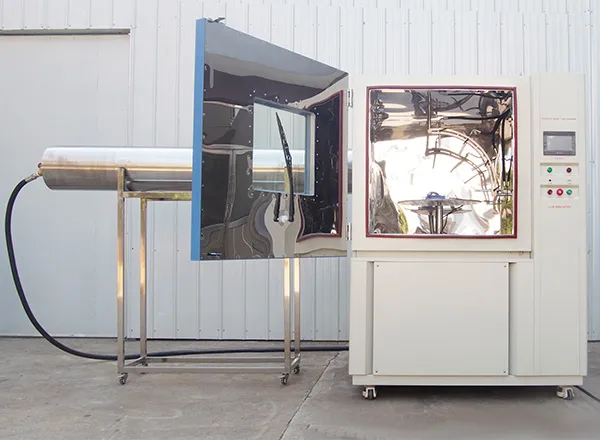

Features and Benefits of PV Climate Chamber

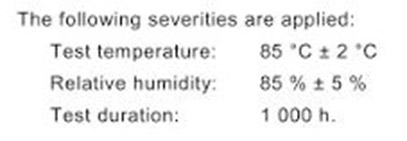

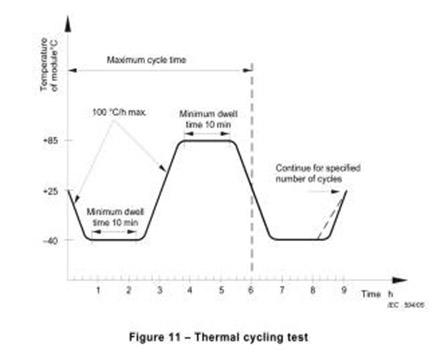

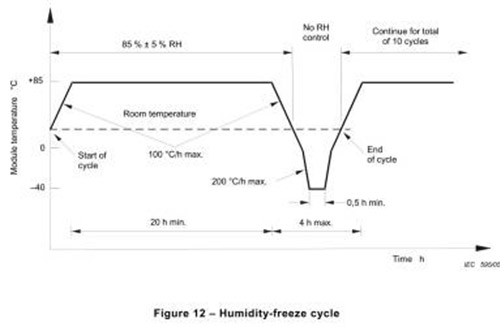

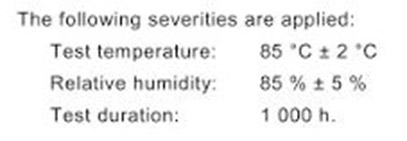

1. As a professional environmental chamber manufacturer, our pv module test chamber highly simulates the various temperature and humidity environments that photovoltaic products may encounter in the actual use process, such as climate conditions in different regions, temperature and humidity changes in different seasons, etc. Can be tested according to the standard for special points such as 85 temperature and 85 humidity.

2. The test efficiency is high, and multiple PV products can be tested at the same time, or the same product can be tested under a variety of different temperature and humidity conditions. And the rising and cooling speed of the pv climate chamber is faster.

3. Adjustable sample holder, the height of the sample holder can be adjusted to improve the applicability of different sizes of photovoltaic modules. The photovoltaic module placement Angle can also be adjusted.

4. Customized environment factors. In addition to temperature and humidity, you can also customize other environmental factors such as light, rain, wind speed, salt spray, etc., these environmental factors can be controlled individually or in combination.

Specifications of PV Climate Chamber

Model | PV-04 |

Internal Dimension (mm) | 1300*700*1350 |

Overall Dimension (mm) | 1900*1100*1750 |

Interior Volume | 1220L |

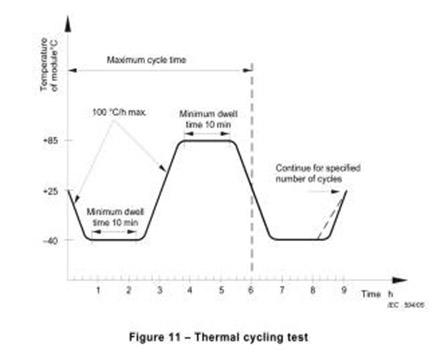

Parameter | Temperature Range | -60℃ ~ +100 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

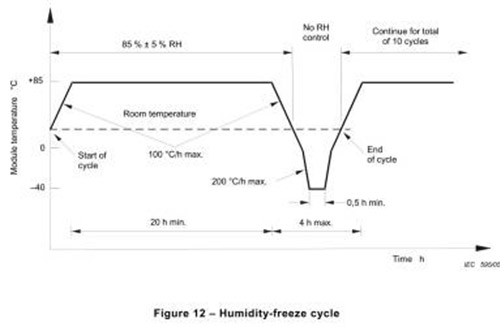

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Temperature Change Rate | 1 ~ 3.4℃ / Min |

Panel Size | 1M*2M |

Panel Capacity | 4 / 6 / 8 / 10 / 12 Pieces |

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB |

Humidity | Water supply system | Automatic water supply |

Water supply system | Water purification system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Dehumidification | Evaporator |

Sensor | Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class, accuracy 0.001℃ |

Humidity Sensor | Dry and wet bulb sensor |

Build-in Water Tank(mm) | 270*300*450 |

View Window Size(mm) | 330*370 |

Air Circulation | Centrifugal wind fan |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Refrigerant High-pressure Protection; Water Shortage Protection; Earth leakage Protection |

Configuration of PV Climate Chamber

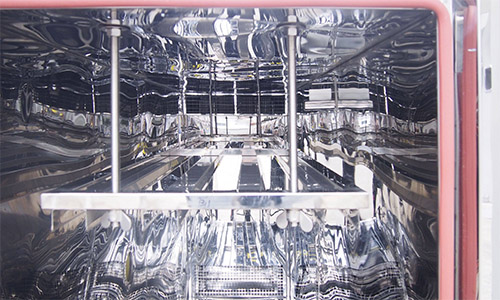

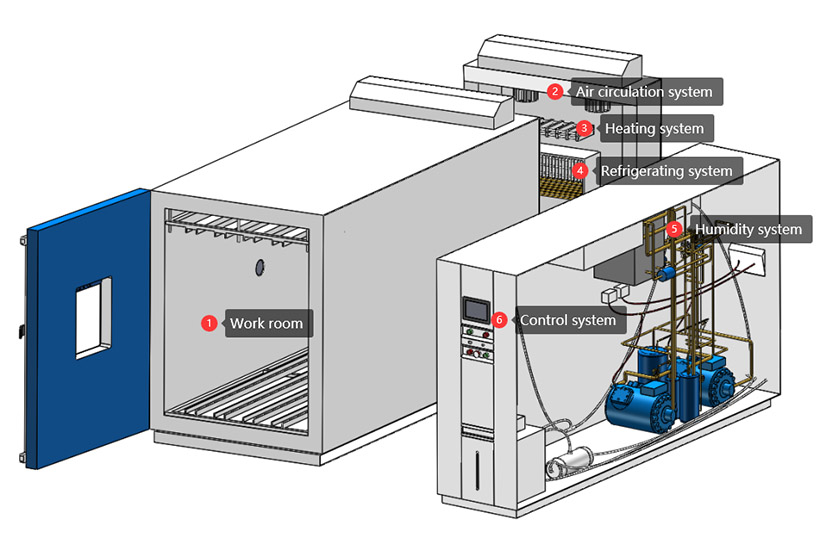

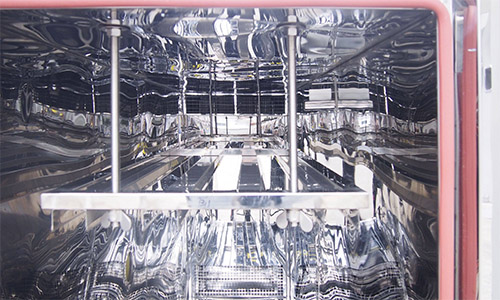

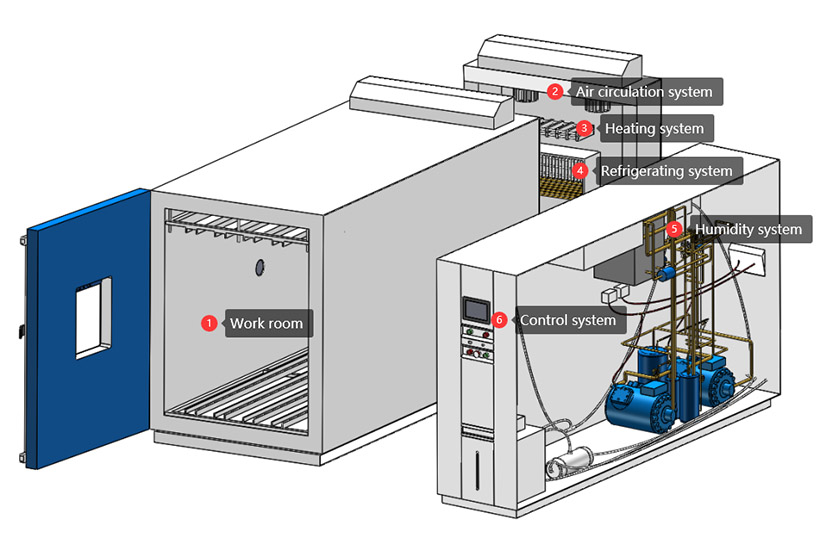

①Workroom

The workroom is generally designed as a cuboid to facilitate the placement of photovoltaic panels. The PV panel is placed upright, and the angle can be adjusted vertically,There are sample shelves at the top of the workroom to hold the PV panels in place.

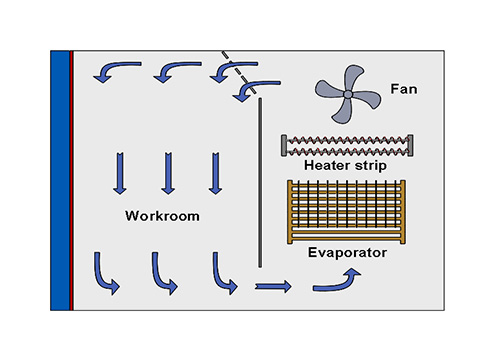

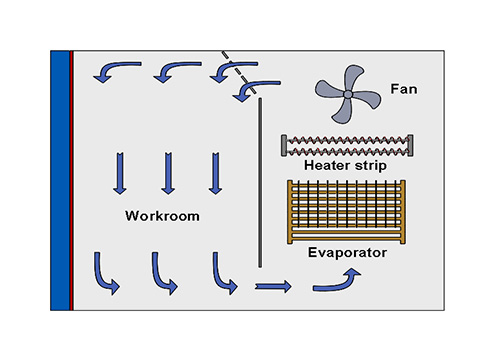

②Air circulation system

Air circulation system is composed of centrifugal fans and is the core component of the air circulation system. Since the workroom of the PV test chamber is larger, air circulation is required to ensure uniform temperature distribution.

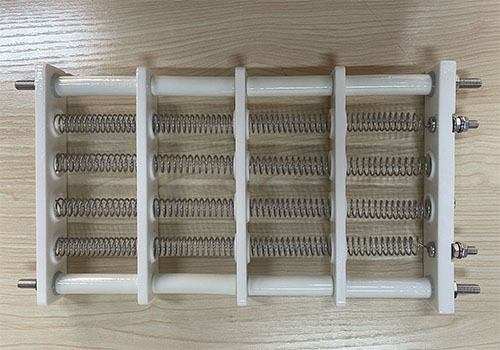

③Heating system

Heating system is mainly composed of high-power resistance wires. These resistance wires have high heating efficiency and stability with 1-3.4℃/min, and the heating elements are distributed on the back of the PV climate chamber .

④Refrigerating system

The refrigerating system includes compressor, condenser, throttling element and evaporator,these 4 components form a refrigeration cycle.

.jpg)

⑤Humidity system

Humidity system adopts steam humidification method. The low pressure steam is directly injected into the test space,humidity ranges from 20%RH to 98%RH.

⑥Control system

PID programmable color touch screen controller, network connection computer. Temperature and humidity test time, cycle times, etc. can be programmed on the controller, data can be downloaded.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia

.jpg)