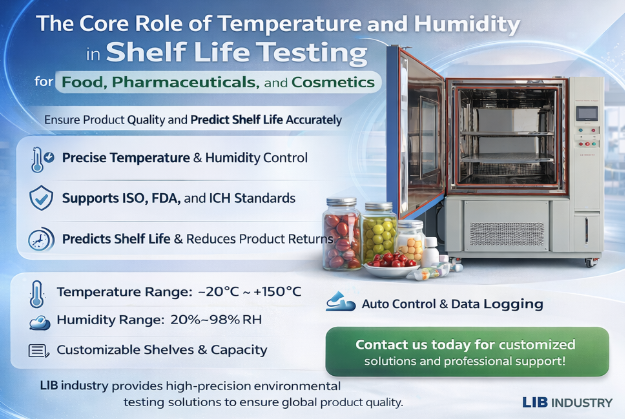

Maintaining product quality throughout its shelf life is a major challenge for the food, cosmetics, and pharmaceutical industries. Consumers demand safe, effective products, while regulators enforce strict compliance standards.

Fluctuations in temperature, high humidity, and improper storage can accelerate spoilage, degrade active ingredients, or reduce cosmetic efficacy. Improperly stored cosmetics may lose significant potency in weeks, food products can spoil or become contaminated, and biologic pharmaceuticals are particularly sensitive to temperature changes.

These issues often lead to customer complaints, returns, costly recalls, and brand damage. Companies need reliable methods to predict shelf life, optimize formulations, and validate packaging.

Temperature and Humidity Chambers offer a solution, creating controlled environments that simulate real storage conditions. By accurately replicating temperature and humidity changes, these chambers provide actionable data to improve product stability and safeguard brand reputation.

●Customer Insight:

A leading laboratory in Singapore recently integrated LIB industry chambers for cosmetics shelf life testing. The lab reported that the system performed flawlessly, enabling accurate and consistent testing, while the responsive support team ensured smooth operation and ongoing reliability. This success underscores the practical value of high-quality temperature and humidity chambers in real-world applications.

Selecting a high-performance chamber requires attention to international standards and industry regulations, as these directly affect the credibility of test results. LIB industry chambers are designed to meet the strictest requirements:

ISO 9001 / ISO 22000 – Ensuring consistent food safety and quality management

ICH Q1A – Stability testing for pharmaceuticals to predict product shelf life

ASTM D4332 – Packaging and food durability evaluations

FDA / GMP Guidelines – Ensuring compliance for both testing and regulatory audits

Adhering to these standards is more than compliance; it is risk mitigation. Accurate, validated testing prevents product failures, supports regulatory submissions, and enhances consumer confidence.With regulatory compliance ensured, the next critical factor is performance, precision, and usability—what sets LIB industry chambers apart in the market.

LIB industry provides a full line of Temperature and Humidity Chambers, including models TH-50,TH-80,TH-100 ... and TH-1000, engineered specifically for food, cosmetic, and pharmaceutical applications. These chambers are built to deliver precision, reliability, and operational convenience, transforming stability testing into a streamlined, efficient process.

Environmental Chamber For Temperature and Humidity Test | |

| temperature and humidity chamber temperature humidity environmental control chamber |

Key Features & Customer Benefits:

High-Precision Control:

Advanced PID control with SSR drives maintains temperature deviations within ±0.5°C and humidity deviations within ±2% RH. Consistent and repeatable testing conditions reduce variability in shelf life predictions, giving manufacturers confidence in decision-making.

Flexible & Customizable Interior:

Adjustable stainless steel racks support diverse product types and sizes, from vials, jars, and bottles to bulk food packages. This flexibility allows simultaneous multi-sample testing, maximizing productivity without compromising accuracy.

Programmable Testing Cycles:

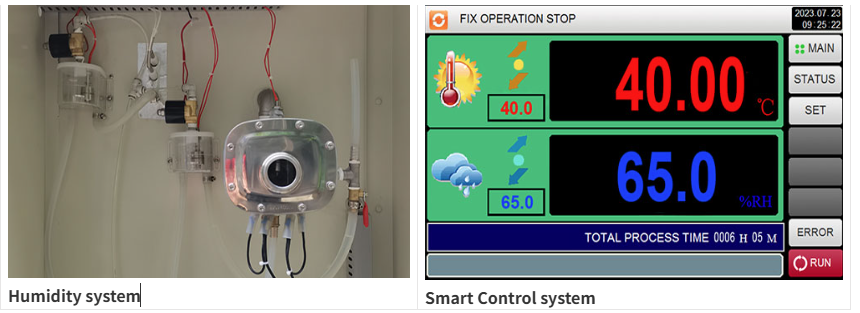

The intuitive control system enables pre-set or fully customized profiles, including gradual ramping, step cycles, or extreme condition simulations. Accelerated aging studies can be conducted to predict long-term stability in a fraction of the time.

Uniform Environmental Distribution:

Multi-directional air circulation eliminates “hot” or “cold” spots, ensuring that all samples experience identical conditions. This consistency is critical for accurate shelf life prediction.

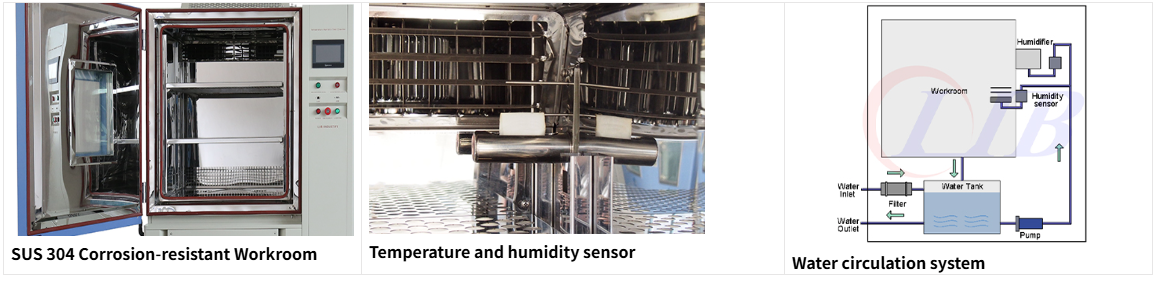

High-Accuracy Sensors & Real-Time Monitoring:

Multiple sensors provide continuous feedback, automatically logging data for compliance and audit purposes. Historical data can be analyzed to refine formulations or validate packaging changes.

Durable & Safe Construction:

SUS304 stainless steel interiors resist corrosion, are easy to clean, and provide long-term durability. Double-layer insulation improves energy efficiency, while over-temperature and humidity alarms protect both samples and equipment.

User-Friendly Operation:

A touch-screen interface simplifies program setup and monitoring. Remote access allows lab managers to check test progress off-site, improving operational flexibility.

|  | ||||

| Name | Temperature Humidity Chamber | ||||

Temperature range | -20℃ ~+150 ℃ | ||||

Low type | A: -40℃ B:-70℃ C -86℃ | ||||

Humidity Range | 20%-98%RH | ||||

Temperature deviation | ± 2.0 ℃ | ||||

Heating rate | 3 ℃ / min | ||||

Cooling rate | 1 ℃ / min | ||||

Controller | Programmable color LCD touch screen controller, Multi-language interface, Ethernet , USB | ||||

Refrigerant | R404A, R23 | ||||

Exterior material | Steel Plate with protective coating | ||||

Interior material | SUS304 stainless steel | ||||

Standard configuration | 1 Cable hole (Φ 50) with plug; 2 shelves | ||||

Timing Function | 0.1~999.9 (S,M,H) settable | ||||

Combines precision engineering with practical usability

Supports multi-industry compliance, ensuring valid and recognized results

Proven reliability in real-world labs, reducing variability, optimizing formulations, and supporting regulatory submissions

Designed for long-term operational efficiency, minimizing downtime and maximizing return on investment

With these capabilities, LIB industry chambers seamlessly integrate into laboratory workflows, providing reliable, actionable data for shelf life analysis.

Temperature and Humidity Chambers are designed to meet international standards such as ISO 9001 / ISO 22000 (food safety), ICH Q1A (pharmaceutical stability), ASTM D4332 (food and packaging durability), and FDA/GMP guidelines. These standards specify controlled temperature and humidity conditions, monitoring requirements, and data recording practices, ensuring that shelf life testing is reliable, reproducible, and audit-ready.

Here’s how LIB industry chambers are used to implement these standards in practice:

Samples of food, cosmetics, or pharmaceuticals are placed on adjustable racks. Standards require that samples be arranged to ensure uniform exposure to temperature and humidity. Multiple products can be tested simultaneously without affecting consistency, supporting ISO and ICH recommendations for multi-sample studies.

Pre-defined or fully customized temperature and humidity cycles are selected to simulate real-world storage or accelerated conditions. This step aligns with ICH Q1A guidance on stability testing, which emphasizes controlled environmental conditions over extended periods.

Chambers execute cycles with high precision, maintaining temperature deviations within ±0.5°C and humidity deviations within ±2% RH, as required by ISO and ASTM standards. Automated control ensures consistency, reduces operator error, and complies with documentation requirements for regulatory audits.

Temperature, humidity, and sample status are continuously monitored and automatically logged. Exportable data supports FDA/GMP compliance and internal quality control, allowing manufacturers to generate audit-ready reports in line with standard requirements.

Using the collected data, manufacturers assess product stability, optimize formulations, and validate packaging. This aligns with ISO and ICH recommendations for predictive shelf life testing, helping reduce returns, recalls, and customer complaints while maintaining product quality and regulatory compliance.

Q1: Can multiple samples be tested simultaneously?

Yes. Adjustable racks allow multi-sample testing without affecting uniformity or accuracy.

Q2: Are the chambers compliant with international standards?

Absolutely. All LIB industry chambers meet ISO, FDA, ICH, and ASTM standards.

Q3: What is the temperature/humidity ramp rate?

Ramp rate is fully adjustable to support gradual or rapid environmental changes.

Q4: Can the chamber be customized for unique sample sizes or workflows?

Yes. Interior volume, racks, and control programs can be fully customized.

Q5: How does this chamber improve operational efficiency?

Automated cycles, multi-sample capacity, and real-time monitoring reduce labor, increase repeatability, and save time on long-term studies.

LIB industry provides full support and customization for every Temperature and Humidity Chamber:

Warranty & Service: 3-year warranty and lifetime technical support

Installation & Training: On-site setup and comprehensive user guidance

Custom Configurations: Interior racks, chamber volume, and control programs tailored to your testing needs

Ensure your products maintain peak quality throughout their shelf life. Contact LIB industry today inquiry@libtestchamber.com for a personalized consultation and discover how our Temperature and Humidity Chambers can revolutionize your shelf life testing process.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia.png)