Features and Benefits of IP5X Testing Chamber

1. 4mm A3 steel plate shell, and the surface is treated by spraying paint with high strength and stiffness, it can withstand various stresses and shocks during the test process, and can prevent rust corrosion.

2. Produce dust that meets the requirements of the IP5X standard size 50μm and concentration 2KG-4KG/m³, and the used dust material is dry talc powder.

3. Reliable sealing structures between the door and the chamber, each interface, and the observation window to ensure that dust will not leak into the external environment and ensure the accuracy of the test results.

4. The air circulation system is composed of fans, air ducts, vents, etc. The air generated by the fans drives the dust to circulate in the test space, so that all parts of the test sample can be fully exposed to the dust.

Specifications of IP5X Testing Chamber

Model | DI-800 | DI-1000 | DI-1500 | DI-2000 |

Internal Dimension (mm) | 800*1000*1000 | 1000*1000*1000 | 1000*1500*1000 | 1000*2000*1000 |

Overall Dimension (mm) | 1040*1450*1960 | 1330*1450*1960 | 1330*1950*1990 | 1330*2450*1990 |

Useful Volume (L) | 800 | 1000 | 1500 | 2000 |

Temperature Range | Ambient ~ +50℃ |

Humidity Range | < 30% RH |

Normal Wire Diameter | 50um |

Nominal Width of a Gap Between wires | 75um |

Fight Time | 0 ~ 99H59M |

Blowing Time | 0 ~ 99H59M |

Specimen Power Outlet | Dust-proof socket 16A |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Standard Configuration | Sample shelf, dust wiper, talcum powder(5kgs) |

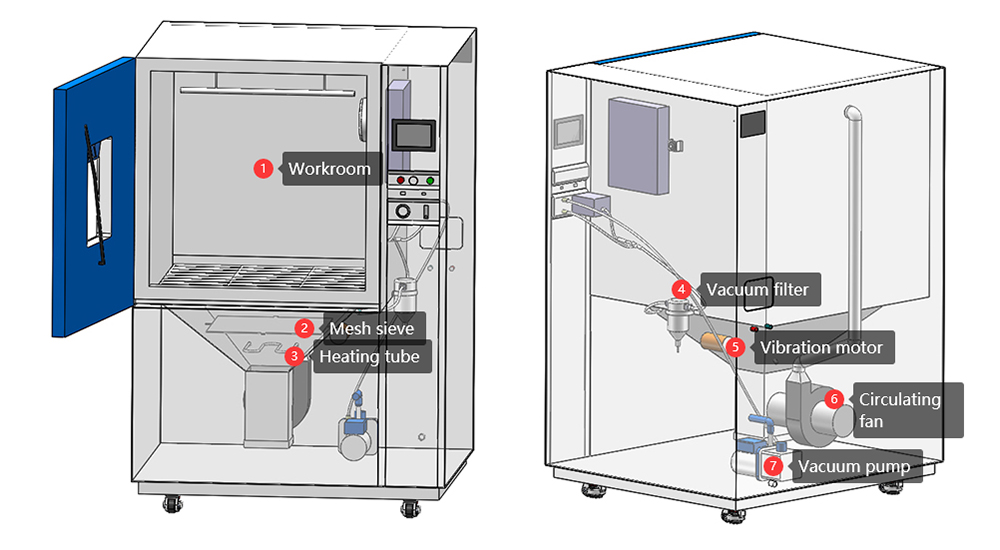

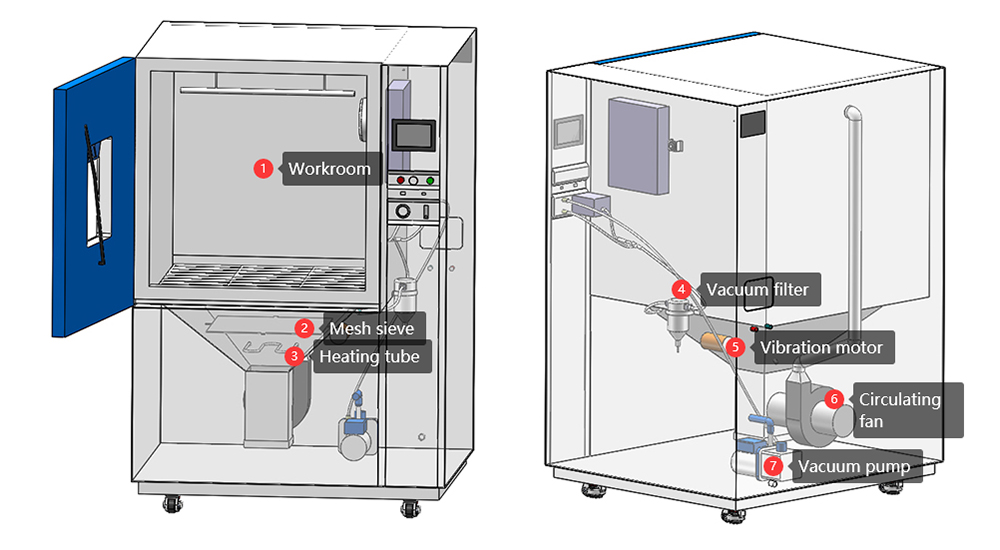

Configuration of IP5X Testing Chamber

① Workroom | Made of SUS304,corrosion-resistant and easy to clean. Built-in lighting and hanging rack for convenient sample arrangement and observation. The O-shaped vertical circulation system ensures more uniform dust distribution and enhances test consistency.

|  |

② Mesh sieve | Nominal diameter of dust is 50 μm. Prevent large particles from fall out the duct. |  |

③ Heating tube | The temperature control range is set to 50℃ to prevent dust from getting damp and clumping, ensuring a continuous and stable testing process.

|  |

④ Vacuum filter | Filter fine particles in the air to prevent them from entering the vacuum pump and extend the service life of the equipment. |  |

⑤ Vibration motor | Simulate the actual vibration environment, shake off the adhering dust, and improve the authenticity of the test. |  |

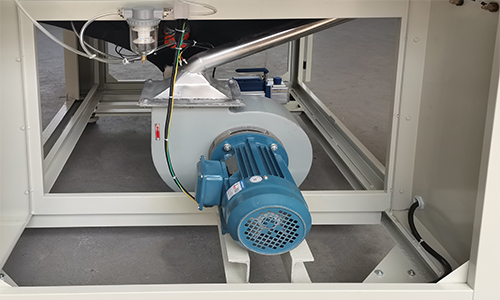

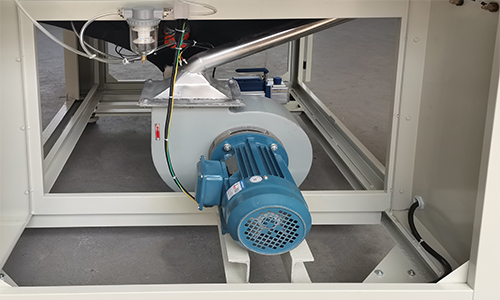

⑥ Circulating fan | Closed alloy low noise motor, multi-blade centrifugal fan, etc., generate circulating air to drive dust flow. |  |

⑦ Vacuum pump | The low-noise alloy motor and multi-blade fan form a strong airflow, driving the dust to be evenly suspended. |  |

...................................................................................................................................................................................................................................................................

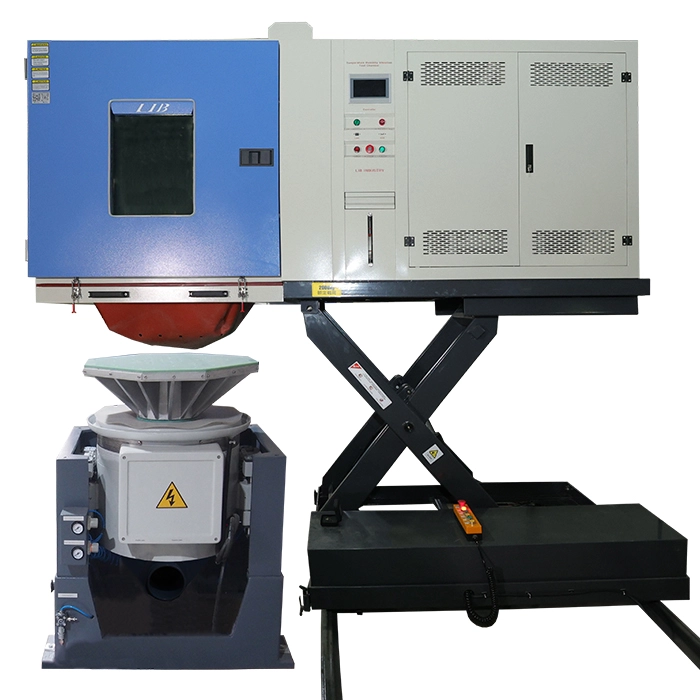

Features and Benefits of IPX5 Testing Chamber

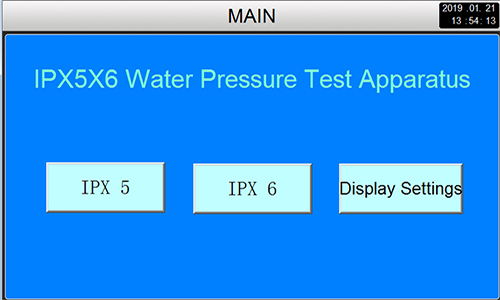

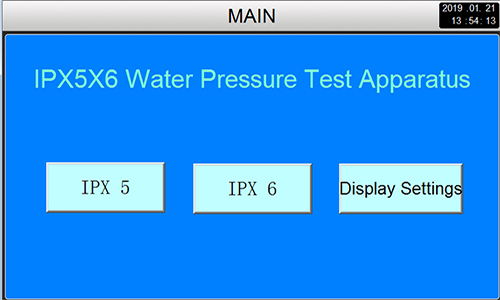

1. During the test, the distance from the sample to the spray nozzle is 2.5m~3m, the inner diameter of the spray nozzle is 6.3mm, and the nozzle can spray the sample at different angles and the water flow rate is stable with 12.5L/min (750L/h).

2. Transparent observation window, made of tempered glass and other high-strength materials, with good transparency and impact resistance, convenient for operators to observe the test sample during the test process.

3. Good sealing structure between the door and the chamber, the interface, the observation window and other parts of the test chamber to ensure that the water will not leak into the external environment during the test.

4. A complete set of automatic water intake and water circulation system, with water filtration, can filter out 0.03mm diameter particles, there is a drain in the work room, can save water.

Specifications of IPX5 Testing Chamber

Model | R6K-1200 |

Internal Dimensions (mm) | 1000*1200*1000 D*W*H |

Overall Dimensions (mm) | 1150*3550*2100 D*W*H |

Interior Volume (L) | 1200 |

Parameter | Testing Platform Diameters | 600mm |

Testing Platform Speed | 5±1 r.p.m |

Turntable loads | 50kgs |

Testing Platform Height | 200-400 mm (adjustable) |

IPX6K | Internal Diameter of Nozzle | 6.3mm |

Water Flow Rate | 75 L/min +/- 5% |

Water pressure | 1000 Kpa |

Distance fromWater Spraying to Specimens | between 2.5 m and 3 m. |

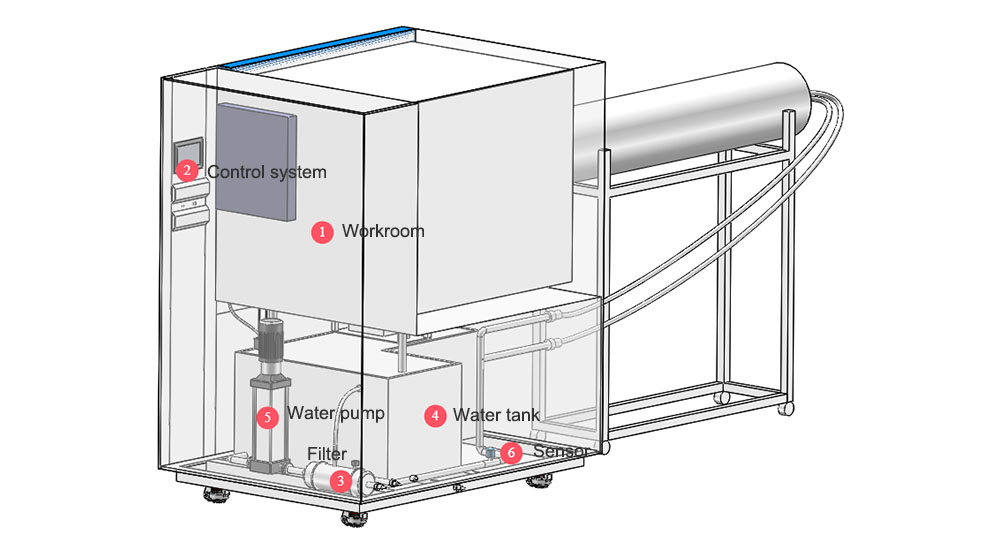

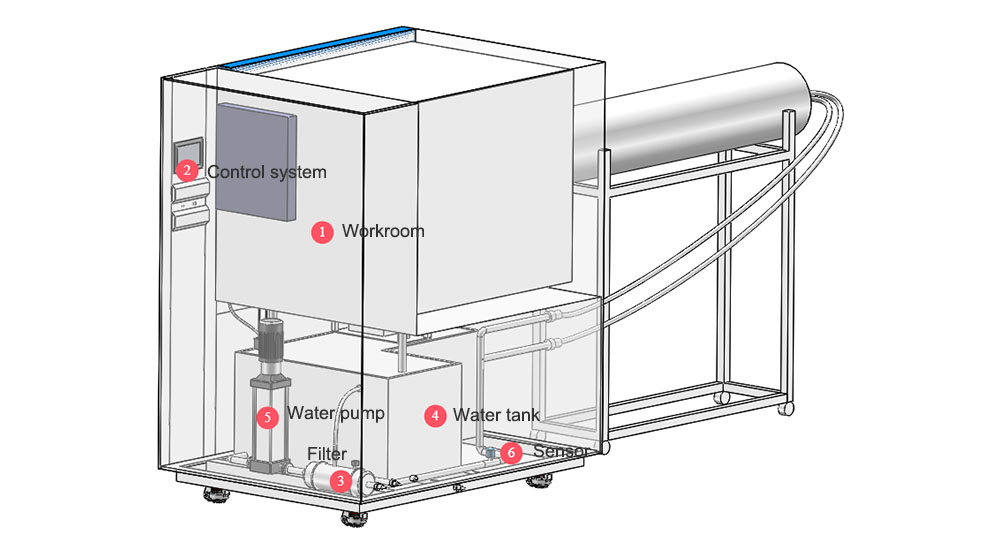

Configuration of IPX5 Testing Chamber

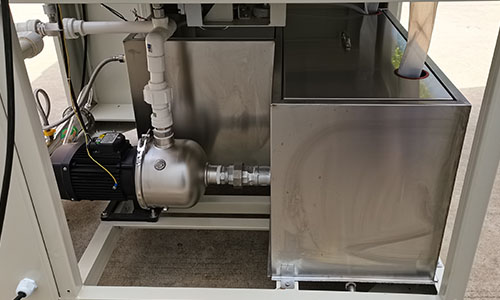

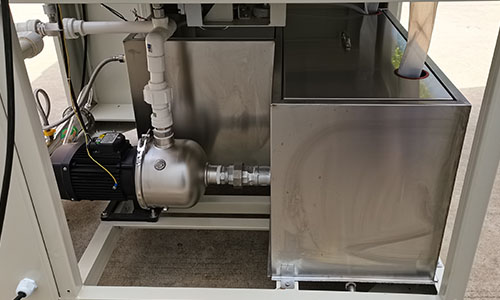

① Workroom | SUS304 stainless steel, corrosion-resistant and easy to clean. The dual-nozzle design supports multi-angle water spraying ranging from 2.5 to 3 meters. Combined with a variable-speed turntable, it enables all-round spray testing.

|

|

② Control system | The PLC precisely controls parameters such as time, water flow, spray Angle and rotational speed, with real-time display. The operation is convenient and the results are reliable. |  |

③ Filter | The filtration accuracy is 0.03MM diameter particles to ensure the cleanliness of the water. |  |

④ Water tank | The float valve monitors the water level in real time to prevent dry running due to water shortage and extend the service life of the equipment. |  |

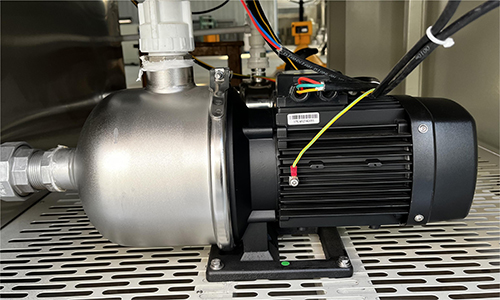

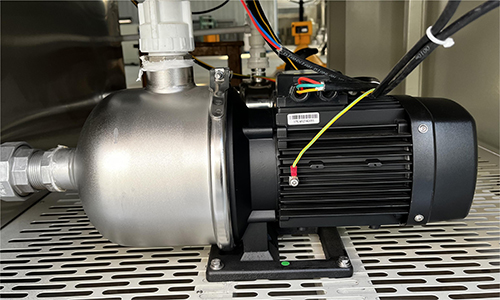

⑤ Water pump | Continuously provide flow and pressure that meet the IPX5 standard to ensure a strong and uniform spray. |  |

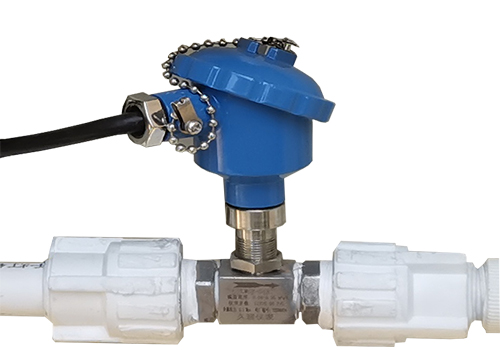

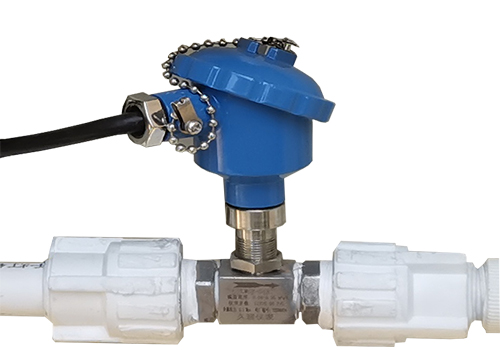

⑥ Sensor | For precise control of water flow and pressure, to ensure that the water flow is stable within the standard range of 12.5±0.625 (L/min). |  |

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia