Photovoltaic power plant construction is extending from inland to coastal, island and other complex environments. Metal frame corrosion, junction chamber aging and other problems occur frequently. Traditional salt spray chamber testing usually requires cutting photovoltaic panel samples, and the test results are biased from actual use.

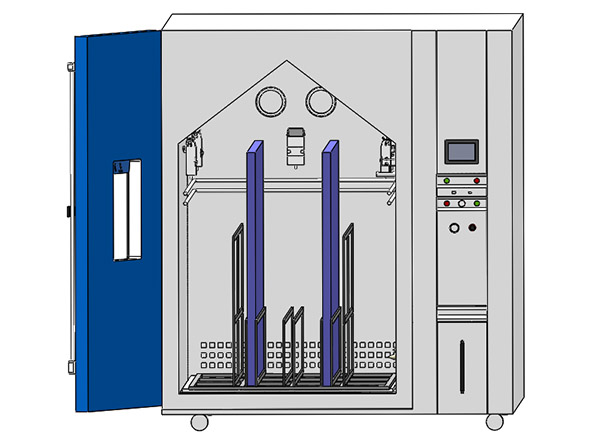

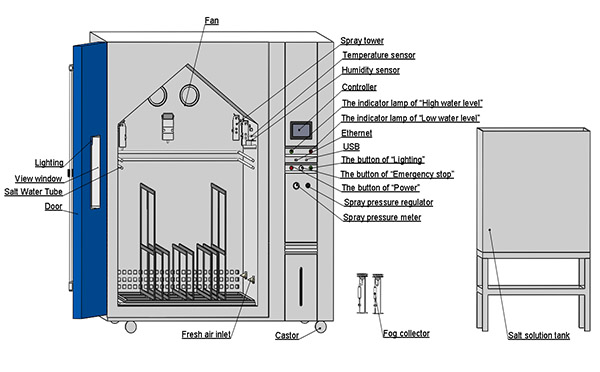

In response to this, LIB has specially developed a walk-in salt spray test chamber that directly simulates the real environment of a complete PV panel.

LIB conventional salt spray chamber capacity from 110L, 320L... Up to 1600L. Conventional salt spray test chamber is not only unable to meet the size of the salt spray test of the whole PV panel, but also very limited in the placement of PV panels. This leads to two problems:

1. Edge distortion: the edge of the sample after cutting is exposed, and the salt spray corrosion speed is abnormally accelerated, which cannot reflect the real situation;

2. The overall failure is difficult to find: key parts such as junction chambers and border connections are damaged, and hidden dangers are detected.

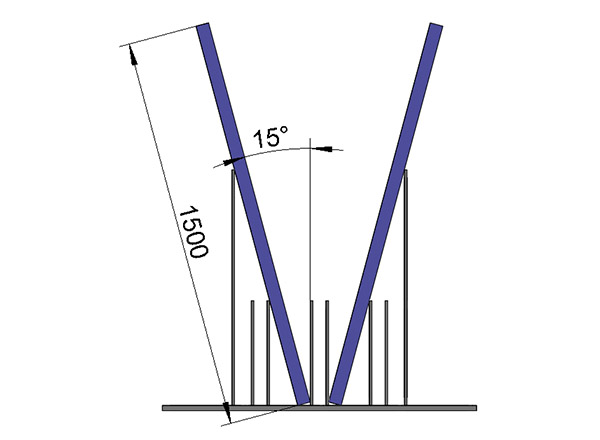

LIB's walk-in salt spray test chamber allows the operator to directly walk in and install the entire photovoltaic panel, and can also adjust the tilt Angle to simulate different installation scenarios such as roof and ground. LIB sets the number of spray towers according to the size of the workroom to ensure that the salt spray is evenly sprayed in every part of the workroom.

The air circulation system ensures uniform distribution of ambient parameters in the workroom

Customized sample rack, photovoltaic panel can be fixed, adjustable Angle

In addition to the salt spray, the temperature and humidity are controllable, which greatly expands the possibility of salt spray test

Name | Salt Spray Chamber |

Temperature Range | +10 ℃ ~ +90 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 30% ~ 98% RH |

Humidity Deviation | + 2%, - 3% |

Salt Fog Deposition | 1~2ml / 80cm2 · h |

Cooling system | Mechanical compression refrigeration system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Water supply system | Water purification system |

Air Preheating | Saturated air barrel (31Liter) |

Spraying System | Atomizer tower and Spray nozzles |

Salt Fog Collected | Fog collector and fog measure cylinder |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Air Circulation | Centrifugal wind fan |

| |

If you have similar needs, please consult LIB, LIB has rich experience in custom test chambers, providing one-stop services from design, transportation, installation and training.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia