Core Features and Advantages of the IP66 Tightness Test Equipment

1.Guaranteed IP66 Protection – Comprehensive Water/Dust Ingress Solution

Achieve full IEC 60529 IP66 compliance with precision. Simulate real-world conditions with high-pressure water jets at 100 kPa and 100 liters/min flow through a 12.5 mm nozzle.

2. Flexible Modes for Any Product

Test everything from small electronics to large industrial devices with diverse standard and customized models . Adjustable workroom capacity and custom fixtures make it perfect for automotive, outdoor, and industrial applications.

3. Smart, Intuitive Controls

The touchscreen interface allows programmable cycles, pressure settings, and timing. Monitor dust blowing time,water pressure, flow rate, and test duration in real-time.

4. Built to Last – Safe and Efficient

Premium stainless steel SUS 304 construction resists dust and corrosion and ensures long service life. Safety interlocks prevent accidents, and fast drainage systems speed up post-test cleanup.

Technical Parameters of IP66 Tightness Test Equipment

IP6X Dust Tightness Test Equipment |

Standard Models | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight and Blowing Time | 0 ~ 99H59M |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Interior Material | SUS304 stainless steel |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

IPX6 Water Tightness Test Equipment |

Standard Model | R56-800 |

Interior Volume (L) | 800L,more workroom capacities can be customized. |

Diameter of Turntable (mm) | 600 |

Turntable Rotation Speed | 0~7r/min (Adjustable) |

Internal Diameter of IPX5 Nozzle | 6.3mm |

Internal Diameter of IPX6 Nozzle | 12.5mm |

Water Flow Rate IPX5/ IPX6 | 12.5L/min ±5% / 100L/min ±5% |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Interior Material | SUS304 stainless steel |

Observation Window | Double layer insulating glass with wiper |

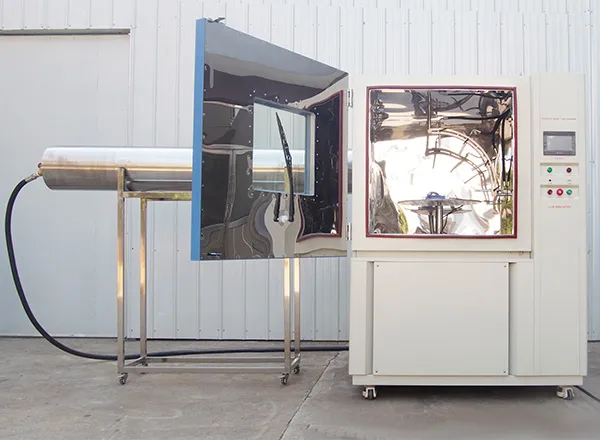

Details of IP66 Tightness Test Equipment

IP6X Dust Tightness Test Equipment |

|

|

Mirror Stainless Steel SUS304 Workroom | IP6X Vacuum |

Chamber volume options: 500 L, 800L,1000 L, 1500 L, 2000 L (customizable). Large tempered glass observation window with LED illumination. Dust circulation system ensures even particle distribution.

| Precise vacuum ports for sample pressure simulation,including pressure gauge. Fully compliant with IEC 60529 and ISO 20653 IP6X requirements.

|

|

|

Sample Holders | Intelligent Control System |

| 7-inch color touchscreen with intuitive menu interface, automatic test program. Parameters adjustable,data logging with USB export and optional Ethernet connection.

|

The LIB industry IP6X Dust Tightness Test Equipment features a sealed chamber with efficient dust circulation and comes with free talcum powder. It meets IEC 60529 IP6X standards with precise vacuum control and uniform dust exposure.

IPX6 Water Tightness Test Equipment |

|

|

SUS 304 Anti-corrosion Workroom | High-Pressure Water Spray System |

Inner material: SUS#304 stainless steel with coating. Large observation window with LED lighting for monitoring spray tests. | Nozzles deliver 100 kPa pressure water jets at a 12.5 mm diameter. Flow rate programmable to meet IPX6 test duration of 3 minutes. Compliant with IEC 60529 IPX6 and ISO 20653 standards. |

|

|

Turntable | Remote Control System |

The turntable height is adjustable, equipped with a waterproof power supply and a sample fixing device. Load capacity up to 50 kg for industrial components.

| 7-inch color touchscreen with intuitive operation. Data logging with USB export and optional remote monitoring. Automatic test programs for repeatable and consistent testing.

|

The LIB industry IPX6 tester provides precise high-pressure water spray meeting IEC 60529 IPX6 standards, features uniform water circulation.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia