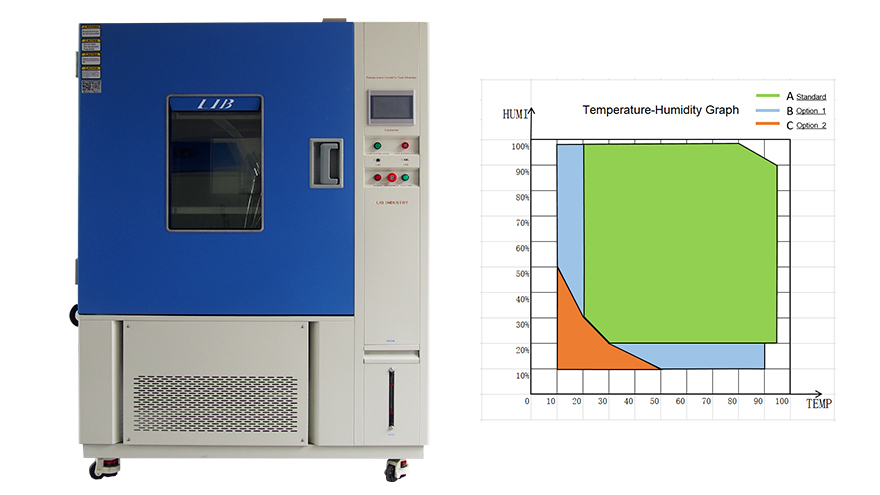

In industries where precision and reliability are non-negotiable—such as aerospace, electronics, automotive, and materials testing—controlled environmental conditions are critical. To meet these demanding requirements, LIB has environment controlled chambers designed to simulate a wide range of temperature and humidity scenarios with exceptional accuracy.

This article explores three foundational components of LIB environment controlled chambers : the internal workroom structure, the humidification mechanism, and the refrigeration system.

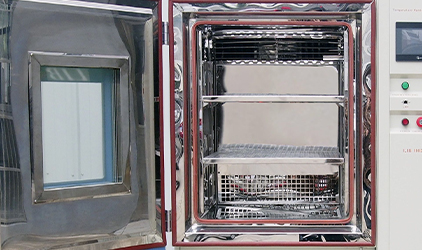

The internal chamber (workroom) is the primary space where specimens are exposed to controlled environmental conditions. LIB chambers adopt a stainless steel SUS304, which ensures corrosion resistance and easy cleaning. The outer shell is made of powder-coated galvanized steel, providing durability and aesthetic value.

To maintain insulation and reduce energy loss, the chamber is filled with high-density polyurethane foam insulation, with a thickness of 100 mm. The door features a multi-layer silicone sealing strip that ensures airtightness, reducing the chance of condensation or heat leakage.

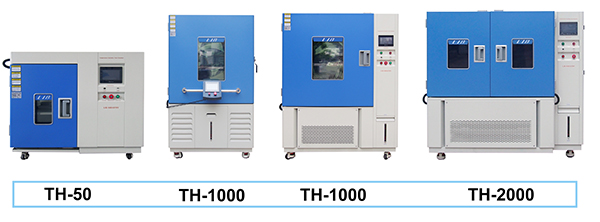

Inner dimensions: customizable, standard size options include 50L,80L,100L,225L,500L,800L,1000L and more.Observation window with double-layer vacuum glass

Interior LED lighting for visibility during testing

Removable shelves for flexible test space usage

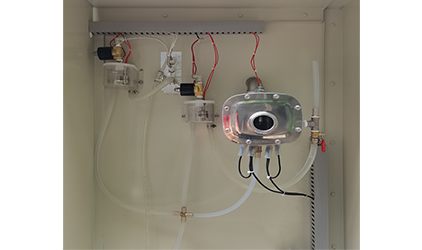

Precise humidity control is crucial for many environmental tests. LIB uses a direct steam humidification system in its chambers, which offers fast response and high accuracy.

The humidifier is equipped with:

Stainless steel electric steam generator

PID-controlled proportional valve to maintain stable RH

Humidity range: from 20%RH to 98%RH

Humidity deviation: ±2.5%RH (under stable conditions)

The water used in the system is filtered and softened to prevent scale formation, which can reduce maintenance needs and prolong system life.

Rapid humidity rise time

Automatic water refill and level protection

Temperature control in LIB environment controlled chambers is achieved through a mechanical refrigeration system using environmentally friendly refrigerants, depending on the temperature range.

LIB adopts a two-stage cascade refrigeration system for ultra-low temperature models, enabling the chamber to reach -70°C quickly and stably. For standard models, a single-stage system can manage temperatures ranging from -20°C / -40°C to +150°C.

Fully enclosed French Tecumseh compressors

Danfoss expansion valves for precise refrigerant control

Air-cooled or water-cooled condenser options

Intelligent defrosting to ensure performance under high humidity

Temperature fluctuation: ±0.5°C

Temperature uniformity: ±2.5°C

Cooling rate: 1°C/min (standard, faster upon request)

LIB is committed to high-quality engineering and user-oriented customization. With over 16 years of experience, LIB environment controlled chambers are widely used in electronics, automotive, aerospace, materials, and research laboratories. All chambers undergo strict quality control and come with 3 years warranty and lifetime technical support.

Remote control and monitoring options

On-site installation and training

24/7 online technical assistance

Fast spare parts delivery service

The structure, humidification, and refrigeration systems are critical to the performance and reliability of an environmental test chamber. Whether you are testing electronics, coatings, or composite materials, LIB provides dependable solutions tailored to your needs.

Contact LIB today inquiry@libtestchamber.com to learn more about our temperature humidity test chambers or request a customized solution for your testing requirements.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia