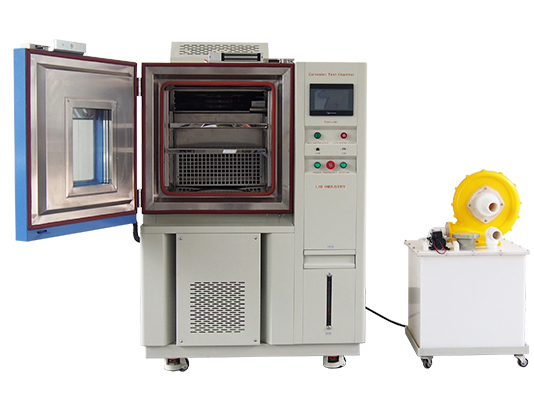

A corrosive gas test chamber is a specialized environmental testing device designed to expose products, components, and materials to controlled concentrations of corrosive gases such as sulfur dioxide, hydrogen sulfide, or chlorine. The equipment allows engineers and researchers to evaluate how materials react to chemical exposure over time, providing critical insights into corrosion resistance, coating durability, and product longevity.

Inside LIB Industry's corrosive gas test system, environmental parameters such as temperature, humidity, and gas concentration are precisely controlled to simulate real-world conditions. The integration of advanced sensors and automated control systems ensures uniform exposure and reliable, repeatable results. This precision enables accelerated aging tests and performance analysis, helping manufacturers identify potential weaknesses and improve material selection and design before mass production.

The noxious gas test chamber plays a vital role in product development and quality assurance by simulating harsh chemical environments that products might encounter during use. Corrosion can lead to material degradation, loss of functionality, and premature failure, particularly in industries such as automotive, electronics, aerospace, and infrastructure.

Using LIB Industry's noxious gas test chamber, engineers can observe how different coatings, alloys, or protective treatments withstand chemical attack. Precise control of gas composition, temperature, and humidity ensures consistent and scientifically valid testing conditions. By exposing products to controlled corrosive environments, manufacturers can identify vulnerabilities in materials or design, optimize protective coatings, and ensure that end products maintain their functionality and safety under challenging conditions.

A mixed gas test chamber is capable of replicating complex chemical exposure scenarios to evaluate material resilience. LIB Industry's system allows for the regulation of gas concentration, temperature, and humidity, enabling simulation of both short-term and long-term exposure conditions.

The design ensures uniform gas distribution so that all test specimens experience consistent chemical attack. Programmable cycles allow testing under varying levels of stress, mimicking real-world fluctuations in environmental conditions. This ability to simulate precise corrosive conditions helps engineers assess product performance across multiple scenarios, providing valuable data for improving corrosion resistance and extending operational life. Continuous monitoring systems track gas levels and environmental conditions, ensuring accurate data collection and repeatability for research or quality control.

| Model | GCM-100 | GCM-225 | GCM-500 |

| Internal Dimensions (mm) | 400*500*500 | 500*600*750 | 700*800*900 |

| Overall Dimensions (mm) | 1010*1050*1620 | 1110*1150*1860 | 1330*1350*2010 |

| Interior Volume (L) | 100 | 225 | 500 |

| Temperature Range | 15 ℃ ~ 80 ℃ | ||

| Humidity Range | 30% ~ 98% RH | ||

| SO2 Concentration | 100 ~500 ppb± 20 ppb (Adjustable) | ||

| H2SConcentration | 10 ~100 ppb ± 20 ppb (Adjustable) | ||

| NO2Concentration | 200 ppb ± 20 ppb (Adjustable) | ||

| Cl2concentration | 10 ~20 ppb ±5 ppb (Adjustable) | ||

| Air Change Rate | 3~10times /h | ||

| Cooling system | Mechanical compression refrigeration system | ||

| Controller | Programmable color LCD touch screen controllerEthernet connection, PC Link | ||

| Gas Sensor | H2S/NO2/CL2/SO² gas sensor | ||

| Air Circulation | Centrifugal wind fan | ||

| Door Lock | Electromagnetic lock | ||

| Gas Exhaust Device | Exhaust Unit | ||

| Interior material | SUS316 stainless steel +Glass fiber reinforced plastics | ||

The corrosive gas test system has wide applications across industries requiring robust corrosion testing:

Automotive – Durability tests for metal parts, fasteners, and coatings exposed to exhaust gases or pollutants.

Electronics – Chemical resistance testing for connectors, PCBs, and enclosures.

Aerospace & Defense – Reliability testing of structural materials and instruments under severe environments.

Construction & Infrastructure – Corrosion resistance assessment for metals, paints, and protective coatings.

LIB Industry's advanced control ensures accurate, repeatable conditions, helping engineers understand material behavior under chemical stress and develop durable, high-performance designs.

LIB Industry's mixed gas test chamber combines advanced design, precision control, and reliability to support comprehensive corrosion testing. Each model meets ISO 6988, ISO 3231, DIN 50018, ASTM G87-02, IEC 60950:22, and IEC 60068-2-60 standards. The intelligent control system enables accurate adjustment of gas concentration, temperature, and humidity for consistent, repeatable results.

LIB Industry provides full lifecycle support — including installation, training, and calibration — ensuring smooth operation and dependable testing. By using LIB Industry's noxious gas test chamber, manufacturers can validate corrosion resistance, enhance product design, and ensure long-term performance in chemically aggressive environments.

Ready to evaluate your materials against harsh noxious gases? Contact LIB Industry at inquiry@libtestchamber.com and receive your custom testing solution within 1–3 hours.

✔ 16+ years of manufacturing experience

✔ 3-year warranty and lifetime service support

✔ Global technical service network for fast response

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia