Rubber, elastomers, and other non-metallic materials are increasingly exposed to harsh environments where ozone can cause premature cracking, reduced durability, and unexpected failures. In industries such as automotive, electronics, and industrial manufacturing, these failures can lead to costly recalls, product downtime, and reputational risks.

ASTM D1149 is the internationally recognized standard for evaluating how materials respond to ozone exposure under controlled conditions. It provides manufacturers with reliable, repeatable, and actionable insights into material performance before products ever leave the factory.

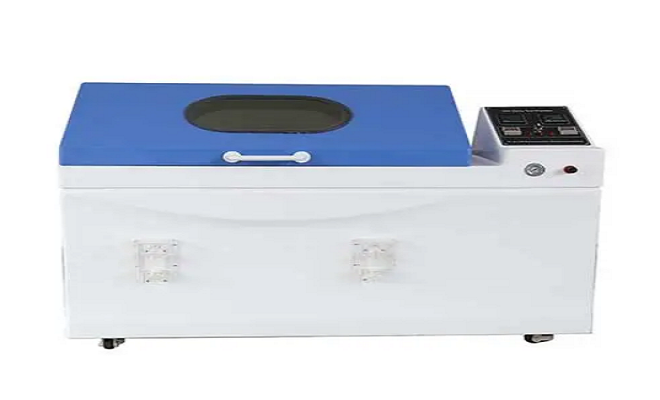

LIB industry Ozone Test Chamber is designed to meet and exceed the requirements of ASTM D1149, delivering precise control over ozone concentration, temperature, mechanical stress, and humidity. With this chamber, manufacturers can simulate real-world conditions, identify potential weaknesses early, and enhance product reliability. In short, it’s not just a testing chamber—it’s a strategic tool for quality assurance and competitive advantage.

ASTM D1149 sets the benchmark for evaluating the susceptibility of rubber and elastomeric materials to ozone-induced cracking. By following this standard, manufacturers can predict long-term material performance, optimize formulations, and avoid costly product failures. This standard transforms ozone testing from a guesswork process into a precise, actionable evaluation method.

ASTM D1149 defines rigorous testing parameters to ensure reliability:

Ozone Concentration: Maintained between 50–100 pphm, adjustable depending on material sensitivity.

Temperature: Typically set around 40°C ± 2°C for consistent aging.

Mechanical Stress: Samples are stretched under controlled tension, usually 20–50%, sometimes up to 80%, replicating real-world stress conditions.

Exposure Duration: From hours to several days, depending on testing objectives and material behavior.

ASTM D1149 is widely applied to automotive seals, cable jackets, gaskets, hoses, and other elastomeric components. By adhering to this standard, manufacturers can confidently release products with verified durability, performance, and safety.

LIB industry integrates static and dynamic sample holders to ensure comprehensive testing. With 360° rotation and 5–80% adjustable stretching, each sample is evenly exposed to ozone under realistic stress conditions.

Customer Benefit: Simulates real operational stress, providing reliable, actionable insights into material performance and minimizing the risk of field failures.

Equipped with high-accuracy ozone sensors capable of 1–1000 pphm detection, the chamber maintains precise ozone concentrations throughout the test.

Customer Benefit: Reliable, repeatable data that manufacturers can trust for quality assurance and material development.

The PID touchscreen controller enables precise management of ozone concentration, temperature, and humidity, with features including:

Real-time monitoring and logging.

Remote access and scheduling via Ethernet.

Multi-program support with up to 120 programs and 100 segments each.

Automatic alarms for deviations or abnormal conditions.

Customer Benefit: Streamlined operation reduces manual intervention, increases test efficiency, and ensures data consistency.

The inner chamber uses SUS304 stainless steel, providing long-term resistance to ozone corrosion.

Customer Benefit: Reliable performance for repeated tests, lower maintenance costs, and a longer equipment lifespan.

Activated carbon filtration neutralizes residual ozone.

Electromagnetic door locks prevent accidental openings while maintaining airtight seals.

Automatic alarms notify operators of abnormal conditions.

Customer Benefit: Safe, compliant, and energy-efficient operation, giving peace of mind to lab managers and engineers.

| ASTM D1149 Requirement | LIB industry Feature | Customer Benefit |

|---|---|---|

| Ozone Concentration Control | 1–1000 pphm sensor, real-time monitoring | Accurate, reliable testing results |

| Sample under tension | 5–80% adjustable clamps, 360° rotation | Simulates real-world stress, prevents failures |

| Temperature & Humidity | Precise control 10–100°C, 30–98% RH | Predictable material behavior |

| Safety & Environmental | Carbon filter exhaust, electromagnetic door lock | Safe, compliant, and energy-efficient |

ASTM D1149 is the gold standard for ozone resistance testing, and LIB industry Ozone Test Chamber delivers precise, reliable, and safe testing that fully meets these requirements. By replicating real-world stress, tension, and ozone exposure, manufacturers can reduce failures, extend material longevity, and strengthen product credibility.

Beyond ozone: LIB industry also provides Noxious Gas Test Chambers, capable of handling single-gas and multi-gas scenarios, enabling comprehensive material and component evaluations under corrosive and industrial gas conditions.

Peace of mind guaranteed: All LIB equipment comes with a 3-year warranty, lifelong technical support, and responsive English-speaking service, ensuring reliable, worry-free operation throughout the equipment lifecycle.

Contact LIB industry today to explore our Ozone Test Chambers, request a custom solution, and elevate your material testing capabilities to the highest international standards.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia