In industrial testing, one phrase is often repeated: “1000 hours of salt spray equals 10 years of outdoor durability.”

It’s catchy, but dangerously misleading. Salt Spray Testing (SST) offers a single, continuous environment. Real corrosion is not constant fog—it is a complex rhythm of rain, sun, temperature swings, humidity, and drying.

This is where the Cyclic Corrosion Test Chamber (CCT) reshapes the conversation. Instead of counting hours, CCT helps manufacturers predict real-life durability by recreating the same failure mechanisms seen in service environments.

Salt spray has been used for decades because it is simple and fast. However, it:

Provides only one stress factor (constant NaCl fog).

Does not account for temperature changes, condensation, or UV exposure.

Produces failure modes that often do not correlate with field service conditions.

In other words, surviving 1000 hours in SST does not guarantee survival after two winters on a salted highway or five years in a marine climate.

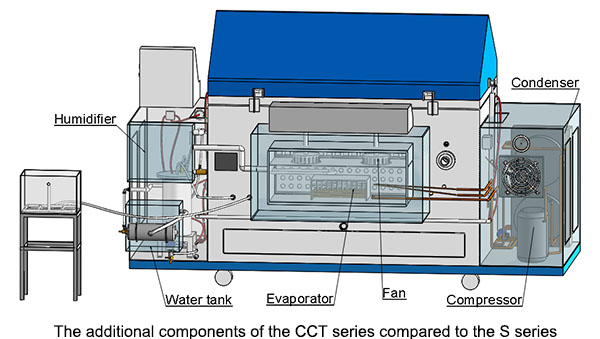

A Cyclic Corrosion Test Chamber alternates between multiple environments:

Salt fog deposition (to replicate marine or de-icing salt).

High-humidity condensation (mimicking morning dew or rainfall).

Drying and heating phases (accelerating crack propagation).

Cooling cycles (simulating day-to-night transitions)

This sequence recreates real-world stress patterns, making the data meaningful. Instead of hours, engineers look at failure progression—rust creep, blistering, coating delamination—that mirrors outdoor exposure.

CCT is not guesswork; it is codified in global standards that align laboratory tests with outdoor field performance:

SAE J2334 – Widely used in North America for automotive materials.

ISO 16701 – Focused on natural-like corrosion for automotive and metals.

VDA 233-102 – German automotive standard for corrosion resistance.

By meeting these standards in a controlled chamber, manufacturers can ensure their coatings and assemblies perform reliably over years of service.

Consider an automotive body panel:

Under SST: It may resist red rust for 1000 hours, leading engineers to assume long-term durability.

Under CCT (SAE J2334 cycles): Within weeks, micro-cracks appear, and rust creeps along cut edges.

These patterns match what vehicles show after two to three winters on salted roads.The takeaway: 1000h in CCT ≈ 2–3 years of outdoor exposure, not because of a direct equation, but because the failure mode is the same.

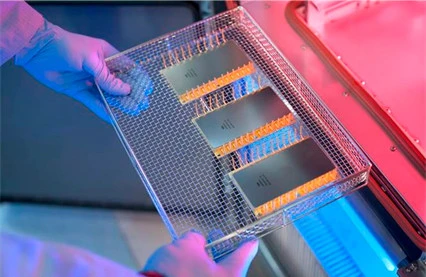

LIB Industry designs chambers that transform testing hours into realistic durability predictions. Their Cyclic Corrosion Test Chambers (models SC-010, SC-016, SC-020) combine precision control with compliance to global standards.

Parameter | Specification |

Temperature Range | +10 °C to +90 °C (fluctuation ±0.5 °C) |

Humidity Range | 30%–98% RH (deviation +2 / −3%) |

Salt Fog Deposition Rate | 1–2 mL / 80 cm²·h (ASTM B117 compliant) |

Chamber Sizes | 780 L, 1,280 L, 1,800 L – adaptable to small components or full body panels |

Control System | Touchscreen interface, fully programmable cycles, Ethernet remote monitoring |

Construction | FRP inner chamber with anti-corrosion design, precision atomizing tower, refrigeration, multiple safety protections |

This combination ensures accurate simulation of real-world conditions and reproducible results across test cycles.

The critical point is this: durability is not a simple conversion of hours into years. Instead, it is about replicating the environmental stresses that drive real-world failures.

With CCT chambers, engineers can:

Compare materials and coatings under equivalent stress.

Detect early signs of degradation aligned with field experience.

Build predictive models by linking test data with natural exposure studies.

This is the scientific way to replace the outdated “1000 hours = 10 years” shortcut.

Manufacturers across automotive, marine, aerospace, and electronics industries turn to LIB because the chambers are:

Accurate – tight temperature and humidity tolerances.

Versatile – programmable cycles for multiple standards.

Scalable – chamber volumes from 780 L to 1,800 L.

Reliable – robust FRP construction, safe operation, long service life.

And with service points in the USA, Canada, UK, and Malaysia, LIB provides ongoing support, from installation to lifetime maintenance.

“1000 hours equals 10 years” is a myth that oversimplifies corrosion science. True durability comes from reproducing failure mechanisms, not chasing hours.

The Cyclic Corrosion Test Chamber is the tool that bridges the lab and the field—delivering results engineers can trust.

Ready to translate test data into real-life durability?

Explore LIB’s Cyclic Corrosion Test Chambers and consult LIB engineers inquiry@libtestchamber.com to design a testing program tailored to your products and environments.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia