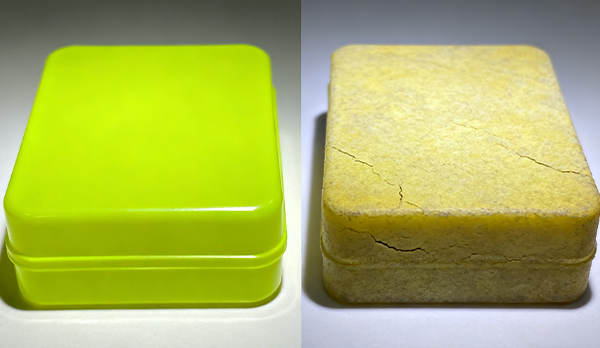

Plastics and coatings are essential materials in industries ranging from automotive and electronics to construction and consumer goods. However, exposure to UV radiation, heat, and moisture can significantly accelerate material aging. Common signs of degradation include color fading, surface cracking, chalking, gloss loss, and coating delamination.

Accelerated UV testing enables manufacturers to predict long-term material performance within a fraction of the real-world time. The ASTM G154 standard provides guidelines for testing UV effects on plastics and coatings, ensuring that products meet quality and durability expectations.

Key Statistics:

UV-induced discoloration occurs up to 10× faster in accelerated conditions.

Coating adhesion may reduce by 15–25% after 500 hours of UV exposure.

Lack of standardized testing can result in premature material failures, leading to higher warranty costs and brand reputation damage.

The UV Accelerated Aging Chamber replicates sunlight, heat, and moisture under controlled conditions. It is critical for evaluating plastics, coatings, rubbers, and composite materials, offering accurate predictions of product longevity.

Key Features and Specifications:

Feature | Specification | Benefit | |||

UV Lamp Type | UVA-340 / UVB-313 | Simulates natural sunlight spectrum | |||

Lamp Power | 0.3~20 W/㎡ | Adjustable intensity for various material sensitivities | |||

Temperature Range | Ambient ~ 90 ℃ ±2℃ | Tests materials under different thermal stresses | |||

Humidity Range | ≥95% RH | Simulates condensation and environmental moisture | |||

Specimen Capacity | 56 Pieces | Flexible testing for small to large samples | |||

Control System | Digital PID with programmable cycles | Ensures precision and repeatability | |||

Data Logging | Continuous monitoring & exportable reports | Facilitates compliance and analysis | |||

|

|

|

|

This UV accelerating aging chamber allows labs to conduct reliable and repeatable ASTM G154 tests, enabling data-driven material selection and product optimization.

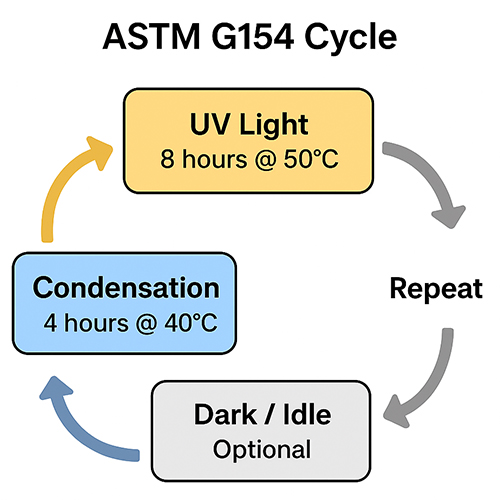

The ASTM G154 standard defines UV exposure testing cycles for plastics and coatings. Key aspects include:

UV Lamp Types: UVA-340 or UVB-313 to replicate sunlight spectrum

Exposure Cycles: 8 hours of UV light at 50°C

Condensation Cycles: 4 hours at 40°C to simulate dew formation

Total Test Duration: 500–2000 hours depending on material type

Predicts material lifespan accurately

Enables comparative analysis across different materials or suppliers

Ensures repeatable and reliable results

By adhering to ASTM G154, manufacturers can detect potential failure modes early and adjust material formulations or coatings accordingly.

Modern UV Accelerated Aging Chambers are engineered to meet ASTM G154 while offering enhanced flexibility:

UV Intensity Control: Lamp output is adjustable ±2% for consistent radiation.

Temperature & Humidity Stability: ±1°C and ±2% RH, critical for repeatable results.

Programmable Test Cycles: Fully customizable UV exposure, condensation, and dark cycles.

Automated Data Logging: Continuous monitoring of UV, temperature, and humidity for accurate reporting.

Flexible Workroom Sizes: Accommodates multiple sample sizes and types, from small lab specimens to larger panels.

These features ensure laboratory results accurately reflect real-world performance, giving engineers confidence in product durability.

The UV test chamber’s benefits extend beyond the lab:

Accelerates R&D Cycles: Quickly screen plastic compounds and coating formulations.

Predicts Product Lifespan: Provides early insights into color stability, cracking, and adhesion.

Optimizes Material Selection: Helps choose the most UV-resistant plastics and coatings for outdoor or industrial applications.

Reduces Costs: Minimizes warranty claims, returns, and material waste.

Supports Compliance: Aligns with international standards and industry regulations.

By combining UV Aging Chamber testing with ASTM G154 compliance, manufacturers make data-driven decisions that improve quality and customer satisfaction.

Q1: What types of materials can be tested?

A1: Plastics, coatings, rubbers, and composite materials; widely used in automotive, electronics, and consumer products.

Q2: How long does a typical ASTM G154 cycle last?

A2: Standard cycles range from 500 to 2000 hours depending on material type, UV intensity, and research objectives.

Q3: Can test parameters be customized?

A3: Yes. Lamp output, temperature, and humidity cycles are fully programmable to match ASTM G154 or custom protocols.

Q4: How is lifespan prediction possible?

A4: Accelerated testing results are correlated with real-world exposure, allowing engineers to forecast durability, color retention, and adhesion loss.

Q5: Is UV accelerating aging chamber maintenance expensive?

A5: Routine lamp replacement and filter cleaning are minimal in cost. Overall efficiency remains high with low downtime.

Combining UV Accelerated Aging Chamber testing with ASTM G154 compliance provides a scientifically validated, reliable method to evaluate plastic and coating durability. Benefits include:

Accurate lifespan and performance prediction

Early detection of material weaknesses

Optimized formulation and coating processes

Cost savings and reduced warranty claims

Take Action: Contact LIB industry inquiry@libtestchamber.com to explore professional UV Accelerated Aging Chambers, you will enjoy :

3-year warranty covering all major components

Lifetime technical support to solve any operational issues

Rapid response: 1–3 hours for urgent inquiries

Fast delivery: standard lead time of 7–15 working days.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia

_20251204110329.webp)