Imagine a car’s electronic control unit (ECU) on a frigid January morning in northern Canada. At dawn, it faces −40 °C. Hours later, after the engine runs, internal temperatures may spike above +80 °C. Engineers can’t wait years to see if the ECU survives—this is where thermal shock chambers come in, simulating rapid, extreme temperature changes to reveal vulnerabilities before products reach the field.

Aspect | Dual-Zone (2TS Series) | Three-Zone (3TS Series) |

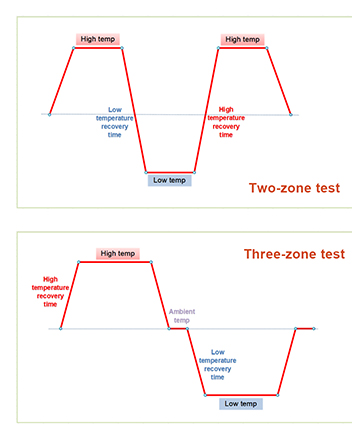

Chamber Layout | Two independent chambers (Hot & Cold) stacked vertically | Three chambers (Hot, Ambient, Cold) with fixed sample zone |

Sample Transfer | Movable basket shuttles samples between zones in ≤3 s | Airflow switching redirects hot/cold air to stationary samples in ≤15 s |

Transition Style | Creates abrupt, extreme temperature changes | Provides intermediate ambient stage for gradual transitions |

Mechanical Stress | Basket movement may add slight mechanical stress to samples | No movement—ideal for fragile or precision assemblies |

Space Efficiency | Compact, space-saving for smaller labs | Larger footprint but supports delicate testing |

|  |

Feature | Dual-Zone (2TS Series) | Three-Zone (3TS Series) |

Structure | Hot & Cold zones with a movable test basket (transfer ≤ 3 s) | Hot, Ambient, Cold zones with stationary samples, air switching |

Volume & Load | 22 L–505 L, 20–60 kg | 100 L–500 L+, 10–35 kg |

Temp Range | Hot: up to +220 °C, Cold: −75 °C | Hot: up to +220 °C, Cold: −75 °C |

Accuracy | ±0.5 °C | |

Control & Safety | PLC touchscreen, Ethernet, over-temp/over-current/leak protection | Same, plus multi-step programs and remote monitoring |

Recommended Applications | High-frequency rapid testing: PCBs, semiconductors, sensors, ECU modules | Large or sensitive assemblies: aerospace avionics, military devices, precision instruments |

Customization | Volume, temperature range, liquid-to-liquid or air-to-liquid transfers | Volume, weight, safety features, special processes |

Interpretation:

Dual-zone chambers excel at rapid cycling for small components, revealing micro-cracks or solder fatigue.

Three-zone thermal shock chambers provide controlled, gradual transitions, ideal for sensitive or large assemblies where sample stability is critical.

LIB chambers follow recognized international standards:

- IEC 60068-2-14 – Temperature Change Testing

- MIL-STD-883 – Microelectronics Thermal Shock

- JIS C0025 – Japanese electronics testing

These certifications ensure test results are globally accepted for product qualification.

· Automotive: Dual-zone chambers validate EV battery packs, sensors, and ECUs under rapid winter-to-summer simulations, often exposing solder joint fractures after fewer cycles.

· Aerospace: Three-zone chambers stress avionics boards for DO-160 compliance, revealing gradual delamination and thermal fatigue under long-term operation.

· Electronics: Semiconductor wafers and PCBs endure hundreds to thousands of cycles in both chamber types, producing different insights into early failure vs. long-term degradation.

· Defense & Precision Instruments: Stationary three-zone testing minimizes mechanical shock, helping ensure optical alignment and precision calibration remain intact even after harsh temperature cycling.

By replicating realistic conditions, engineers can detect weaknesses, refine designs, and reduce costly field failures.

· Rapid yet precise transfers (≤3 s in dual-zone, ≤15 s in three-zone)

· Fast temperature recovery (≤5 min)

· Customizable chamber sizes for both small and large samples

· Advanced PLC touchscreen with multi-program support and remote monitoring

· Safety & efficiency: over-temp protection, optional nitrogen purge, energy-efficient refrigeration

These features make LIB chambers reliable, safe, and adaptable to various industries.

Thermal shock testing bridges the gap between lab simulations and real-world performance. With both dual-zone and three-zone LIB chambers, engineers can select the right tool for their goals—whether they need fast screening of weak points or long-term reliability insights.

Ready to elevate your product testing? Explore LIB’s full range of Thermal Shock Chambers or contact our experts at inquiry@libtestchamber.com to design a custom solution tailored to your needs.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia