A Practical Buyer’s Guide to Reliable Rubber Ozone Aging Testing

When customers specify “ozone resistance”, many laboratories still rely on a simplified routine:

set the ozone concentration to 50 pphm, stretch the specimen, start the test, and wait for cracks.

On paper, the test looks compliant.

In practice, it may be technically meaningless.

Ozone resistance is not defined by a single parameter. It is a system, governed by test standards, strain behavior, conditioning rules, and—most critically—the capability of the ozone test chamber itself. ASTM D1149 and ISO 1431 are not interchangeable checkboxes; they are based on fundamentally different assumptions about how rubber degrades in real environments.

Choose the wrong standard—or use an ozone test chamber that cannot truly execute it—and your product may pass laboratory testing flawlessly, only to fail prematurely in service. In other cases, excessive safety margins lead to over-designed compounds and unnecessary production costs.

This article explains the real differences between ASTM D1149 and ISO 1431, and why the ozone test chamber is often the deciding factor between nominal compliance and meaningful results.

Below is not just a standards comparison, but a practical selection guide for ozone test chamber capability.

| Feature | ASTM D1149 | ISO 1431-1 | Ozone Test Chamber Requirement |

|---|---|---|---|

| Test Focus | Surface crack evaluation under controlled ozone | Static & dynamic strain ozone aging | High ozone stability & uniform exposure |

| Strain Mode | Static strain | Static (Part 1) / Dynamic (Part 2) | Servo-controlled stretching system |

| Evaluation Criteria | Crack appearance time & grading | Critical strain & crack growth rate | Long-term concentration consistency |

| Conditioning Requirement | Mandatory rest after stretching | Strict pre-conditioning timing | Programmable conditioning control |

| Typical Applications | General rubber screening | Automotive & dynamic components | High-load, continuous operation design |

| Market Preference | North America | Global / Automotive industry | Multi-standard preset programs |

Key takeaway:

A chamber that merely “supports ozone testing” does not automatically support ASTM D1149 or ISO 1431 compliance in real testing environments.

One of the most overlooked variables in ozone aging tests is conditioning time.

After stretching, rubber undergoes molecular stress relaxation and chain rearrangement. Both ASTM D1149 and ISO 1431 explicitly require specimens to rest in an ozone-free environment—often 24 or 48 hours—before ozone exposure begins.

In real laboratories, this step is frequently:

Manually timed

Poorly documented

Or skipped entirely under schedule pressure

The result is predictable: poor repeatability, conflicting test data, and failed audits.

Conditioning should not be treated as a “human task.”

It must be built into the chamber’s control logic.

LIB industry ozone test chambers integrate conditioning countdown control directly into the system, enabling:

Automated transition from conditioning to ozone exposure

Elimination of manual timing errors

Full traceability for audits and certification reviews

This capability alone often explains why the same rubber compound passes in one laboratory and fails in another.

Static ozone testing is suitable for fixed seals and gaskets.

However, most rubber components fail under motion, not at rest.

ISO 1431 introduces dynamic strain testing, which is essential for:

Tires

Wiper blades

Conveyor belts

Flexible automotive seals

Dynamic ozone exposure introduces challenges that many chambers cannot handle:

Localized heat generation

Ozone concentration drift during cyclic motion

Mechanical fatigue under long-duration testing

Many ozone test chambers claim ISO 1431 compliance, yet quietly:

Exclude dynamic strain testing

Or limit testing duration to short cycles

LIB industry ozone test chambers are engineered specifically for dynamic ISO 1431 testing, featuring:

Servo-motor-driven strain systems

Programmable strain frequency and amplitude

Optimized airflow design for rapid ozone concentration recovery

This ensures that dynamic ozone testing reflects real service conditions, not laboratory compromises.

Understanding ASTM D1149 or ISO 1431 defines what to test.

Executing those standards correctly determines whether the result is credible.

LIB industry ozone test chambers are designed around standard execution, not approximation.

Pre-installed ASTM D1149, ISO 1431-1, ISO 1431-2, and JIS K6259 programs

One-click standard selection

Parameter locking to prevent manual misconfiguration

UV absorption ozone concentration sensors

Closed-loop feedback control

Stability within ±10%, with optional ±5% for critical testing

Servo-driven stretching mechanism

Continuous, fatigue-resistant operation

Fully aligned with ISO 1431 dynamic strain requirements

|  |

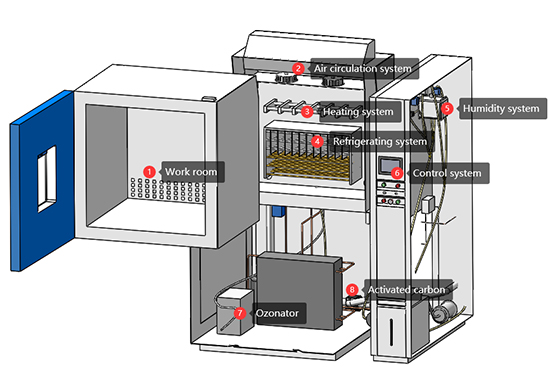

| Workroom | |

Conditioning time records

Ozone concentration curves

Test duration and strain logs

Model | OC-250 | OC-500 | OC-800 | OC-010 |

Interior Volume (L) | 250 | 500 | 800 | 1000 |

Temperature Range | 0℃ ~ +100 ℃ | |||

Temperature Fluctuation | ± 0.5 ℃ | |||

Temperature Deviation | ± 2.0 ℃ | |||

Humidity Range | 30% ~ 98% RH | |||

Humidity Deviation | ± 2.5% RH | |||

Cooling Rate | Ambient ~ 0℃ within 20 min | |||

Ozone Concentration | 1~1000PPHM | |||

Sample Holder Rotate Speed | 0~10 r/min | |||

Airflow Rate | 0 ~ 60L/min | |||

Clamps Tensile Stretch | 5%~35% | |||

Controller | Programmable color LCD touch screen controller Ethernet connection, PC Link | |||

Gas Sensor | Ozone gas sensor | |||

Ozone Generator | Silent discharge type ozone generator | |||

Air Circulation | Centrifugal wind fan | |||

Sample Holder | Static + dynamic combined sample holder | |||

Interior Material | SUS304 stainless steel | |||

|  | |||

Designed for automotive qualification, third-party audits, and global certification requirements.

A:The ozone sample rack can stretch rubber and elastomer specimens within a 5% to 50% strain range, adjustable according to test requirements.

Two configurations are typically available:

Static stretching racks, designed for fixed-strain ozone aging tests

Dynamic stretching systems, which support cyclic strain for ISO 1431 dynamic ozone testing

This flexibility allows the chamber to meet different aging evaluation objectives, from basic material screening to dynamic service simulation.

A:Ozone is a strong oxidizing gas and must be safely neutralized before discharge. The ozone test chamber uses an activated carbon adsorption system to decompose and absorb residual ozone.

Based on engineering experience, an appropriate amount of activated carbon is preconfigured. For example:

Approximately 2.5 kg of activated carbon is used for every 1000 L of exhaust gas

To ensure long-term purification efficiency, it is recommended to replace the activated carbon annually. When properly sized and maintained, this system effectively reduces ozone concentration to safe levels before air discharge.

A:Yes. According to ISO 1431-1, the dynamic stretching frequency of a combined static-dynamic ozone test chamber can be set to 0.5 Hz.

This frequency is a standard configuration and can be:

Accurately set

Clearly displayed

Adjusted directly on the controller interface

This ensures full compliance with ISO 1431 dynamic ozone aging requirements.

A:Yes. The dynamic stretching speed can be displayed in mm/s on the controller, allowing operators to intuitively monitor and adjust test parameters.

According to ISO 1431-1 requirements, the system can achieve a dynamic speed range of 20–25 mm/s, which is supported as a standard feature.

A:Yes. Ozone does not corrode 304 stainless steel, making it highly suitable for long-term ozone aging applications. The workroom maintains excellent corrosion resistance and structural stability over extended use.

Compared with fiberglass, stainless steel offers several advantages:

Superior durability and long service life

Smooth surface for easy cleaning and maintenance

Resistance to aging, deformation, and surface degradation

For these reasons, stainless steel is the preferred material for ozone test chamber workrooms.

Talk to LIB industry engineers to configure an ozone test chamber tailored to:

Your selected standard

Your application type

Your compliance and durability targets

You will enjoy

Efficient project execution

Fast manufacturing and delivery schedules

1~3 hours Responsive technical communication

Global service experience

3-year Long-term technical support

Stable operation throughout the chamber lifecycle

Contact us today at inquiry@libtestchamber.com to get your tailor made solution and to obtain specs.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia