In today’s industrial environment, traditional Neutral Salt Spray (NSS) testing is no longer sufficient.

Industries such as automotive manufacturing, photovoltaic systems, marine engineering, and outdoor electronics are facing increasingly aggressive service conditions. Real-world corrosion is no longer driven by salt alone — it is the result of industrial pollutants, acidic gases, humidity condensation, and cyclic stress acting together.

Among these pollutants, sulfur dioxide (SO₂) plays a decisive role. Combined with moisture, it forms acidic condensates that rapidly attack metal coatings, fasteners, connectors, and polymer materials.

This is why ISO 6988 and ASTM G85 (especially Annex A4) are now regarded as the gold standards for evaluating high-end corrosion resistance. Passing these tests is no longer optional — it is a prerequisite for market access and long-term reliability.

ISO 6988 focuses on corrosion testing in a humid sulfur dioxide atmosphere.

Unlike standard salt spray tests, this method emphasizes:

High relative humidity

Controlled SO₂ gas concentration

Acidic condensation on material surfaces

The real challenge lies in the synergistic effect: moisture accelerates SO₂ absorption, forming corrosive acids that penetrate coatings, seams, and microcracks.

Many materials that perform well under NSS conditions fail rapidly under ISO 6988, not due to poor material quality, but because the corrosion mechanism is fundamentally different.

ASTM G85 Annex A4 introduces a more realistic and aggressive corrosion model, including:

Acidified salt spray

Alternating wet, dry, and humidity cycles

Repeated environmental stress rather than continuous exposure

This cyclic approach simulates real outdoor and industrial conditions, where materials experience temperature changes, drying periods, and acidic reactivation.

The complexity of Annex A4 means that parameter drift, unstable spray deposition, or poor cycle control can invalidate test results entirely.

| Dimension | NSS Salt Spray | ISO 6988 / ASTM G85 |

|---|---|---|

| Corrosion Mechanism | Chloride attack | Acidic gas corrosion + salt synergy |

| Exposure Pattern | Static, continuous | Cyclic, reactivated corrosion |

| Result Stability | Easy to repeat | Highly sensitive to control accuracy |

| Typical Failure Risk | Low | High if equipment is not purpose-built |

This is exactly where conventional salt spray chambers reach their limits — and where advanced systems designed specifically for ISO 6988 and ASTM G85 become essential.

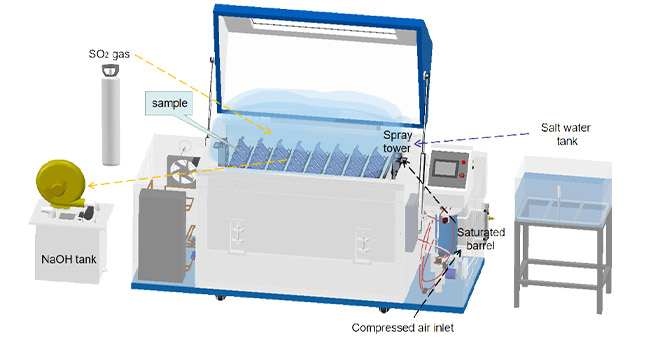

The LIB industry salt fog and SO2 corrosion chamber SSC Series is engineered specifically for advanced corrosion standards.

It integrates:

Salt spray exposure

SO₂ gas corrosion

High-humidity condensation

Drying and heating phases

Model | SSC-010 | SSC-016 | SSC-020 |

Interior Volume (L) | 780 | 1280 | 1800 |

Temperature Range | +10 ℃ ~ +90 ℃ | ||

Temperature Fluctuation/Deviation | ± 0.5 ℃/± 2.0 ℃ | ||

Humidity Range | 30% ~ 98% RH | ||

Humidity Deviation | + 2%, - 3% | ||

Salt Fog Deposition | 1~2ml / 80cm2 · h | ||

SO2 Gas Control | Control and display volume of SO2 gas | ||

Controller | Programmable color LCD touch screen controller, Ethernet connection | ||

| SO2 Exhaust Device | NAOH tank | ||

| |||

One system functions as a complete environmental simulation laboratory, fully aligned with the cyclic requirements of ASTM G85 Annex A4 and the condensation demands of ISO 6988.

This eliminates the need for multiple chambers, manual transfers, and inconsistent results.

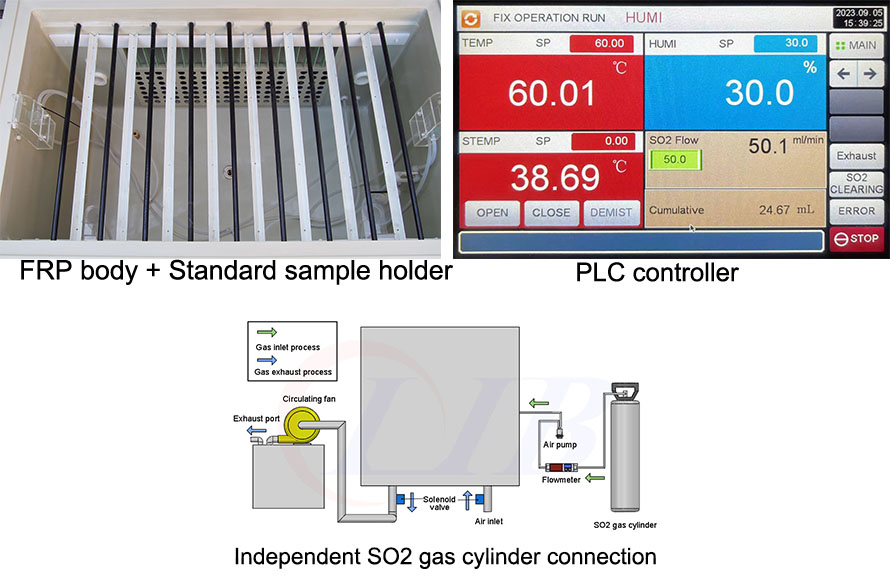

In SO₂ corrosion testing, gas concentration stability is critical.

Even slight deviations can lead to:

Abnormal corrosion rates

Poor batch-to-batch repeatability

Failure during third-party audits

LIB industry addresses this with:

Dedicated SO₂ gas cylinder interfaces

High-precision flow meters

Independent gas control loops

Every test cycle maintains SO₂ concentration strictly within standard-defined tolerances, ensuring repeatable, auditable, and defensible test results.

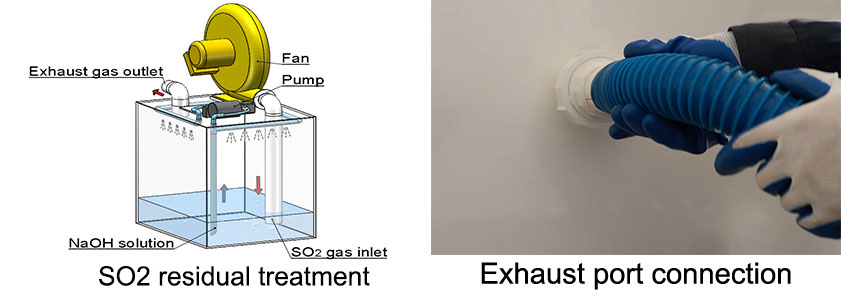

SO₂ is toxic and requires responsible handling.

The SSC Series incorporates a NaOH neutralization tank and closed-loop exhaust treatment system, which:

Neutralizes acidic gases before discharge

Meets laboratory safety and environmental compliance requirements

Protects operators and surrounding facilities

This safety architecture is not optional — it is essential for long-term SO₂ testing operations.

The Salt Fog Spray and SO2 Gas Corrosion Test Chamber

chamber interior is constructed from fiber-reinforced plastic (FRP), specifically selected for acidic corrosion environments.

Compared to conventional materials, FRP offers:

Superior resistance to SO₂ and acidic condensates

Up to 50% longer service life

Stable performance under long-term cyclic exposure

A full-color programmable touchscreen with Ethernet connectivity allows:

One-click setup of complex corrosion cycles

Remote monitoring and diagnostics

Reduced operator dependency and human error

Engineers no longer need to manually intervene during long or multi-phase tests.

Glass spray nozzles ensure:

No salt crystallization

Stable spray characteristics

Consistent deposition rates of 1–2 ml / 80 cm² · h

This guarantees compliance with ISO and ASTM requirements throughout extended test durations.

Q1: How should the liquid from a sulfur dioxide salt spray test be disposed of?

The weakly acidic liquid is safely collected through the chamber’s drainage system. It can then be neutralized and disposed of in compliance with regulations, ensuring safe, eco-friendly operation. This is part of LIB’s integrated approach to corrosion testing.

Q2: How is sealing achieved in a sulfur dioxide salt spray test?

LIB SSC chambers use pressurized doors with silicone gaskets, creating a reliable airtight seal. This ensures stable temperature, humidity, and gas concentration, delivering repeatable results while protecting operators from toxic exposure.

Q3: What type of water is required during SSC operation? Can tap water be used?

Deionized water with conductivity ≤ 5.0 µS/cm is required. Tap water may introduce impurities, affecting corrosion results and chamber longevity. Using proper water ensures consistent performance and test reliability.

Q4: How is air circulation handled in CCT and SSC chambers?

An internal air circulation system maintains uniform temperature (±2 °C) and humidity (+2%/−3% RH). This ensures all samples are evenly exposed to corrosive conditions, providing stable, repeatable results under complex cycles.

LIB industry provides more than corrosion test equipment.

The SSC-010 / SSC-016 / SSC-020 series is supported by a complete one-stop solution, including:

Laboratory planning

International standard consultation

Installation, commissioning, and training

Long-term technical support

If you are currently:

Struggling to pass ASTM G85 Annex A4 consistently

Concerned about SO₂ test safety and compliance

Required to meet multiple international corrosion standards

Then you don’t just need a salt spray chamber —

you need a partner who understands the standards behind the test.

Contact LIB industry today inquiry@libtestchamber.com to receive a customized composite corrosion solution and detailed technical specifications.

3-Year Warranty | Lifetime Technical Support | 1~3 Hours Rapid Engineering Response

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia