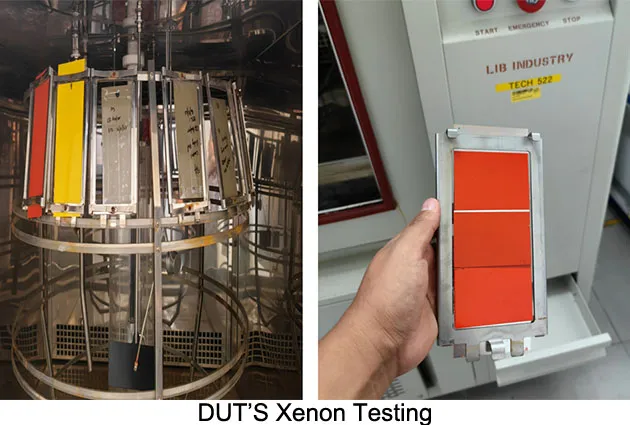

Specifications of MIL STD 810 Dust Chamber

Model | DIM-1000 |

Internal Dimension | 1000*1000*1000mm D*W*H |

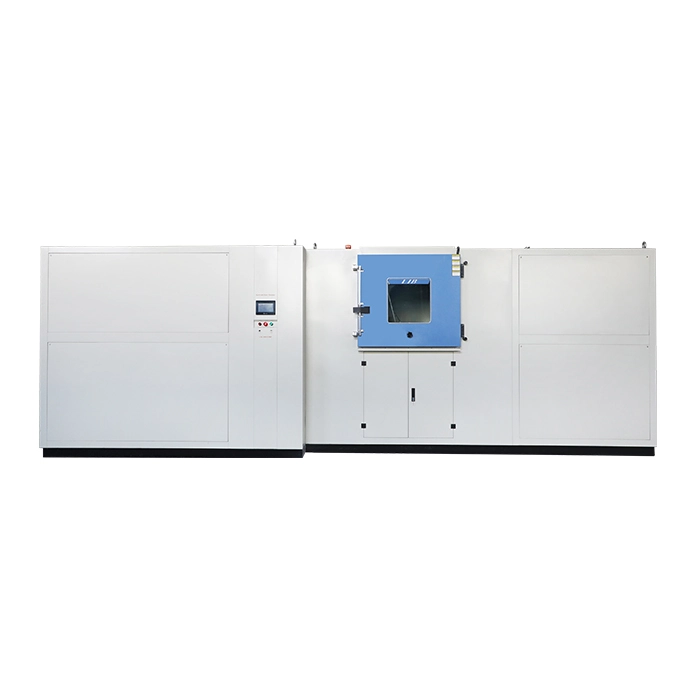

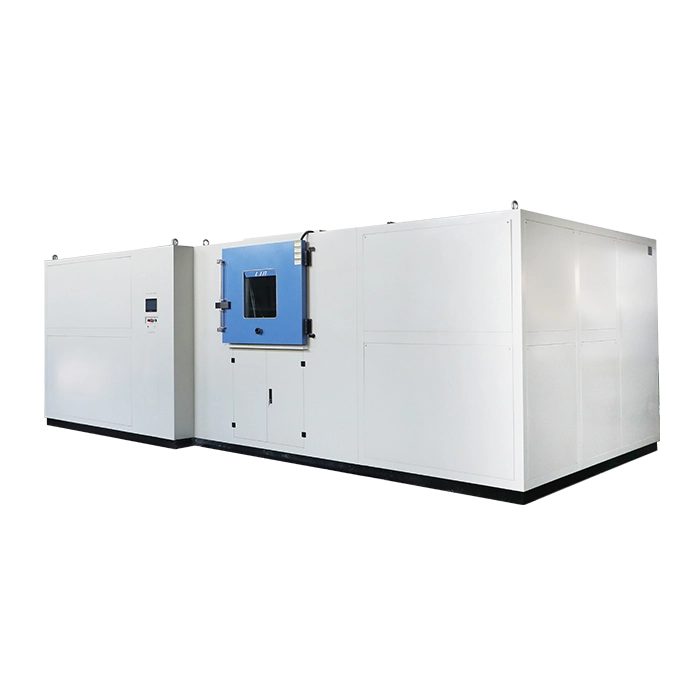

Overall Dimension | 3000*6100*2200mm D*W*H |

Interior Volume | 1000L |

Blowing Dust |

Air velocity | 1.5 -8.9m/s |

Concentration of dust | 10.7±7g/ m³ |

Dust particles | < 150μm |

Blowing sand |

Air velocity | 18.0 -29.0m/s |

Concentration of sand | 0.18+0.2g/m³; 1.1+0.3g/m³; 2.2+0.5g/m³ |

Sand particles | 149μm - 600μm, 600μm - 850μm |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Testing Platform Diameter | 600mm |

Door Lock | Electromagnetic lock |

Testing Platform Speed | 1-7 r.p.m |

Dust Detector | Integrated dust detector |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard | MIL-STD- 810 |

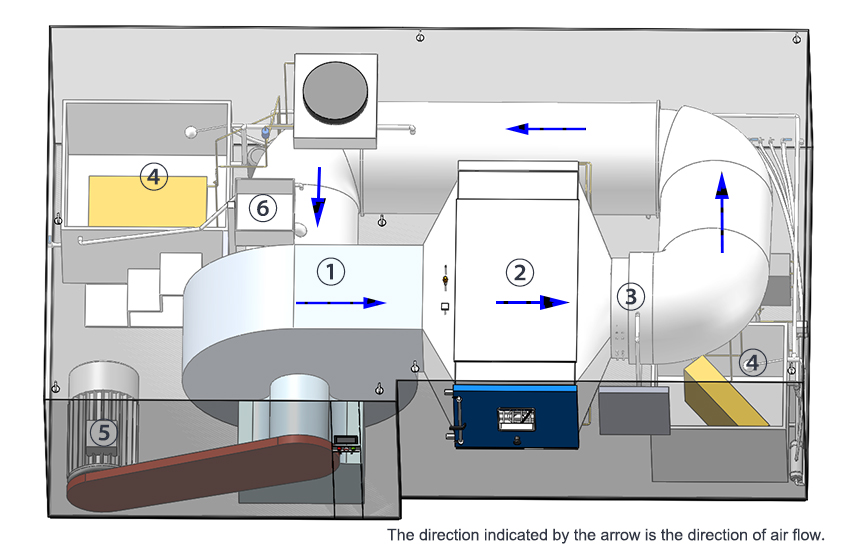

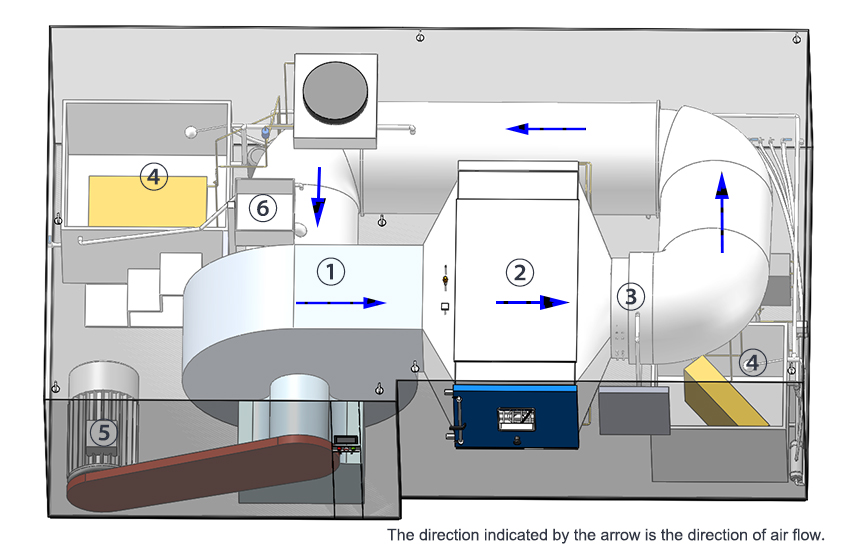

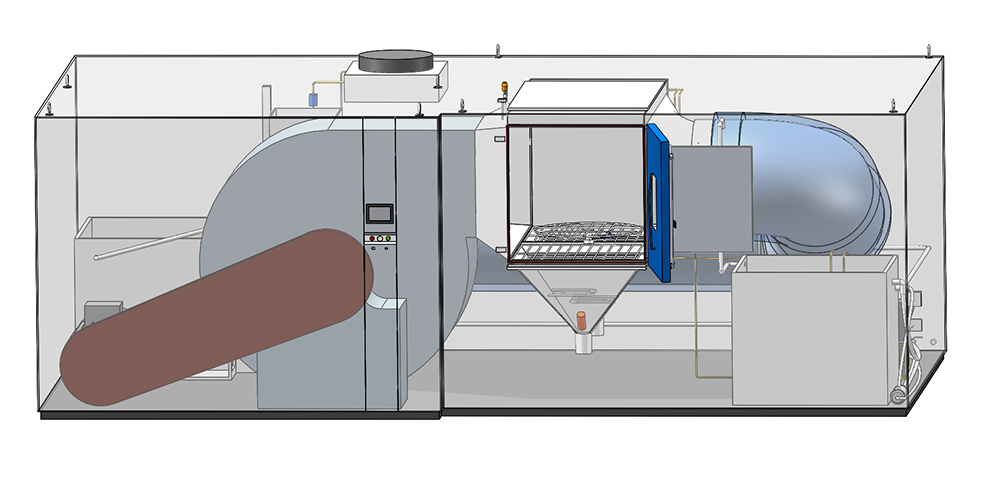

Configuration of MIL STD 810 Dust Chamber

The centrifugal fan① is driven by the pump pulley⑤, and then the bearing chamber drives the fan to rotate, and the sand is blown into the workroom from the left side of the fan.

The dust inlet⑥is equipped with a simple ladder below, which is convenient for the staff to pour the dust, and the vibration motor is equipped to prevent the sand from caking.Dust stepper motor controls dust entry.

There are two funnels under the workroom②, each equipped with heat pipes to keep the dust dry and vibration motors to prevent the dust from clumping

The remaining dust can be removed from the workroom at the dust return port ⑦after the test.

The right side of the workroom is equipped with a temperature probe and heating tube③ to maintain the temperature in the working room

The water tank④ stores water and participates in pipe cooling and water circulation

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia