In today’s competitive market, product durability is no longer optional—it's essential. Materials face constant exposure to sunlight, humidity, and temperature fluctuations that can cause fading, cracking, or premature failure. Traditional outdoor weathering tests are slow, inconsistent, and often unable to predict long-term performance accurately.

Enter the ASTM G154 UV Accelerated Aging Chamber—a state-of-the-art solution that simulates years of UV exposure and moisture conditions in a fraction of the time. By replicating real-world environmental stress in a controlled, repeatable manner, this chamber helps manufacturers ensure their products meet durability expectations while significantly reducing testing cycles.

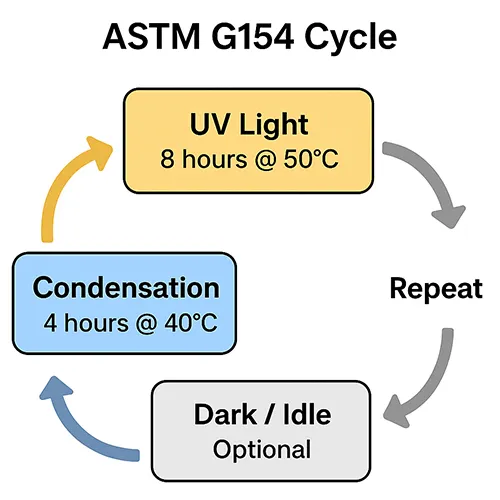

The ASTM G154 standard is internationally recognized for assessing non-metallic materials’ resistance to UV-induced degradation. It provides a scientifically validated protocol to test materials under controlled cycles of UV light and moisture exposure, ensuring reproducible and meaningful results.

UV Spectrum Simulation: UVA-340 or UVA-351 lamps reproduce the most damaging portion of sunlight that causes fading, cracking, and surface deterioration.

Temperature Cycling: Controlled exposure between 60°C and 80°C ensures realistic thermal stress.

Moisture Simulation: Condensation and water spray cycles replicate dew, rain, and humidity fluctuations.

Repeatable Protocols: ASTM G154 specifies cycle durations, intensities, and conditions for consistent lab-to-lab results.

Adhering to ASTM G154 ensures that testing results are scientifically reliable, recognized by regulatory bodies, and comparable across different labs. Manufacturers gain confidence in material performance predictions, accelerate product approvals, and reduce costly failures in the market.

uv accelerated weathering tester |

The chamber maintains stable temperature and humidity levels with minimal deviation, faithfully reproducing ASTM G154 conditions. Advanced sensors and feedback systems guarantee accurate environmental control for long-duration tests.

Equipped with UVA-340 or UVA-351 lamps, the chamber delivers uniform UV exposure across all samples. Lamp intensity can be programmed and automatically adjusted, ensuring consistent and reproducible results over thousands of test hours.

Customizable racks accommodate various sample sizes and quantities, from small panels to large components. Multiple samples can be tested simultaneously without compromising UV exposure uniformity.

With up to 120 programs and hundreds of programmable steps, users can combine UV exposure, temperature cycles, and moisture conditioning to replicate virtually any ASTM G154-compliant scenario.

The intuitive touchscreen interface and multilingual menus allow operators worldwide to set up and monitor tests with ease. Optional remote monitoring enables real-time supervision and data retrieval from anywhere, boosting lab efficiency.

All testing parameters are continuously recorded, ensuring full traceability for quality assurance, reporting, and regulatory compliance.

|  |

Model | UV-SI-260 |

Internal Dimension (mm) | 450*1170*500 |

Overall Dimension (mm) | 680*1300*1500 |

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

Distance of Specimen and lamp | 50mm |

Heating Element | Nichrome heater |

Controller | Programmable color LCD touch screen controller |

Ethernet connection, PC Link, USB | |

Water Supply System | Automatic water supply, Water purification system |

Interior Material | SUS304 stainless steel |

Evaluate color retention, gloss, cracking, and adhesion under accelerated UV exposure. Manufacturers can predict long-term performance of paints and coatings without waiting for months of outdoor testing.

Test the durability of automotive components, consumer products, and construction materials. Ensure parts withstand UV degradation, maintaining structural integrity and aesthetic quality.

Assess fading, fiber degradation, and overall weather resistance for fabrics and outdoor materials. Guarantee product longevity for demanding environmental conditions.

Determine resistance of protective housings, cables, and enclosures to UV exposure and moisture, ensuring reliable performance in real-world outdoor applications.

A leading coatings manufacturer reduced testing cycles from 12 months to just 3 weeks using our ASTM G154-compliant chamber, achieving fully validated results recognized by their quality assurance teams.

Investing in the ASTM G154 UV Accelerated Aging Chamber means more than acquiring a test device—it’s a strategic move to ensure product longevity, compliance, and market competitiveness.

By combining precise UV simulation, programmable environmental cycles, flexible sample handling, and robust data management, this chamber enables manufacturers to confidently predict material performance.

Whether you are in coatings, plastics, textiles, or electronics, adopting ASTM G154-compliant testing accelerates R&D, reduces costs, and guarantees quality in the marketplace.Our package includes a 3-year warranty, lifelong technical support, and responsive English-speaking service to ensure smooth operation.

Don’t wait for months of outdoor testing—contact us today and start delivering durable, reliable products your customers can trust.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia