In today's fast-paced technological world, ensuring the reliability and safety of products under various environmental conditions is no longer optional—it's essential. From electric vehicles (EVs) and consumer electronics to aerospace components and pharmaceuticals, precise environmental testing has become a cornerstone of product development. Among the diverse testing solutions available, battery test chambers and general environmental chambers stand out as two critical yet distinct tools. Understanding their differences, capabilities, and ideal applications is key to making the right investment for your testing needs.

Battery technologies, particularly lithium-ion and advanced energy storage systems, demand rigorous testing under controlled conditions. Battery test chambers are specifically engineered to simulate the environmental stresses batteries may encounter in real-world applications, including temperature fluctuations, high humidity, vibration, and altitude variations.

- Temperature Range & Cycling: Typically -70°C to 150°C, enabling thermal cycling and thermal shock testing critical for evaluating battery durability.

- Advanced Safety Systems: Features such as thermal runaway protection, fire suppression systems, and reinforced containment minimize risk during high-energy testing.

- Precision Monitoring: Real-time measurement of capacity, voltage, current, cycle life, and charge/discharge rates ensures accurate assessment of performance.

- Customizable Racks and Holders: Supports multiple cells or battery packs simultaneously, maintaining uniform environmental conditions.

These capabilities make battery test chambers indispensable for industries like electric vehicles, wearable electronics, and energy storage, where battery efficiency, safety, and lifespan directly impact product success.

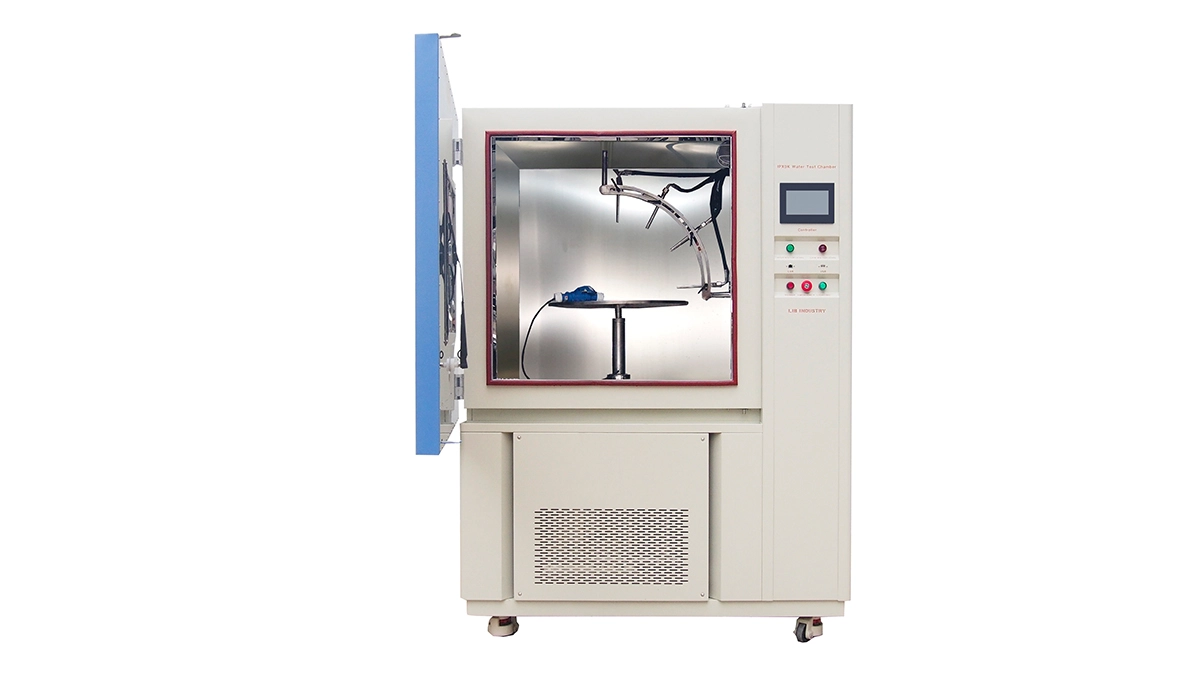

While battery chambers are highly specialized, general environmental chambers provide a flexible solution for testing a wide array of products under controlled conditions. These chambers include temperature chambers, humidity chambers, climate chambers, and thermal cycling chambers, allowing manufacturers to simulate environmental stresses across diverse industries.

- Temperature & Humidity Control: Maintain precise conditions (e.g., -40°C to 150°C; 20–98% RH) to test product stability.

- Adaptable Test Conditions: Support tests such as salt spray, ozone exposure, vibration, and stability screening.

- Safety & Reliability: Equipped with over-pressure vents, backup power systems, and alarms to ensure consistent testing without interruption.

- Industry-Wide Applications: Ideal for aerospace components, pharmaceuticals, consumer electronics, and automotive parts requiring standardized environmental testing.

The adaptability of general environmental chambers allows manufacturers to conduct long-term stability tests, environmental stress screening (ESS), and quality assurance protocols efficiently and cost-effectively.

The choice between battery test chambers and environmental chambers often depends on the testing objectives. In LIB industry, the battery test chamber is essentially a temperature chamber upgraded for high-risk battery applications with explosion-proof features. It also offers a high thermal variation rate, customizable according to testing needs.

| Feature | Battery Test Chamber | General Environmental Chamber |

| Temperature change Range | 10 ℃ / min (average),can be customized | 1~3℃/min |

| Safety Features | Enhanced (explosion-proof design, fire suppression, smoke detection) | Standard (over-pressure venting, backup power) |

Environmental Stress | Thermal shock, vibration, rapid temperature changes | Temperature cycling, humidity, salt fog, ozone |

| Instrumentation | Advanced monitoring for voltage, current, cycle life | General environmental sensors |

| Application Focus | EVs, electronics, energy storage | Aerospace, pharmaceuticals, consumer goods |

Insight: LIB industry's battery test chambers combine high-speed thermal control with robust safety measures, excelling in precision-critical battery testing, whereas general environmental chambers remain versatile tools suitable for a broad spectrum of products and conditions.

Safety remains the top priority, especially for high-energy battery testing. Battery test chambers integrate multiple layers of protection:

- Automatic Shutdown Systems to prevent catastrophic failures.

- Fire Suppression and Containment to mitigate hazards during thermal runaway.

- Real-Time Monitoring to detect voltage, current, and temperature anomalies instantly.

General environmental chambers prioritize stable and safe testing across a wide range of products:

- Backup Power Systems ensure continuous operation during outages.

- Integrated Alarms alert operators to deviations from set parameters.The difference lies in the risk profile—battery chambers are built for high-energy, potentially volatile testing, while environmental chambers focus on consistency and adaptability.

Critical for industries where energy storage performance is paramount:

o Automotive: EV battery packs undergo thermal cycling and discharge testing to ensure safety.

o Consumer Electronics: Smartphones, laptops, and wearables rely on accurate charge/discharge cycles and thermal stability.

o Energy Storage: Grid-scale battery systems require long-term reliability validation.

Serve industries with broader environmental testing requirements:o Aerospace: Components face altitude, temperature, and humidity variations.o Pharmaceuticals: Drug packaging and formulations undergo stability and shelf-life testing. Consumer Goods & Electronics: Products must withstand everyday environmental stresses.

Selecting the right chamber requires careful evaluation of test objectives, precision requirements, safety considerations, and budget.

1. Precision & Instrumentation: Battery testing demands highly accurate voltage, current, and thermal measurements.

2. Safety Requirements: High-energy tests need advanced containment and fire suppression.

3. Environmental Versatility: General product testing benefits from wide-ranging temperature and humidity control.

4. Customizability: Both test chamber types can be tailored—racks, sensors, and software profiles—depending on the product.

5. Industry Standards Compliance: Ensure compliance with IEC, ISO, UN 38.3, or MIL-STD-810 standards as relevant.

Selecting the right testing chamber can directly impact product safety, performance, and regulatory compliance. LIB industry offers state-of-the-art battery test chambers and environmental chambers, delivering:

- Fast Delivery: 7–15 days from order to shipment.

- Comprehensive Support: Installation, calibration, and operator training.

- Global Service Points: Rapid on-site assistance and 1–3 hour technical response.

- Custom Engineering: Solutions tailored to your product size, test type, and industry standards.

Ensure your products meet the highest standards—contact LIB industry today to discuss your battery or environmental testing needs.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia