Many metal surfaces appear flawless, yet hidden beneath the coating, corrosion may already be silently progressing. This phenomenon, known as filiform corrosion, manifests as thread-like filaments under the paint or protective layer, primarily affecting aluminum and steel substrates. Unlike uniform or pitting corrosion, filiform corrosion advances in a worm-like pattern beneath coatings, often undetectable until significant damage occurs.

For manufacturers in automotive, aerospace, and electronics industries, maintaining coating integrity is crucial. LIB Industry provides a comprehensive filiform corrosion tester solution that integrates a filiform corrosion tester and a constant temperature & humidity chamber, offering a precise and repeatable method to reveal hidden corrosion risks before they compromise product reliability.

Filiform corrosion requires specific environmental and substrate conditions:

High relative humidity: Above 75%

Moderate temperatures: 20–40°C

Presence of soluble salts: Chlorides or sulfates

Oxygen access beneath permeable coatings

Electrochemical differences between anodic and cathodic regions under the coating drive the corrosion filaments, gradually degrading both the metal and coating adhesion. Understanding these conditions is essential for designing effective corrosion tests and protective coatings.

Filiform corrosion is often invisible to the naked eye in early stages.

When visible, it appears as:

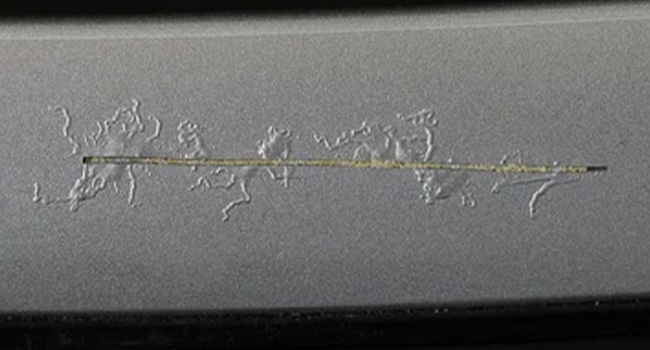

Thin, thread-like filaments beneath the coating

Light brown or white “spider web” patterns

Linear or directional spread originating from coating defects

Early detection is critical because the corrosion may already have compromised the substrate long before it is noticeable externally. Laboratory testing using controlled environments is the only reliable method to assess filamentous corrosion.

LIB Industry’sfiliform corrosion tester solution integrates two devices to replicate the complete corrosion process: - Primary Device: Salt spray chamber – activates corrosion at coating defects. - Auxiliary Device: Constant temperature & humidity chamber – maintains a stable environment for filament growth and propagation.

Purpose: Initiates corrosion on scribed or defected panels.

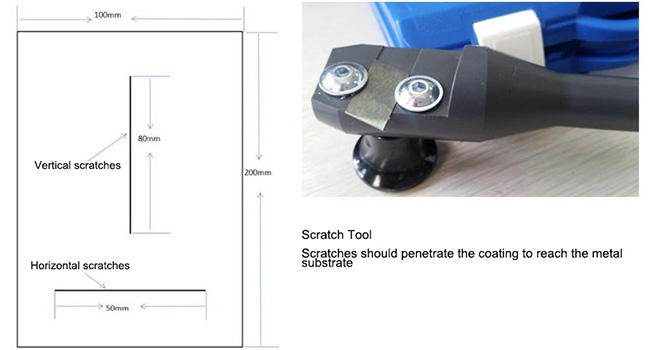

Sample preparation: Coated metal panels scribed with 1 mm lines to simulate defects.

CASS solution composition: NaCl 50 g/L,CuCl₂ 0.26 g/L,pH 3.1–3.3 (adjusted with glacial acetic acid)

Sedimentation volume: 80 cm², 1–2 mL/h

Temperature: 50°C

Exposure time: 6 hours

Standard: SAE J2635

Name | Salt spray chamber | |||

Model | S-150 | S-250 | S-750 | S-010 |

Interior Volume (L) | 110 | 320 | 410 | 780 |

Temperature Range | Ambient ~ +60°C | |||

Temp. Fluctuation | ±0.5°C | |||

Temp. Deviation | ±2.0°C | |||

Humidity Range | 95%–98% RH | |||

Salt Fog Deposition | 1–2 mL/80cm²·h | |||

Spray Type | Continuous / Periodic | |||

| ||||

Key Advantages of the Filiform Corrosion Tester :

Precision Control System – Temperature ±0.5°C, Humidity ±2% RH ensures repeatable, reliable test conditions

Corrosion-Resistant Build – Upgraded fiberglass-reinforced plastic inner workspace for durability

Flexible Test Capacity – Multiple sample holders for 2D and 3D samples, supporting simultaneous tests

Standard Compliance – ASTM B117, ISO9227, SAE J2635

Samples move to the constant temperature & humidity chamber for controlled exposure.

Parameters:

Temperature: 65 ±1°C

Relative Humidity: 85 ±3% RH

Inclination Angle: 45°

Air Circulation: 6–24 m/min

Total Exposure Time: 672 hours

Inspection Interval: Every 168 hours

Handling During Inspection: Maximum 15 minutes outside the constant temperature and humidity chamber

Observation & Evaluation: Filament growth is measured for length, density, and spread direction via visual assessment or digital image analysis.

Name | Temperature and humidity chamber | |||

Model | TH-100 | TH-225 | TH-500 | TH-1000 |

Interior Volume | 100L | 225L | 500L | 1000L |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ | |||

Temperature Fluctuation | ± 0.5 ℃ | |||

Temperature Deviation | ± 2.0 ℃ | |||

Humidity Range | 20% ~ 98% RH | |||

Humidity Deviation | ± 2.5% RH | |||

Cooling Rate | 1 ℃ / min | |||

Heating Rate | 3 ℃ / min | |||

| Interior Material | SUS304 stainless steel | |||

| ||||

Filiform corrosion often begins at minor coating defects, such as scratches, pinholes, or exposed edges. Once initiated, it spreads along the substrate, weakening adhesion and potentially leading to large-scale coating failure.

Industries where coating durability is critical face substantial risks:

- Automotive: Aluminum body panels exposed to humid, salty environments may develop corrosion beneath the paint, causing unsightly blemishes or structural compromise.

- Aerospace: Aircraft skin coatings require rigorous protection; hidden filiform corrosion could affect surface integrity under high-humidity, marine-influenced environments.

- Electronics: Protective coatings on circuit boards must remain intact; filiform corrosion can lead to premature device failure.

Traditional corrosion tests, such as standard salt spray alone, cannot fully reproduce the unique conditions that trigger and propagate filiform corrosion. This is where LIB Industry’s dual-system solution provides unmatched reliability.

Filiform corrosion may start from a single scratch but can cause significant hidden damage beneath the coating. With LIB Industry’s dual-system filiform corrosion tester, you can simulate the entire process—from initiation in a salt spray chamber to controlled filament growth in a constant temperature & humidity chamber—with unmatched precision and repeatability.

Contact LIB Industry inquiry@libtestchamber.com with your testing requirements

Receive a custom quotation and test plan within 1–3 hours

Enjoy global service points, lifetime technical support, and ready stock for fast delivery

Ensure your coated products remain durable and reliable—LIB Industry makes corrosion testing effortless, accurate, and actionable.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia