In real-world applications of modified plastics, product failure is rarely caused by insufficient mechanical design. Instead, it is often the result of long-term environmental exposure that gradually degrades material performance.

For commonly used modified plastics such as PP, ABS, ASA, and PA, prolonged outdoor exposure to ultraviolet radiation, elevated temperature, and moisture can trigger irreversible changes, including:

Embrittlement and impact strength loss caused by polymer chain scission

Severe discoloration and yellowing due to stabilizer depletion

Progressive mechanical deterioration driven by photo-oxidation and thermal oxidation

These failures are difficult to detect during early-stage laboratory testing, yet they often emerge after products enter the market—leading to customer complaints, warranty claims, and even large-scale recalls.

This is why ASTM G154 is widely recognized as the gold standard for UV exposure testing of non-metallic materials. By using controlled fluorescent UV light sources, it enables laboratories to accelerate outdoor weathering processes under repeatable conditions.

|  |

To proactively identify these hidden risks during product development, more and more modified plastics manufacturers are adopting high-irradiance UV weathering chambers compliant with ASTM G154, transforming uncontrollable outdoor variables into reliable, comparable laboratory data.

In UV aging testing, having UV light is not enough. What truly matters is how closely the spectrum and intensity replicate real sunlight.

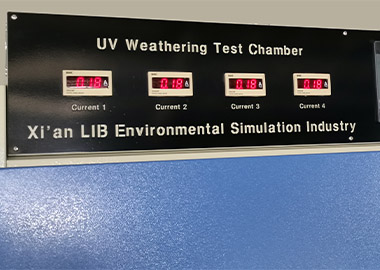

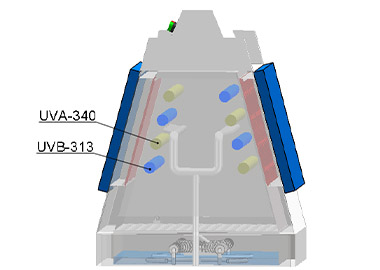

The UV weathering chamber is equipped with a mature and flexible fluorescent UV lamp system, allowing users to select the appropriate light source based on test objectives:

UVA-340 Lamps

Precisely simulate the critical short-wavelength portion of natural sunlight (295–365 nm), making them ideal for realistic outdoor exposure simulation and material performance comparison.

UVB-313 Lamps

Deliver higher energy output for rapid screening tests and extreme aging evaluations, significantly accelerating failure mechanisms.

To ensure both acceleration and accuracy, the system integrates a closed-loop irradiance control system (Solar Eye):

Irradiance control range: 0.35 – 1.55 W/m² @ 340 nm

Stability: ≤ ±0.02 W/m² throughout the test cycle

Real-time monitoring with automatic compensation for lamp aging

| |

|

|

Compared to conventional open-loop systems, this closed-loop control prevents irradiance drift caused by lamp degradation, ensuring repeatability and comparability across long-term and multi-batch tests.

At the same time, automatic compensation extends effective lamp life to over 1,600 hours, reducing operating costs without compromising data reliability.

Outdoor exposure is never driven by UV radiation alone.

The combined effects of light, temperature, and water ultimately determine the service life of modified plastics.

The chamber provides wide-range and high-accuracy black panel temperature control:

Temperature range: 30°C – 90°C

Control accuracy: ±0.3°C

Uniformity: ±2°C

Under elevated temperatures, UV radiation significantly accelerates thermal oxidation processes, making this feature critical for applications such as automotive exterior components and outdoor electrical housings.

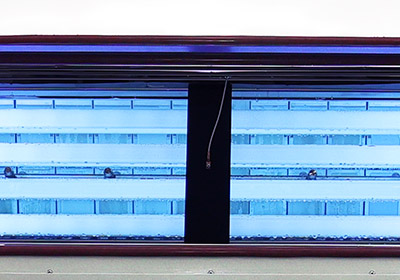

To realistically simulate dew formation, rainfall, and humid outdoor conditions, the system incorporates both condensation and spray functions:

Condensation Mode

Based on physical condensation principles, forming a 100% humidity moisture film on the specimen surface to accelerate additive migration and surface degradation.

Water Spray System

Adjustable spray pressure (7–10 psi) simulates rain impact, mechanical erosion, and thermal shock caused by alternating wet and dry conditions.

|  |

By coupling UV exposure with thermal and moisture stresses, test results more accurately reflect real-world aging behavior rather than simplified, single-factor UV exposure.

UV aging tests often require hundreds or even thousands of hours of continuous operation, making equipment durability just as important as test accuracy.

Inner chamber fabricated from SUS304 or SUS316 stainless steel

Excellent resistance to corrosion and oxidation

Designed to withstand prolonged exposure to heat, humidity, and condensation without structural degradation

This ensures a stable test environment and protects long-term data integrity.

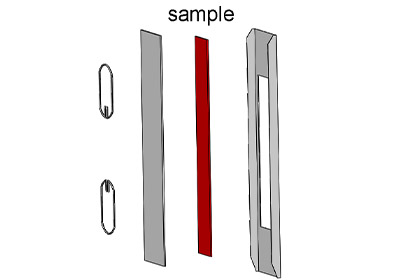

Standard specimen size: 75 × 150 mm

Maximum capacity: up to 48 flat specimens per test

Support for custom fixtures and irregular-shaped components

|  |

Higher specimen capacity directly translates into lower cost per test cycle and improved laboratory efficiency.

7-inch PLC color touchscreen interface

Pre-programmed ASTM G154 standard test cycles

Support for over 100 user-defined programs, accommodating different formulations and application requirements

|  |

The intuitive interface minimizes training time and reduces operator error.

| Standard | Description | Application |

|---|---|---|

| ASTM G154 | Fluorescent UV exposure practice for non-metallic materials | Plastics / Rubber |

| ISO 4892-3 | Plastics — Laboratory light sources — Fluorescent UV lamps | Modified engineering plastics |

| GB/T 16422.3 | Fluorescent UV lamp exposure method | Domestic compliance testing |

| SAE J2020 | Accelerated exposure of automotive exterior materials | Automotive interior & exterior parts |

A single investment supports multiple standards and product lines, maximizing long-term value.

For the modified plastics industry, a UV aging test chamber is more than just laboratory equipment—it is a preventive quality assurance tool that identifies risks early and aligns products with international standards.

By combining high irradiance output, precise control, and multi-stress environmental simulation, this system allows manufacturers to anticipate real-world performance in the laboratory, rather than reacting to failures in the field.

Contact us today inquiry@libtestchamber.com to receive a complimentary “Typical UV Aging Test Cycle Guide for Modified Plastics” along with the latest technical configuration and quotation.

3-year Warranty| Custom Configurations | Lifetime Support | ISO 17025 Calibration Available

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia