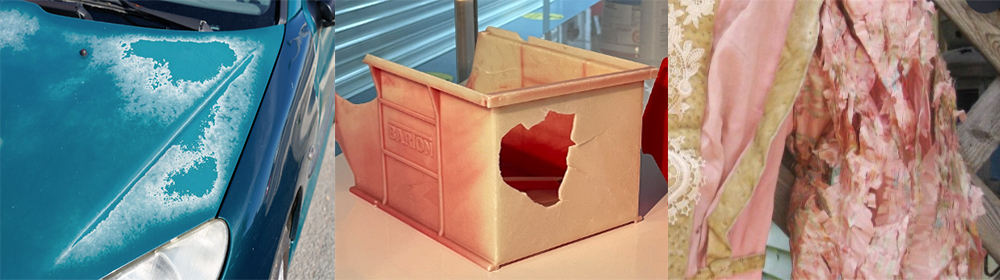

When manufacturers face the challenge of predicting how materials age under sunlight, heat, and moisture, the stakes are high. Coatings fade, plastics crack, and textiles weaken if durability is not carefully tested before release. The critical question becomes: how can you simulate years of outdoor exposure in weeks, with precision and confidence?

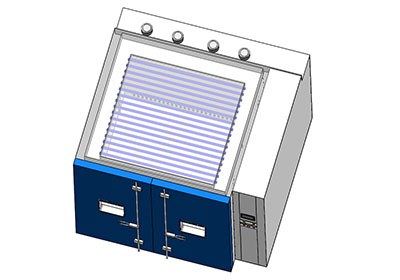

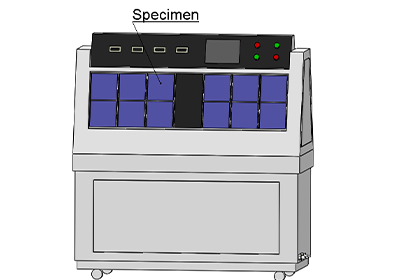

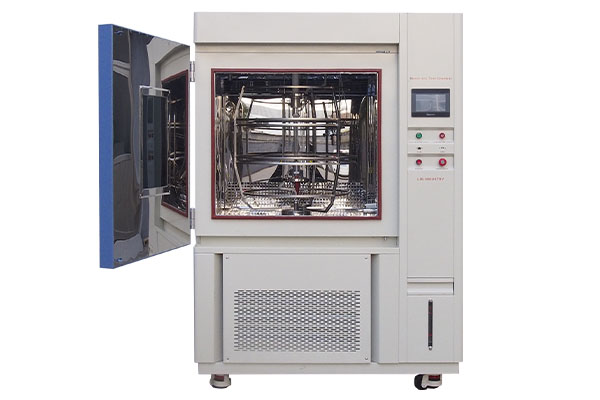

LIB industry provides the solution with its UV accelerated weathering chamber , engineered to deliver accurate, repeatable, and internationally recognized results. From R&D laboratories to quality control teams, LIB industry ensures that every customer can confidently verify UV stability, light fastness, and long-term weathering resistance.

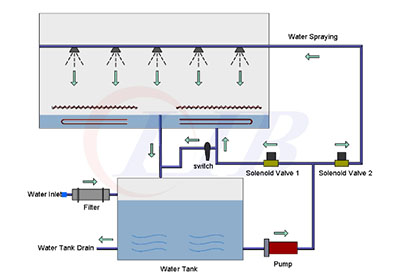

The UV accelerated weathering chamber replicates years of sunlight and rainfall in controlled conditions. Imported QUV lamps (UVA-340, UVB-313) provide irradiation in the 290–400 nm range, with a lifespan up to 5000 hours. The black panel temperature (BPT) control ensures 35–85 °C ±2 °C, replicating solar heating, while a spray system simulates rainfall and condensation cycles.

|  |

Samples are mounted on aluminum racks or customized holders for irregular materials. Built-in radiometers continuously monitor UV irradiance, guaranteeing compliance with ASTM G154, ASTM G151, ISO 4892-3, and ISO 11341 standards.

With PID-controlled touchscreen interfaces, multilingual programming, and Ethernet/USB data export, LIB industry offers both precision and ease of operation.

LIB industry’s UV light fastness test chamber https://www.libtest.com/products/uv-light-fastness-test-chamber.html excels in testing plastics, coatings, textiles, and packaging.

Key Specifications (Model UV-SI-260):

· Internal Dimension (mm): 450 × 1170 × 500

· Irradiation Source: Fluorescent UV lamps (8 × 40 W)

· Temperature Range: Ambient to 90 °C ±2 °C

· BPT Control: 35–80 °C

· Humidity Range: ≥95% RH

· Irradiance Control: 0.3–20 W/m²

· Spray System: 10 nozzles, ~0.3 L/min, automatic filtration

· Controller: Programmable LCD touchscreen, 120 programs, Ethernet/USB

This design ensures reliable, reproducible, and globally accepted results, meeting the highest testing demands for accelerated aging and UV light fastness test chamber applications.

LIB industry recognizes that every customer requires flexibility. That’s why the UV accelerated weathering chamber can be fully customized.

Customization Option | Details Available | Image |

Chamber Size | Bench-top, standard, or walk-in large formats |  |

Lamp Type | UVA-340, UVB-313, UVB-351 |  |

Controller | Touchscreen, PC-linked, remote monitoring |  |

Sample Holders | Standard racks, rotating holders, 3D fixtures |  |

Additional Features | Water-cooled systems, automatic refilling, enhanced safety |  |

With these options, customers can design chambers tailored for their exact material and testing requirements.

While UV accelerated weathering chambers focus on ultraviolet-driven degradation, LIB industry also offers Xenon arc weathering chambers for full-spectrum sunlight simulation (280–800 nm).

Key Specifications :

Specification | Details |

Irradiation Source | 4500 W water-cooled xenon arc lamp |

Spectrum Range | 280–800 nm (UV, visible, IR) |

Irradiance Range | 35–150 W/m² (adjustable) |

Black Panel Temperature (BPT) | 35–85 °C ±2 °C |

Chamber Temperature Range | Ambient to 100 °C ±2 °C |

Humidity Range | 50%–98% RH |

Sample Holder | Rotating holder, adjustable speed 1 r/min |

Spray & Condensation Cycles | 1–9999 hours programmable |

Controller | Color LCD touchscreen, PC/Ethernet/USB link |

Water Supply | Automatic refilling, closed-loop water recovery (up to 80% saving) |

Standards Supported | ASTM G151, ASTM G155, ISO 11341, ISO 4892-2, SAE J2527 |

| |

These xenon test chamber solutions complement UV chambers, allowing you to choose between UV-focused degradation studies or complete sunlight simulation for real-world durability testing.

LIB industry delivers more than just reliable equipment:

16+ years of expertise in accelerated weathering testing.

Stock availability for fast delivery.

Custom designs to fit any laboratory or industrial need.

Global service network with 3-year warranty, lifetime maintenance, on-site repair, and free training support.

Fast response—receive your exclusive quotation and testing plan within 1–3 hours.

Don’t let untested materials lead to costly failures. Partner with LIB industry for the most precise UV accelerated weathering chamber available.

Contact LIB industry today inquiry@libtestchamber.com with your testing requirements, and within 1–3 hours our team will deliver your tailored quotation and testing plan.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia