Micro amounts of harmful atmospheric gases such as hydrogen sulfide (H2S), sulfur dioxide (SO2), nitrogen dioxide (NO2), and chlorine (Cl2) can cause significant chemical corrosion on precision electronics and metallic components. For example, H2S rapidly tarnishes silver contacts, while SO2 and Cl2 accelerate pitting on nickel and copper surfaces. Left untested, these reactions can lead to early failures in PCBs, connectors, and electroplated layers.

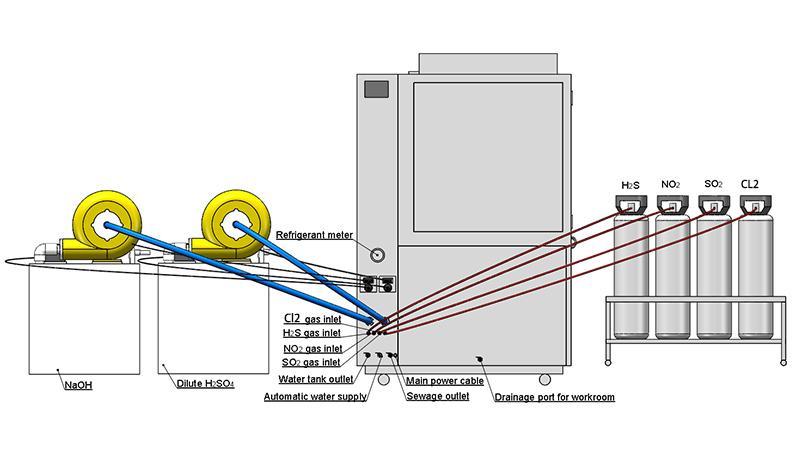

By increasing environmental stress—gas concentration, temperature, and humidity—accelerated corrosion testing compresses years of natural exposure into a controlled laboratory timeframe. LIB industry’s Noxious Gas Test Chamber enables engineers to evaluate material longevity and product reliability under reproducible conditions, providing actionable insights during the R&D phase.

|

|

Gas Dynamics in Accelerated Corrosion Testing:

LIB industry’s chamber precisely controls the mixture of H2S, SO2, NO2, and Cl2 at concentrations ranging from 10 ppb to 500 ppb, ensuring accurate replication of corrosive atmospheres. Mass Flow Controllers (MFCs) maintain stable flow rates between 0.5 and 2.0 mL/min per gas, enabling consistent exposure for all samples.

Multi-Factor Coupling for Environmental Reliability Testing:

Temperature (15–80°C), relative humidity (30–98% RH), and gas concentration are coupled to mimic real-world atmospheric stress. The chamber maintains these parameters dynamically over long-duration tests, allowing complex interactions between humidity, heat, and corrosive gases to accelerate material aging realistically.

LIB industry Advantage:

By combining high-precision gas metering with uniform airflow design, LIB industry ensures that every sample experiences the same corrosive conditions. The result is reproducible, high-confidence testing critical for material screening and product development.

So2 concentration | 100 ~500 ppb± 20 ppb (Adjustable) | |||||

H2S concentration | 10 ~100 ppb ± 20 ppb (Adjustable) | |||||

No2 concentration | 200 ppb ± 20 ppb (Adjustable) | |||||

Cl2 concentration | 10 ~20 ppb ±5 ppb (Adjustable) | |||||

Error in maintaining the concentration | 10% | |||||

Cooling

| Cooling system | Mechanical compression refrigeration system | ||||

Refrigerating unit | French TECUMSEH compressor | |||||

Refrigerant | Environmentally friendly refrigerant | |||||

Heating Element | Nichrome heater | |||||

Humidity

| Humidifier | External isolation, stainless steel surface evaporation humidifier | ||||

Water Supply System | Water purification system, Automatic water supply | |||||

Dehumidification | Evaporator | |||||

Controller | Programmable color LCD touch screen controller, Ethernet connection, USB port | |||||

Sensor

| Temp Sensor | PT100Ω / MV A-class | ||||

Humidity Sensor | Dry and wet bulb sensor | |||||

Gas Sensor 1 | SO2 sensor | |||||

Gas Sensor 2 | H2S sensor | |||||

Gas Sensor 3 | No2 sensor | |||||

| Gas Sensor 4 | Cl2 sensor | |||||

|

| |||||

Step 1: Sample Preparation and Arrangement for Precision Material Exposure

Samples such as PCBs, electroplated connectors, and metallic coatings are cleaned to remove oils and contaminants. Adjustable racks and trays allow uniform exposure, while airflow channels maintain 0.5–2.0 m/s gas circulation, eliminating concentration gradients. LIB industry’s flexible sample setup accommodates varied sizes and geometries without compromising uniformity.

Step 2: Environmental Parameter Setup and Precise Control for Accelerated Corrosion

Operators set target gas concentrations (e.g., H2S 100 ppb, SO2 150 ppb, NO2 200 ppb, Cl2 50 ppb), temperature (40°C), and relative humidity (85% RH). MFCs inject gases continuously at microgram-level precision, while internal fans circulate the air, achieving consistent exposure across all samples. This precision ensures accelerated corrosion progresses in a controlled, predictable manner.

Step 3: Real-Time Monitoring and Closed-Loop Adjustment for Reliable Testing

High-sensitivity sensors—electrochemical for H2S and UV-fluorescence for SO2—monitor gas concentrations, temperature, and humidity. Deviations trigger automatic MFC adjustments, maintaining ppb-level stability throughout long-term tests. LIB industry’s closed-loop system ensures reproducibility even for 14–21 day accelerated tests simulating multiple years of natural corrosion.

Step 4: Data Logging and Analysis for Material Reliability Assessment

All parameters, including gas concentrations, temperature curves, and flow rates, are digitally logged. Engineers can analyze corrosion rates, identify vulnerable areas, and refine material selections using reliable, traceable data.

Step 5: Test Completion and Sample Handling in Noxious Gas Test Chamber

After the test, residual gases are safely purged and the chamber automatically cleaned. Samples are extracted for visual inspection, weight loss analysis, or electrical testing. Reproducibility and safety are ensured, making long-term testing practical and efficient.

Standards Compatibility for Accelerated Corrosion Testing:

IEC 60068-2-60: Environmental testing for electronics – mixed flowing gas corrosion.

ASTM G85: Modified salt spray test with SO2 injection.

ISO 21207: Corrosion testing in artificial atmospheres.

Data Traceability for Material Testing Confidence:

LIB industry’s digital logging system records every parameter in real time, ensuring full traceability and enabling high-precision lifetime modeling.

Brand Advantage:

The chamber provides reproducible, standard-compliant corrosion testing, while LIB industry’s advanced control systems guarantee accurate, long-duration experiments that meet the strictest global testing requirements.

Critical Component Verification in Accelerated Corrosion Testing:

Gold, silver, and nickel electroplated layers

PCB solder mask and conductive traces

Connector contacts exposed to complex atmospheric environments

R&D Cycle Optimization through Accelerated Testing:

Tests that would take years in natural conditions can be completed in 14–21 days, providing statistically significant results.

Accelerated testing enables faster material evaluation, design validation, and product optimization.

LIB industry Advantage:

The chamber supports continuous testing under diverse conditions, allowing simultaneous evaluation of multiple samples and materials. Its high precision and reliability significantly reduce development time and improve product lifecycle performance.

The LIB industry Noxious Gas Test Chamber is a high-precision research tool that enables:

Quantitative analysis of corrosion and failure mechanisms

Optimization of materials and protective coatings

Reliable, reproducible accelerated testing aligned with international standards

With ppb-level gas control, uniform airflow, closed-loop monitoring, and full data traceability, LIB industry’s noxious gas chamber provides researchers and engineers the confidence to predict material longevity, improve product reliability, and shorten development cycles.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia