How LIB industry walk in climatic chambers deliver accuracy, uniformity, and reliability at scale

From electronics and automotive systems to energy infrastructure and medical equipment, modern product development relies heavily on environmental reliability testing. Temperature, humidity, and cyclic stress simulations are no longer optional—they are decisive factors in whether a product survives the market.

However, many laboratories face a growing trust gap when running long-duration tests in large walk-in environmental chambers. During extended cyclic testing—especially at critical conditions such as 0°C with high humidity—older or low-end systems often lose control. Temperature overshoot, humidity drift, or unstable airflow can invalidate weeks of accumulated data in a matter of hours.

This issue is not limited to a specific test item or industry. It affects any organization relying on walk in environmental chambers for long-term, high-load environmental simulation. At LIB industry, we design walk-in environmental chambers specifically to eliminate these failures—delivering precision that lasts not just for hours, but for weeks.

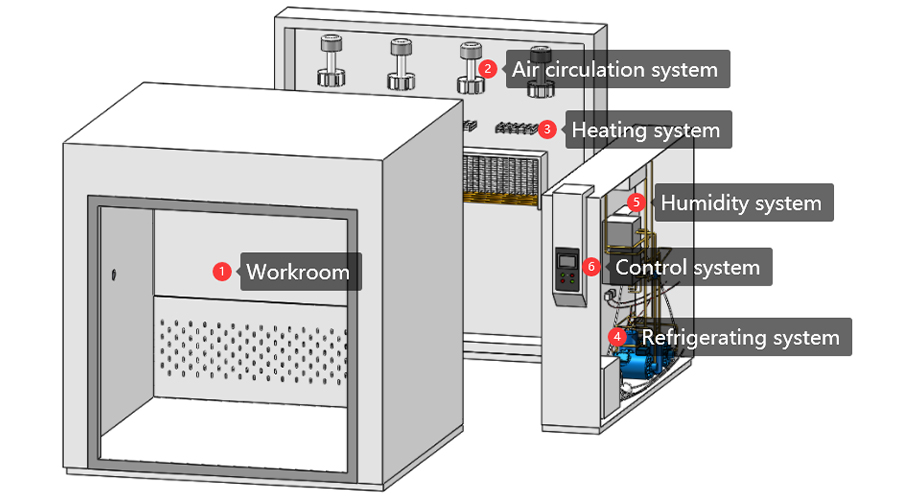

A truly reliable walk in environmental chamber must do more than reach a setpoint. It must maintain accuracy, uniformity, and stability across a large volume under continuous operation. LIB industry walk in climatic chambers are built around four essential technical pillars.

In large walk-in climatic chambers, precision is not achieved by brute force cooling or heating. The real challenge lies in maintaining thermal balance while temperature and humidity change simultaneously.

LIB industry integrates PID control, PWM regulation, and electronic expansion valves (EEV) into a coordinated control architecture. This system actively compensates for one of the industry’s most persistent problems: temperature disturbance caused by humidification heat input.

As a result, the walk in environmental chamber operates within extremely tight tolerances—typically ±2.5°C temperature deviation and ±5% RH humidity control, even during aggressive cyclic transitions. This level of control ensures data integrity in critical test windows where instability most commonly occurs.

A walk-in environmental chamber is defined not only by its volume, but by what it can carry.

LIB industry walk in climatic chambers feature reinforced floor structures designed for heavy test loads, such as battery racks, automotive assemblies, power cabinets, or industrial fixtures. The internal structure is engineered to withstand repeated thermal expansion and contraction without deformation.

The inner chamber is constructed from high-grade stainless steel, providing excellent resistance to corrosion under long-term high-humidity conditions or combined environmental stresses. This durability makes the chamber suitable not only for laboratory testing, but also for pre-production and production-line validation.

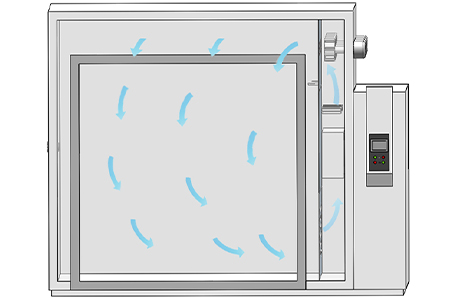

Achieving uniform temperature and humidity in a large chamber is fundamentally different from controlling a benchtop or reach-in unit.

LIB industry walk in environmental chambers employ engineered airflow channels and optimized circulation paths, ensuring consistent environmental distribution throughout the entire working space. Even when the chamber is fully loaded with bulky test items—such as vehicle front-end modules or server racks—the temperature and humidity fields remain stable and uniform.

This intelligent airflow design is essential for eliminating hot spots, condensation zones, and local deviations that can compromise test repeatability.

Many walk-in climatic chambers perform well during short tests. The real test of quality begins during multi-week cyclic operation.

LIB industry designs its systems for continuous testing cycles of six weeks or longer, incorporating automatic defrost strategies, high-efficiency heat exchange, and industrial-grade refrigeration systems. Core components, including compressors from globally recognized brands such as Bitzer, ensure consistent performance under sustained load.

| |

|

|

|

|

In addition, remote monitoring and alarm systems allow engineers to supervise test status in real time, enabling safe unattended operation and minimizing downtime risk.

Thanks to their scale, stability, and flexibility, LIB industry walk in environmental chambers are widely applied across multiple sectors:

Automotive & Transportation

Environmental testing of pedal assemblies, dashboards, battery packs, charging stations, and complete subsystems.

Electronics & Telecommunications

Thermal and humidity stress testing for 5G base stations, large server clusters, and communication cabinets.

New Energy & Power Systems

Long-term damp heat aging simulations for photovoltaic inverters, energy storage cabinets, and power electronics.

Medical & Life Sciences

Operating environment simulation for large imaging equipment, as well as pharmaceutical stability testing under controlled climatic conditions.

These applications all share a common requirement: large-scale, long-duration, and high-reliability environmental control—the core strength of a professional walk in climatic chamber.

LIB industry provides a complete portfolio of walk-in environmental chambers, including walk-in temperature and humidity chambers, salt spray corrosion chambers, dust and sand test chambers, and rain test chambers. In addition, customized walk-in climatic chambers can be engineered to meet specific test standards, sample dimensions, and installation conditions.

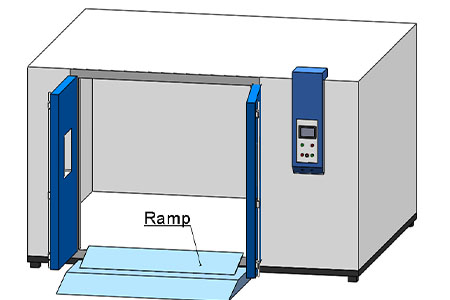

For the TH series, a walk-in environmental chamber is recommended when test specimens exceed approximately 1.8 meters in height or involve heavy or bulky samples. A walk-in design improves loading efficiency and operational safety. Considerations typically include ventilation, personnel access, and safe operation during testing and maintenance. LIB industry supports full non-standard customization based on actual application needs.

In modular walk-in climatic chambers, minor gaps between panels may occur during on-site assembly. LIB industry addresses this using mechanical locking systems combined with sealing materials and professional joint treatment, ensuring reliable airtightness and liquid tightness while maintaining ease of maintenance.

Delivery time depends on the chamber size, configuration, and level of customization. Standard walk-in environmental chambers usually require several weeks for production, while fully customized walk-in climatic chambers may take longer. LIB industry confirms the delivery schedule during technical clarification to ensure it aligns with your project timeline.

For projects with tight schedules or special site conditions, LIB industry can provide tailored delivery and service plans for walk-in environmental chamber solutions.

Many customers approach LIB industry after experiencing repeated failures with refurbished or pieced-together systems. In most cases, the issue is not a single component—it is system incompatibility caused by fragmented design responsibility.

LIB industry provides fully integrated walk in climatic chamber solutions, covering system design, manufacturing, installation, commissioning, and after-sales support. By delivering the entire system as a unified solution, we eliminate interface risks, ensure long-term compatibility, and significantly reduce lifecycle costs.

For complex cyclic testing and large-scale environmental simulation, integration is not a luxury—it is a necessity.

If your walk in environmental chamber struggles with stability during complex cyclic testing, or if you require a customized walk in climatic chamber for large components and long-term operation, LIB industry’s application engineers are ready to support your project.

Efficient project execution

Fast manufacturing and delivery schedules

1~3 hours Responsive technical communication

Global service experience

3-year Long-term technical support

Stable operation throughout the chamber lifecycle

Contact us inquiry@libtestchamber.com to discuss your testing requirements and discover how precision can be maintained—even under pressure.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia