As electric vehicles, energy storage systems, and high-capacity lithium-ion batteries continue to scale globally, safety testing has become more critical than ever. Among all battery safety evaluations, thermal runaway testing stands out as the most demanding and high-risk procedure.

A single uncontrolled thermal event can lead to fire, explosion, toxic gas release, and catastrophic system failure. For manufacturers and certification laboratories, conducting thermal runaway experiments is no longer optional — it is mandatory for compliance and market access.

However, performing this test safely requires far more than a standard environmental chamber. It demands a purpose-built battery test chamber engineered specifically to withstand extreme conditions. LIB industry provides a comprehensive solution through its advanced Battery Thermal Runaway Test Chamber and complementary TH series chambers.

Thermal runaway occurs when internal chemical reactions generate heat faster than it can dissipate, triggering a self-accelerating chain reaction. Once initiated, temperatures can exceed 800°C within seconds.

International standards such as:

IEC 62133

UL 1642

UL 2580

SAE J2464

UN 38.3

require lithium-ion batteries to undergo abuse conditions including controlled heating, overcharge, short circuit, or mechanical damage to evaluate failure behavior.

For EV battery packs, energy storage modules, and research cells, demonstrating controlled thermal behavior is essential for certification, transportation approval, and insurance validation. This makes the Battery Thermal Runaway Test Chamber a cornerstone of modern battery development laboratories.

LIB industry also supports thermal runaway experiments for all EUCAR hazard levels (0–7), ensuring that the chamber accommodates a full spectrum of testing needs.

A true thermal runaway test environment must address three core challenges: extreme heat, explosive pressure, and hazardous gas management.

The chamber must provide:

Programmable heating rates (up to 5, 10, 15°C/min)

Wide temperature range (-70℃ to +150℃, up to +170℃ if required)

Temperature stability within ±0.5℃

Rapid thermal cycling capability

Precision is critical. Inconsistent heating may invalidate test results or fail to trigger representative failure modes. LIB industry battery test chambers use nickel-chromium alloy electric heaters combined with intelligent control to ensure uniform temperature distribution.

During thermal runaway, batteries may:

Burst violently

Release high-pressure gases

Produce flame jets

Fragment internally

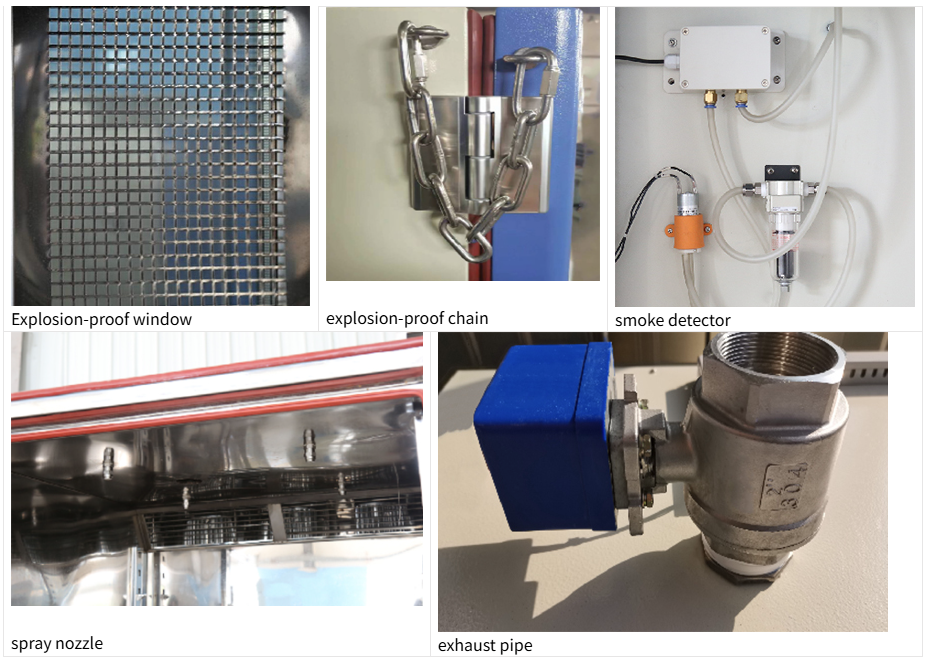

A conventional chamber is not designed for these mechanical stresses. LIB industry chambers employ a three-level explosion-proof design:

Chamber reinforced with 6mm SUS304 stainless steel

Pressure relief channel

Observation window with explosion-proof mesh

Explosion-proof lock and hinge chain

This ensures containment during high-energy failure events, while allowing visual monitoring. Movable shelving and customizable chamber volume support cylindrical, prismatic, and soft pack batteries of various sizes.

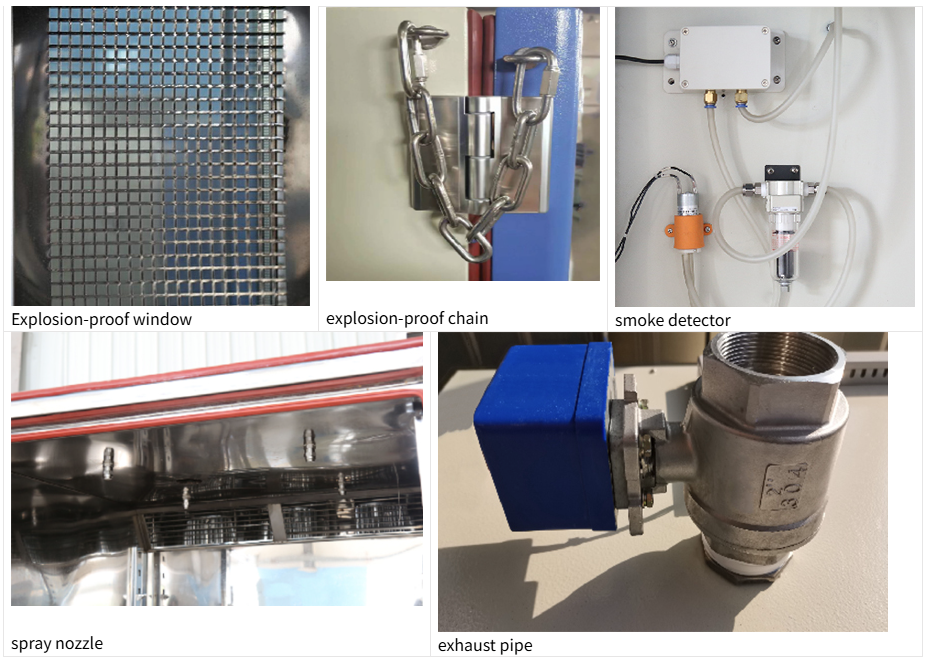

Thermal runaway often results in open flame and sustained combustion. LIB battery test chambers integrate:

Spray system to cool and prevent fire propagation

Automatic fire suppression

Emergency stop and remote shutdown

Smoke detection (alarm threshold >300PPM)

Pressure probe monitoring (>200KPa)

This combination allows real-time response to fire or smoke events while maintaining personnel safety.

Lithium-ion battery failure can release:

Carbon monoxide (CO)

Hydrogen (H₂)

Hydrogen fluoride (HF)

Flammable electrolyte vapors

Without proper exhaust systems, laboratory personnel and equipment are at serious risk. LIB battery test chambers provide:

High-efficiency smoke exhaust system

Forced ventilation for toxic gas removal

Optional gas analysis interface

Compliance with international laboratory safety standards

This ensures laboratory safety while maintaining reliable experimental results.

Some laboratories attempt to conduct thermal abuse tests in modified environmental chambers. This approach introduces significant risks:

Structural deformation or rupture during explosion

Fire spreading outside the chamber

Toxic gas leakage

Incomplete data acquisition

Non-compliance with certification standards

Beyond equipment damage, inadequate testing infrastructure can compromise personnel safety and invalidate regulatory approval. A properly engineered Battery Thermal Runaway Test Chamber eliminates these risks by integrating thermal control, explosion resistance, fire protection, and exhaust management into one system.

LIB industry specializes in high-performance battery test chamber systems engineered specifically for lithium-ion safety testing. Rather than modifying general-purpose equipment, LIB industry develops integrated safety solutions for high-risk battery abuse experiments.

Battery safety regulations continue to tighten worldwide. LIB industry designs its Battery Thermal Runaway Test Chamber systems to support testing aligned with:

IEC 62133

UL 1642

UL 2580

SAE J2464

UN 38.3

By ensuring structural integrity, data reliability, and environmental safety, LIB industry helps laboratories accelerate certification approval with confidence.

Model | TR10-1000C | |

Internal Dimension (mm)

| 1000*1000*1000 | |

Overall Dimension (mm)

| 2120*1200*2100 | |

Interior Volume | 1000L(Customizable) | |

Parameters | Temperature Range | C : -70℃ ~ +170 ℃(Customizable) |

Temperature Fluctuation | ± 0.5 ℃ | |

Temperature Deviation | ± 2.0 ℃ | |

Cooling Rate | 10 ℃ / min (average)(Customizable) | |

Heating Rate | 10 ℃ / min (average)(Customizable) | |

| ||

LIB industry chambers are built with:

Heavy-duty reinforced steel enclosure

Double-layer thermal insulation

Pressure relief ports

Explosion-proof observation window

This robust mechanical structure ensures reliable containment during high-energy failure events.

Accurate thermal stimulation is fundamental to reliable testing. LIB industry systems provide:

Multi-segment programmable temperature profiles

Adjustable ramp rates

High-precision PID control

Remote monitoring and cloud storage of test data

Automatic generation of test curves

These features allow engineers to simulate standardized abuse scenarios or design customized experimental profiles.

LIB industry integrates comprehensive safety protection including:

Automatic fire suppression

Spray system to prevent fire propagation

Emergency stop system

Over-temperature protection

Safety interlock design

Even during extreme battery ignition events, the system maintains operational safety and containment.

Uniform temperature and humidity are essential for reproducible test results. LIB battery test chambers feature:

High-efficiency air circulation fans

Humidity system using water evaporation to achieve ±2% RH accuracy

Integrated feedback control via PLC controller

This ensures environmental parameters remain stable even during rapid thermal cycling.

For extended battery testing requirements, LIB offers:

TH Series Chambers: Combine temperature and humidity with mechanical stress simulation

Thermal Shock/Impact Test Chambers: Evaluate structural resilience under vibration, drop, or collision

Rapid Thermal Change Chambers: Assess battery performance under fast heating/cooling transitions

These chambers can complement the Battery Thermal Runaway Test Chamber, supporting comprehensive battery validation workflows and safety certification.

LIB industry battery test chamber systems are widely used for:

EV battery pack development

Energy storage module validation

Power battery research institutes

Third-party certification laboratories

Aerospace battery testing

From single cells to full modules, customizable chamber dimensions and performance specifications are available to meet diverse testing demands.

Thermal runaway experiments are among the most dangerous procedures in battery validation — but they are also among the most important.

Choosing the right battery test chamber is not simply an equipment decision. It is a safety decision. It is a compliance decision. It is a long-term reliability decision.

LIB industry delivers:

Engineered explosion-proof design

Precision thermal control

Integrated fire suppression and spray system

Air circulation and humidity management

TH series, shock, and rapid-change chamber compatibility

Customizable configurations

3-year warranty and lifetime technical support

If you are planning to conduct thermal runaway experiments or upgrade your battery safety laboratory, LIB industry provides a complete, professional, and secure solution.

Contact LIB industry today to design your high-performance Battery Thermal Runaway Test Chamber system.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia