Pre-painted galvanized iron (PPGI) is widely used in construction, home appliances, steel structures, and industrial enclosures. While its coated surface provides initial corrosion protection, real-world failures still occur frequently, especially in coastal, humid, or polluted environments.

Typical customer complaints include:

Coating blistering after short outdoor exposure

Rapid red rust propagation from cut edges or scribed areas

Premature edge corrosion despite acceptable coating thickness

In many cases, the root cause is not the coating formulation itself, but an inaccurate or unstable salt spray test process.

ASTM B117 neutral salt spray testing is globally recognized as the baseline corrosion resistance evaluation method for coated steel products such as PPGI. However, the reliability of ASTM B117 results depends entirely on how precisely and consistently the test is executed.

That is where a professional, industrial-grade salt spray test chamber from LIB industry becomes essential.

ASTM B117 is not simply about spraying salt solution. It is a process-driven standard with strict requirements for specimen positioning, spray generation, temperature control, and long-term stability.

| Item | Specification |

|---|---|

| Chamber temperature | 35 ±1°C |

| Air saturator temperature | Compliant with NSS requirements |

| Salt solution concentration | 5% NaCl |

| Spray mode | Continuous / Intermittent |

| Deposition rate | 1.0–2.0 mL / 80 cm² / h |

LIB industry salt spray test chambers are engineered around this full process to ensure accuracy, repeatability, and confidence in every test.

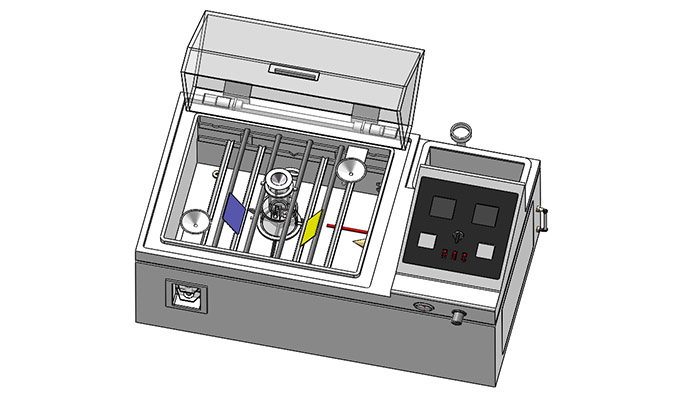

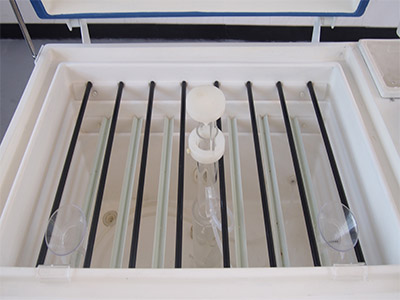

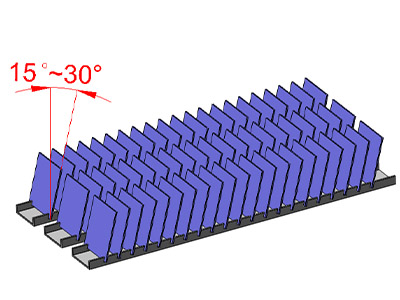

According to ASTM B117, test specimens must be positioned at an angle of 15° to 30° from vertical to prevent condensate droplets from falling directly onto the surface and creating non-standard corrosion patterns.

How LIB industry supports this step:

Standard V-shaped and U-shaped specimen racks designed specifically for flat panels such as PPGI

Continuously adjustable angles to fully comply with ASTM B117 requirements

Corrosion-resistant rack materials that remain stable during long-term exposure

Optimized spacing to ensure uniform salt fog deposition on every panel

| |

Round Bar + V-Groove Sample Holder |  Insert-Type Sample Holder |

This ensures that all PPGI samples experience identical exposure conditions, forming the foundation for valid comparison.

ASTM B117 specifies:

5% NaCl salt solution

Deposition rate of 1.0–2.0 mL / 80 cm² / hour

Continuous, uniform, and uninterrupted fog generation

LIB industry salt spray test chamber advantages:

High-precision quartz spray nozzles

Uniform atomization

No crystallization or clogging during long-duration tests

Adjustable spray system

Fine control of fog output

Stable deposition rate throughout extended test cycles

Standard collection funnel and cylinder support

Easy verification of deposition rate before and during testing

| |

|

|

| quartz spray nozzles | Brine Mixing System |

A 500-hour salt spray test only has value if every single hour remains within ASTM B117 limits—and that is exactly what LIB industry chambers are designed to deliver.

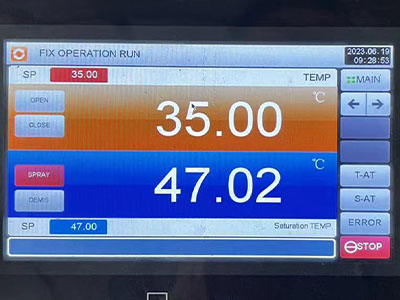

ASTM B117 requires the chamber temperature to be maintained at 35 ±1°C, while the compressed air used for atomization must be properly humidified.

LIB industry’s precision control system includes:

Intelligent PID temperature control

Real-time adjustment to minimize fluctuations

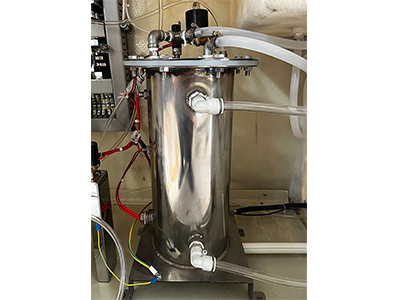

Air saturator tower based on Henry’s Law

Ensures fully humidified air before salt fog generation

Prevents salt concentration shifts caused by dry air

Multi-side heating and optimized airflow design

Uniform temperature distribution throughout the chamber

Eliminates edge effects and localized over-corrosion

|

|

This level of control ensures high repeatability across multiple test batches.

PPGI corrosion evaluation often requires 240, 500, or even 1000 hours of continuous salt spray exposure.

LIB industry industrial-grade reliability includes:

Automatic and manual water replenishment options

Low water level alarms to prevent test interruption

Support for extended unattended operation

Comprehensive safety protection:

Over-temperature protection

Water shortage protection

Overload and pressure abnormality protection

The result is a salt spray test chamber that does not merely “run,” but runs stably for the entire duration of demanding corrosion tests.

LIB industry salt spray test chambers are purpose-built solutions optimized for ASTM B117 testing and PPGI corrosion evaluation, rather than generic laboratory equipment.

Model | S-150 | S-250 | S-750 | S-010 |

Interior Volume (L) | 110 | 320 | 410 | 780 |

Temperature Range | Ambient ~ +60 ℃ | |||

Temperature Fluctuation | ± 0.5 ℃ | |||

Temperature Deviation | ± 2.0 ℃ | |||

Humidity Range | 95% ~ 98% RH | |||

Salt Fog Deposition | 1~2ml / 80cm2 · h | |||

Spray Type | Continuous / Periodic | |||

Salt Fog Collected | Fog collector and fog measure cylinder | |||

Air Preheating | Saturated air barrel | |||

Spraying System | Atomizer tower and Spray nozzles | |||

Controller | PID controller | |||

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection | |||

Material | Glass fiber reinforced plastics | |||

| Standard Configuration | 6 round bars and 5 V-shaped grooves | |||

.jpg) | ASTM B117 Salt Spray Environmental Test Chamber Salt Spray Cyclic Corrosion Tester Salt Fog and SO2 Corrosion Chamber | |||

One-piece P.P or advanced PVC chamber construction

Excellent resistance to acid, alkali, heat, and aging

Transparent, impact-resistant lid

Continuous visual monitoring of corrosion behavior

Water-sealed structure

Prevents salt fog leakage

Protects surrounding laboratory equipment

7-inch full-color touchscreen controller

One-touch ASTM B117 test setup

Continuous and intermittent spray modes

Test data recording and export capability

Optional remote monitoring and communication interfaces

Suitable for laboratory and factory quality systems

Dedicated panel specimen rack system

One-touch defogging function after test completion

Prevents salt fog escape when opening the chamber

Modular internal layout

Easy maintenance and reduced operating costs

Absolutely. The chamber is equipped with V-shaped and U-shaped specimen racks designed for flat metal panels such as PPGI. Adjustable specimen angles (15°–30°) allow accurate evaluation of cut-edge corrosion and scribe creep, which are critical indicators for coated steel products.

Yes. The LIB industry salt spray chamber supports extended continuous testing (240 h, 500 h, 1000 h) with:

Automatic and manual water replenishment

Low water level alarms

Comprehensive safety protections

This allows reliable unattended operation without compromising test integrity.

In addition to ASTM B117 (NSS), LIB industry also provides solutions for:

ISO 9227

Customized salt spray test requirements

Advanced corrosion testing systems such as cyclic corrosion testing (CCT) upon request

This flexibility allows users to expand testing capability as standards or product requirements evolve.

Looking to verify your ASTM B117 testing process?

Need a salt spray test chamber optimized for PPGI applications?

Global technical support and spare parts

3-year comprehensive warranty covering core systems

Lifetime technical support provided by senior engineers

Rapid remote diagnostics and response within 1–3 hours

Contact LIB industry today inquiry@libtestchamber.com for expert consultation or to schedule a live equipment demonstration.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia