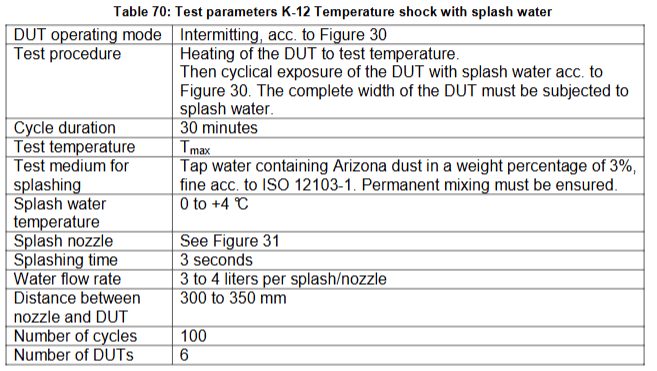

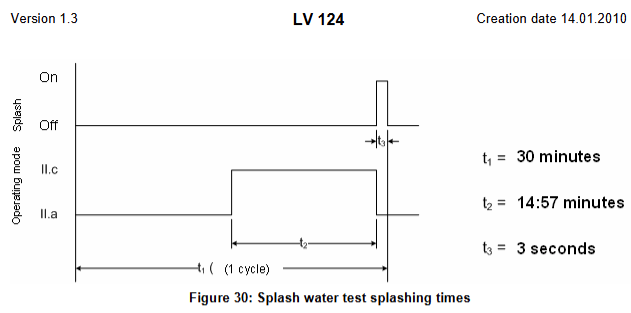

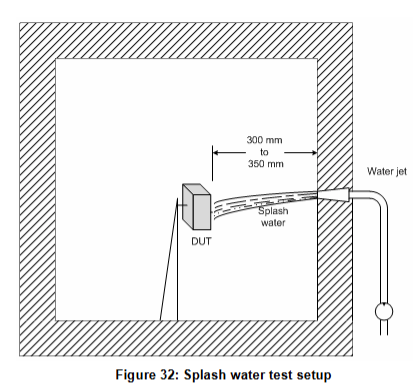

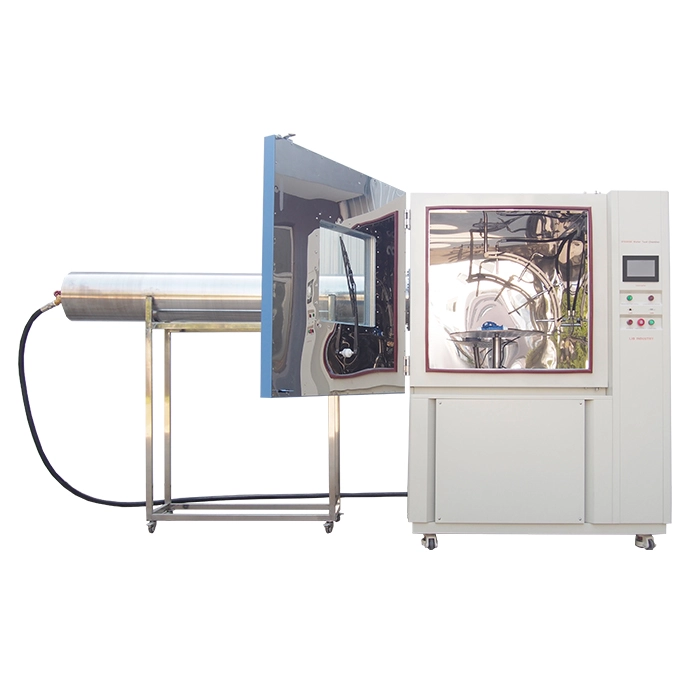

The LV124 K-12 Temperature Shock and Splash Water Test Equipment simulates rapid temperature changes from ambient to +150°C, combined with controlled splash water exposure at 0–4°C, It simulates rapid temperature changes and splash water exposure, reproducing the extreme conditions components face in real vehicles.

The equipment applies controlled bursts of cold water at regular intervals, simulating the rapid thermal shock and moisture conditions specified by LV124 K-12. This method ensures repeatable and precise stress conditions while maintaining the workroom at ambient or set temperatures.The test piece supports powered testing.

This testing system is used to validate the durability, reliability, and performance of critical automotive components, including:

Engine Control Units (ECUs)

Sensors and actuators

Power electronics modules

Connectors and wiring harnesses

Standards & Compliance:LV124 K-12 ,ISO 16750 (Environmental conditions for electrical/electronic equipment),OEM-specific automotive lab requirements

Standard models: T-1000A and more customized models based on your testing needs

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia