Why Choose LIB Industry Weatherability Xenon Arc Test Instrument?

1. True Solar Simulation: Laboratory-grade reproduction of the full solar spectrum.

2. Lower Energy Consumption:The xenon arc lamp has a lifespan of ≥ 1600 hours, reducing the cost of consumables.The water-cooling mode has lower energy consumption and higher operating efficiency.

3. High-Precision Reliability: Uniform irradiance, controlled humidity, and temperature for repeatable results.

4. Material Versatility: Suitable for polymers, coatings, automotive interiors, metals, and construction materials.

5. Customizable Architecture: Adjustable workroom dimensions, holder configurations, and spectral emphasis.

6. Long-Term Support: 3-year warranty with lifetime technical assistance ensures uninterrupted operation.

Key Technical Parameters of Weatherability Xenon Arc Test Instrument

Model | XL-S-750 | XL-S-500 |

Internal Dimension (mM) | 950*950*850 mm | 500*600*700 mm |

Overall Dimension (mM) | 1400*1400*1950 mm | 1000*1140*1920 mm |

Specimen Holder Size(mm) | 95*200 | / |

Specimen Capacity | 42pcs | / |

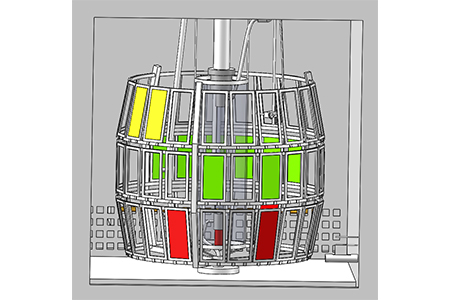

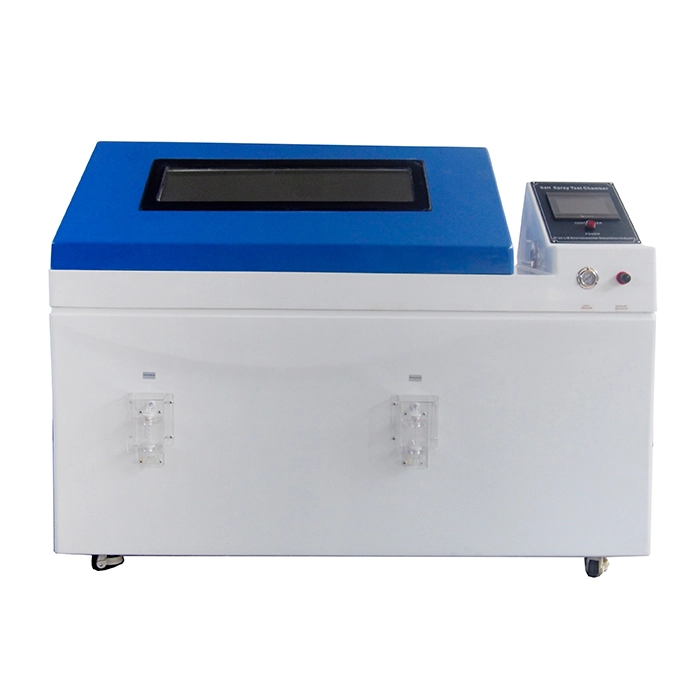

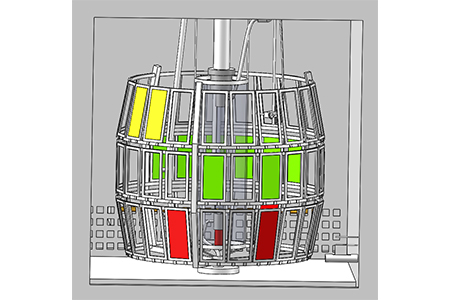

Chamber Type | Rotating Holder | Flat shelf |

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Water supply system | Automatic water supply, Water purification system |

Radiometer | UV Radiometer, Tolerance: ±5% |

Cooling System | Mechanical compression refrigeration system |

Engineering Highlights of Weatherability Xenon Arc Test Instrument

Workroom Design

| Material: SUS304 stainless steel, corrosion-resistant, and easy to maintain. Thermal Control: Maintains stable conditions from ambient to 100 °C with ±0.5 °C precision. Airflow Optimization: Internal airflow minimizes hot/cold spots; reflective surfaces enhance uniform light distribution.

|

|

Specimen Holder and Exposure Configuration | Adjustable Holder: Supports rotating and flat configurations for uniform irradiance. Customizable Size: Standard holder 95 × 200 mm,3 layers; multiple tiers available for expanded capacity. Even Exposure: Rotational control ensures all sample surfaces receive consistent irradiation.

|

|

Xenon Lamp System | Full-Spectrum Solar Simulation: UV–VIS–IR output replicates natural sunlight. Stable Irradiance: 35–150 W/m² maintained with ±0.5 % precision for consistent test results. Lamp Longevity: ≥1600 hours; easily replaced for continuous operation. Optional Spectrum Emphasis: Extended UV or IR modules for targeted degradation studies.

|  |

Control and Data Management | Advanced PID Controller: Programmable cycles for irradiance, temperature, humidity, and spray patterns. Remote Access & Monitoring: Real-time operation control and alert notifications. Data Export: USB/Ethernet for experiment logs, traceability, and quality verification. Custom Test Programs: Preloaded or user-defined cycles tailored to product-specific aging profiles.

|  |

Precision Irradiance Measurement | Integrated Radiometer: Measures in real-time to maintain uniform exposure across samples. Multiple Sensors: Allows simultaneous monitoring at 340 nm and 420 nm wavelengths. Feedback Control: Automated lamp adjustment ensures compliance with ASTM G151/G155 requirements.

|  |

Expert Tips – Weatherability Xenon Arc Test Instrument

Q1: What is the minimum temperature achievable in the xenon arc test equipment?

The xenon arc test equipment can reach -70 °C. This is made possible with high-thermal-resistance xenon lamps, enhanced refrigeration, and specialized black panels and radiometers—ensuring accurate, repeatable results under extreme conditions.

Q2: What is the maximum rotation speed of the xenon turntable?

The rotating holder operates at up to 7 r/min, guaranteeing uniform exposure and consistent, reliable test results for all samples.

Q3: What is the difference between BPT and BST?

BPT (Black Panel Temperature): Measures metallic samples with a black-painted metal plate.

BST (Black Standard Temperature): Measures non-metallic surfaces with a black-painted insulated plastic plate.

Difference: Varies by material; LIB industry can customize calibration for precise, traceable measurements.

Contact LIB Industry Today

Accelerate weathering studies with confidence using the weatherability xenon arc test instrument from LIB industry. Contact us today to discuss your project specifications within 1~3 hours:

Email:inquiry@libtestchamber.com

Fast Production | ISO/ASTM Compatibility | Custom Engineering | 3-Year Warranty & Lifetime Support

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia