In industries such as textiles, plastics, coatings, and printing, color fading and material degradation due to sunlight exposure present ongoing challenges. For manufacturers, maintaining vibrant colors, ensuring material longevity, and complying with international standards are crucial for customer satisfaction and brand reputation.

Accelerated testing provides a reliable method to predict material performance before real-world exposure. The Xenon Light Fastness Test Chamber simulates sunlight and environmental conditions in a controlled laboratory setting, providing precise insights into material durability. By leveraging advanced Xenon arc technology, manufacturers can anticipate fading, optimize formulations, and validate the performance of their products under real-life conditions.

Accelerated testing provides a reliable method to predict material performance before real-world exposure. The Xenon Light Fastness Test Chamber simulates sunlight and environmental conditions in a controlled laboratory setting, providing precise insights into material durability. By leveraging advanced Xenon arc technology, manufacturers can anticipate fading, optimize formulations, and validate the performance of their products under real-life conditions.

Customer Feedback: One of our clients in India shared that after using our Xenon testing instruments, they found the quality comparable to top international brands while being more competitively priced. Their 20+ years of marketing experience confirmed the reliability and value of our solutions, giving them confidence in adopting our chambers for material testing.

Reliable testing starts with adhering to internationally recognized standards. The following standards are critical for Xenon light fastness testing:

ISO 105-B02 (Textiles): Specifies procedures for testing the color fastness of textiles using Xenon arc lamps. It defines exposure times, light intensity, and humidity conditions to produce reproducible results for fabrics, dyes, and printed textiles.

ASTM G155 (Plastics and Coatings): Provides guidance for operating Xenon arc light apparatus for non-metallic materials, including black panel temperature, light spectrum, and moisture cycling. It is widely used for plastics, paints, and coatings to predict outdoor durability.

EN ISO 4892-2 (Plastics): European standard for plastics, outlining Xenon arc lamp exposure for accelerated aging. It emphasizes realistic simulation of natural sunlight and environmental conditions.

ISO 2836 / ISO 105-B (Printing and Packaging): For inks, packaging films, and printed substrates, ensuring color durability and fading resistance under standardized light exposure.

By following these standards, manufacturers can obtain scientifically accurate and reproducible results, enabling better material selection, formulation optimization, and product design.

The Xenon Light Fastness Test Chamber is engineered to meet the rigorous requirements of ISO, ASTM, and EN standards. It supports a wide range of materials, including textiles, plastics, coatings, printed materials, and automotive components.

1. Precision Light Simulation

Xenon arc lamps cover UVA, UVB, and visible light wavelengths to closely mimic natural sunlight.

Adjustable light intensity ensures accurate exposure according to standard specifications (e.g., ISO 105-B02: 550 W/m²).

High-precision radiometer guarantees stable and reliable light intensity measurement, ensuring accurate irradiation for all tests.

Optional light filters allow precise selection of specific wavelengths to simulate conditions like sunlight through window glass, improving data reliability.

2. Temperature and Humidity Control

Blackboard temperature is precisely maintained between 35–85°C (±2°C) to replicate real solar heat exposure.

Humidity adjustable from 30–98% RH (±2.5%) with alternating dry/wet cycles or spray water cycles to simulate environmental moisture.

Programmable test cycles enable fully automated transitions of light, temperature, and humidity conditions.

Integrated black panel effectively measures specimen aging and durability, providing highly reproducible results.

3. Workroom and Construction

SUS304 mirror stainless steel chamber ensures durability, corrosion resistance, and long-term reliability.

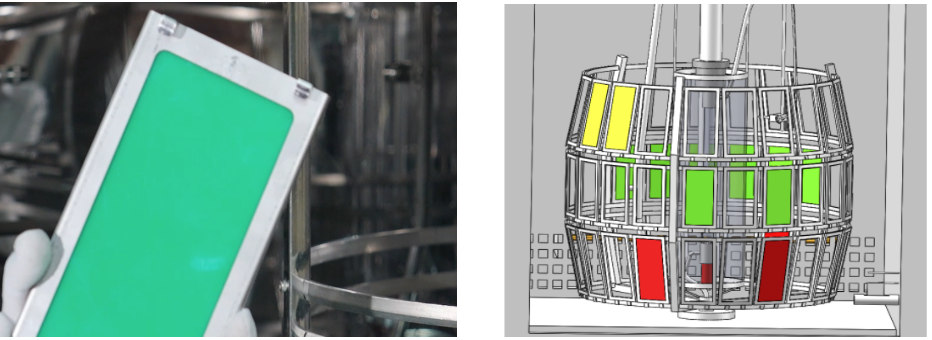

Rotating sample holder is stable, easy to install, and compatible with various test pieces including leather, coatings, and fabrics.

Spray nozzles operate efficiently to accelerate realistic aging while supporting water conservation goals.

4. Sample Versatility and Uniform Exposure

Rotating sample holder accommodates up to 42 specimens simultaneously, ensuring uniform light exposure and water spray across all surfaces.

Supports a wide range of samples: textiles, plastics, coatings, printed materials, and automotive components.

Rotating holder ensures consistent irradiance distribution and reliable, repeatable test data.

|

|

| Workroom | Hanging specimen |

5. Optional Coating Testing

Dedicated trays allow simultaneous testing of multiple coatings or formulations.

Moisture cycling combined with light exposure evaluates UV, heat, and humidity resistance.

Observations can include surface cracking, blistering, discoloration, or delamination for actionable formulation improvement.

6. Intelligent Control and Data Management

PID programmable color touchscreen allows easy setup, real-time monitoring of temperature, humidity, and light intensity.

Up to 120 programs with 100 segments each can be configured to meet different standards and material types.

Multi-language interface, Ethernet/Wi-Fi connectivity, and PC link enable remote monitoring, centralized management, and real-time data collection for traceability.

7. Efficiency, Maintenance, and Mobility

Long-life Xenon lamps (1,600 hours) reduce maintenance and operational costs.

Modular design simplifies replacement of lamps, fans, and sensors.

Automatic water inlet and closed-loop water circulation with filtration supports water recycling, conserving resources while maintaining consistent spray quality.

Four adjustable casters allow easy movement and stable placement on uneven lab floors.

|

|

xenon lamp and filters

This combination of advanced features ensures accurate, reproducible, and standard-compliant testing while optimizing efficiency, environmental sustainability, and ease of operation.

The Xenon arc chamber is engineered to meet the rigorous requirements of ISO, ASTM, and EN standards. It supports a wide range of materials, including textiles, plastics, coatings, printed materials, and automotive components.

The Xenon Light Fastness Test Chamber replicates sunlight-induced aging with high precision.

Step 1: Sample Preparation

Textiles: Cut into standard-sized swatches, mounted according to ISO 105-B02 guidelines.

Plastics/Coatings: Cleaned and fixed on trays to ensure uniform exposure.

Coatings: Multiple layers, colors, or formulations can be tested simultaneously.

Step 2: Sample Installation

Samples evenly spaced within the chamber to maintain consistent distance from lamps.

Optional fixtures for multi-layer coatings or large automotive parts.

Step 3: Setting Test Conditions

Light Intensity: Adjusted to standard-specified levels (e.g., 550 W/m²).

Temperature: Black panel temperature typically set between 50°C–65°C.

Humidity: 30%–80% RH, with optional wet/dry cycles simulating rain or condensation.

Cycles: Dry-light, wet-light, or mixed cycles to mimic natural environmental fluctuations.

|

|

| Control system | Rain spray system |

Step 4: Running the Test

Automated chamber cycles through programmed light, temperature, and humidity sequences.

Real-time monitoring of all environmental parameters ensures accurate simulation.

Step 5: Optional Coating Tests

Evaluate multiple coatings simultaneously for color change, surface cracking, blistering, or delamination.

Mid-test observations and photos can track progressive changes for detailed analysis.

Step 6: Data Collection and Analysis

Post-test, samples are assessed using spectrophotometers or visual grading.

Color difference (ΔE) and coating degradation metrics quantify fading and material aging.

Data supports material selection, formulation adjustments, and quality control.

Through these procedures, the Xenon Light Fastness Test Chamber provides accurate, reproducible, and standard-compliant testing results for a wide range of materials and coatings.

These capabilities allow manufacturers to anticipate real-world performance and optimize product design before market launch.

Model

XL-S-750

Internal Dimension (mm)

950*950*850 mm

Overall Dimension (mm)

1300*1420*1800 mm

Sample holder

Adjustable speed, 1r /min

Chamber Type

Rotating Holder

Irradiation Source

1 piece of 4500w water-cooled xenon arc lamp with inner quartz and outer borosilicate filter

Irradiance Range

150 W/㎡

Bandwidth Measurement

300~400 nm

Chamber Temperature Range

-40~ 100 ℃ ±2 ℃

Black Panel Temperature

BPT 35 ~ 85 ℃ ±2 ℃

Humidity Range

30 % ~ 98 % RH

Water Spray Cycle

1~9999 H 59 M (Adjustable)

Controller

Programmable color LCD touch screen controller

Radiometer

UV Radiometer, Tolerance: ±5 %

Textiles & Dyes: Ensures color fastness for fabrics and prints according to ISO 105-B02, reducing returns due to fading.

Plastics & Coatings: ASTM G155 or EN ISO 4892-2 testing predicts yellowing, cracking, or warping, ensuring long-term durability.

Printing & Packaging Materials: Maintains ink vibrancy and print quality for labels, films, and packaging exposed to sunlight.

Automotive Components: Interior and exterior parts tested for UV resistance, color stability, and coating durability.

The Xenon Light Fastness Test Chamber delivers accurate, repeatable, and standard-compliant testing for a wide range of materials. Whether for textiles, plastics, coatings, printed materials, or automotive components, integrating a Xenon Light Fastness Test Chamber into your testing workflow ensures products remain vibrant, durable, and market-ready.

Enhance your product testing with LIB industry today! We also offer UV Test Chambers for additional light aging simulations. Enjoy a 3-year warranty, lifelong technical support, and responsive English-speaking service—ensuring reliable, worry-free operation throughout the equipment lifecycle.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia