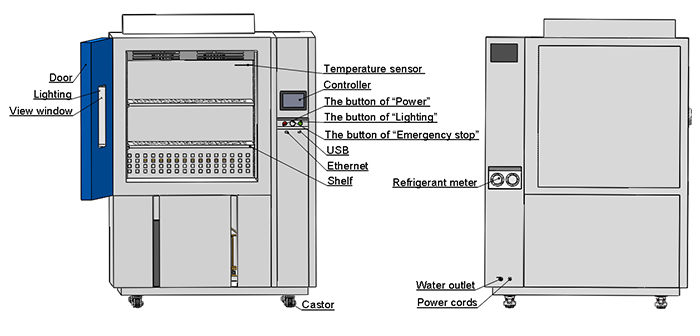

From –70°C to +150°C — Reliable Thermal Testing for Automotive, Aerospace, Electronics, and Material Applications

High-low temperature testing may seem routine, but in reality, it is one of the most failure-sensitive stages in product validation. Even minor temperature drift, uneven distribution, or instability during prolonged cycling tests can silently invalidate results—without immediate detection.

Imagine an automotive electronic module: a small fluctuation can cause intermittent failures in the field, leading to recalls and production delays. Aerospace components may fail certification if thermal conditions are uncontrolled.

The takeaway: if the testing environment itself is unreliable, all test data is meaningless—making a dependable chamber critical.

Not all chambers are created equal. True reliability goes beyond extreme temperature numbers—it is measured in accuracy, stability, and repeatability under real testing conditions.

|

|

Critical Capabilities Every Professional High-Low Temperature Test Chamber Must Have:

Temperature Accuracy & Uniformity – Every sample must experience the same thermal conditions.

Long-Duration Stability – Maintains performance during continuous 24/7 operation.

Heating & Cooling Rate Under Load – Fast transitions must remain consistent even with fully loaded chambers.

Control System Reliability – Supports complex profiles, precise PID regulation, and unattended operation.

Safety & Failure Protection – Comprehensive safeguards for samples, equipment, and personnel.

These are not optional—they are the baseline standards for a high and low temperature test chamber that produces trustworthy results every time.

LIB industry high-low temperature test chambers are engineered around real-world testing challenges, not just paper specifications. Every design decision focuses on delivering accuracy, stability, efficiency, and safety, ensuring your lab can trust every test result.

Imagine an automotive R&D lab running a 72-hour thermal cycle on a new electronic module. Outside, temperatures swing from –70°C to +150°C. Inside the LIB chamber, every component experiences exactly the conditions it should.

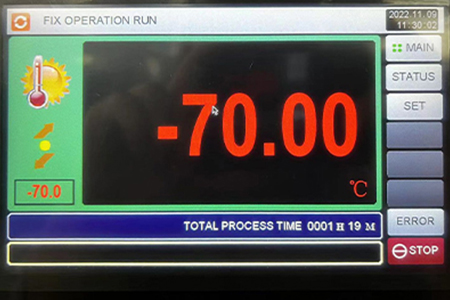

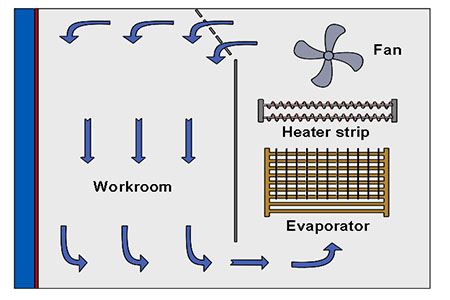

Thanks to independent PID control and optimized airflow circulation, temperature across the entire working volume remains within ±0.5°C, even during extended continuous operation. Engineers can monitor results remotely, confident that no drift or hotspot compromises the data.

|  |

| Programmable Logic Controller | Air Circulation System |

Customer Value:

Reduced retesting

Faster validation

Confidence in pass/fail decisions

Instead of listing functions, LIB capabilities can be presented as interactive card-style modules:

| Problem | LIB Industry Solution | Customer Benefit |

|---|---|---|

| Temperature drift during long cycles | Independent PID + optimized airflow | Stable ±0.5°C, reliable data |

| Uneven temperature distribution | Precision-engineered air ducts & balanced airflow | All samples receive identical thermal exposure |

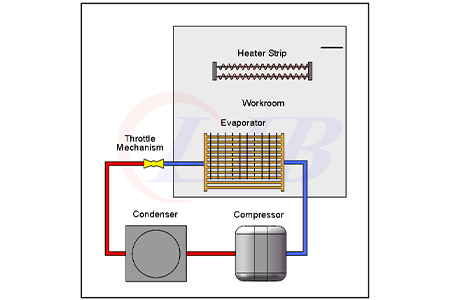

| Slow heating/cooling under load | High-capacity heating & industrial-grade refrigeration | Shorter validation cycles, higher lab throughput |

| Risk of sample/equipment damage | Multi-layer safety systems: over-temp alarms, fault detection, power failure memory | Protected samples & safe lab operation |

Presenting LIB industry temp and humidity chamber capabilities along the real testing workflow makes performance tangible:

Sample Loading – Multiple modules installed, heavy load handled without performance loss.

Rapid Heating & Cooling – Industrial-grade systems maintain target rates under full load.

Stable Thermal Cycling – Optimized airflow ensures uniform temperature across all samples.

Continuous Monitoring – Advanced controller logs data, supports unattended operation.

Safe Shutdown & Recovery – Multi-layer safety protection ensures equipment and samples are safe even during unexpected events.

Customer Value: Lab managers can visualize end-to-end reliability, increasing confidence in testing decisions.

Rather than dry specifications, LIB presents technical parameters as evidence of capability:

Temperature Range: –70°C to +150°C

Supports automotive, aerospace, electronics, and materials testing.

Temperature Accuracy: ±0.5°C

Repeatable, auditable results suitable for compliance and certification.

Temperature Uniformity: Optimized airflow ensures consistent exposure across the test volume.

Heating & Cooling Performance: Maintains efficiency under full load, shortening validation cycles.

Industrial-Grade Construction: Reliable for long-term 24/7 operation.

|  |

LIB industry high-low temperature test chambers are used in a wide range of applications:

Automotive Electronics & EV Components – Validate reliability under extreme thermal conditions.

Aerospace Materials & Assemblies – Ensure certification standards are met.

Industrial Electronics & Power Modules – Test performance under stress cycles.

Pharmaceutical & Packaging Validation – Guarantee product stability and safety.

High-low temperature testing is a long-term capability, not a one-time purchase. LIB industry ensures:

Customized Configurations: Tailored chamber sizes and performance parameters for your lab.

Engineering & Manufacturing Control: Full oversight ensures consistent quality.

Technical Support: Experienced engineers respond in 1–3 hours to minimize downtime.

Global Spare Parts: Standardized components delivered worldwide.

Lifecycle Reliability: Chambers designed for years of continuous operation.

Customer Value: Confidence that your testing capability remains stable, scalable, and dependable for years.

Contact LIB industry today to:

Discuss your testing requirements

Receive a tailored configuration

Ensure your high-low temperature testing delivers results you can trust

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia