Cyclic corrosion test, also known as salt spray test or salt fog test, is an accelerated corrosion test designed to evaluate the corrosion resistance of materials, coatings, or products under harsh environmental conditions. It is widely used in industries such as automotive, aerospace, marine, and coatings to assess the performance and durability of materials and coatings under corrosive conditions.

In cyclic corrosion testing, test samples are exposed to alternating cycles of corrosive environments, including salt spray (or salt fog), humidity, and often temperature variations. Test samples typically undergo a series of different corrosion conditions, such as salt spray exposure followed by humidity exposure, followed by dry cycles, to simulate real-world environmental conditions that may lead to corrosion.

Salt spray exposure involves spraying a saltwater solution onto the test samples under controlled temperature and humidity, typically with a concentration of around 5% sodium chloride (NaCl). Salt spray creates a corrosive environment that accelerates the corrosion process and simulates the effects of exposure to saltwater or other corrosive atmospheres. Exposure to high humidity conditions, typically around 100% relative humidity, creates a moist environment that accelerates the corrosion process and promotes the formation of corrosion products. Temperature variation is often incorporated into cyclic corrosion testing to simulate the effects of thermal cycling and temperature changes that may occur in real-world environments. This may involve exposing the test samples to temperature variations from low to high to evaluate the effects of thermal stress on the corrosion resistance of materials and coatings.

Compared to natural exposure to corrosive environments over time, the cyclical nature of the testing, alternating exposure to salt spray, humidity, and temperature changes, is intended to accelerate the corrosion process and provide a more rigorous and expedited assessment of the corrosion resistance of materials or coatings.

Cyclic corrosion testing is typically conducted according to recognized standards such as ASTM B117 (Salt Spray Test), ISO 9227 (Salt Spray and Alternating Test), or other industry-specific standards to ensure consistency and standardization of the testing procedures and results. The results of cyclic corrosion testing are typically evaluated by measuring and recording the appearance and extent of corrosion on the test samples, such as the formation of rust, blisters, or other corrosion-related defects. These results can provide valuable information about the corrosion resistance and durability of materials or coatings and can be used for quality control, product development, material selection, and performance prediction across various industries.

1、Sample Preparation: Prepare samples according to the specifications outlined in relevant standards or testing requirements. This may involve preparing samples of specific dimensions, cleaning and treating samples to remove contaminants or surface coatings, and applying any required surface treatments or coatings.

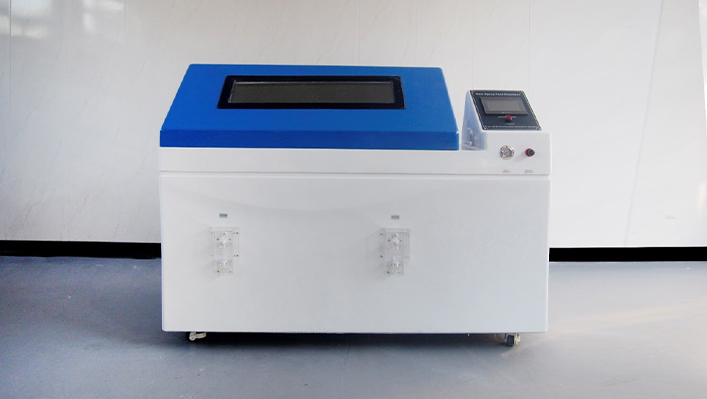

2、Setup Testing Chamber: The cyclic corrosion testing chamber is prepared according to the testing standards or requirements. This may involve adjusting the chamber's temperature, humidity, and salt fog concentration to the desired levels as per the testing specifications.

3、Placement of Samples in the Test Chamber: Prepared samples are carefully placed within the test chamber, ensuring they are positioned correctly and securely to be uniformly exposed to the corrosive environment. Depending on the testing standards or requirements, samples may be suspended or mounted in specific orientations or configurations.

4、Initiate Cyclic Corrosion Test: Start the test chamber and initiate the cyclic corrosion test by exposing the test samples to predetermined cycles of salt fog, humidity, and temperature variations as per the testing standards or requirements. Test samples are typically exposed to these cyclic conditions for a specific duration, ranging from hours to weeks or even months, depending on the testing requirements and standards.

5、Monitor and Record Test Conditions: Test conditions, including temperature, humidity, salt fog concentration, and any other relevant parameters, are closely monitored throughout the testing period and recorded at specified intervals as per the testing standards or requirements. This helps ensure that test conditions are maintained within the desired range and provides accurate data for subsequent analysis.

6、Inspect and Evaluate Test Samples: At the conclusion of the specified testing duration, carefully remove the test samples from the test chamber and inspect and evaluate their appearance and condition according to the testing standards or requirements. This may involve visual inspections, measurements of corrosion-related defects, and documentation of the results.

7、Analysis and Interpretation of Results: Analyze and interpret the results of the cyclic corrosion test, including the appearance and extent of corrosion on the test samples, according to the testing standards or requirements. This may involve comparing the results to established standards, rating criteria, or performance requirements to determine the corrosion resistance and durability of the tested materials or coatings.

8、Draw Conclusions and Take Appropriate Action: Draw conclusions regarding the corrosion resistance and durability of the tested samples based on the results of the cyclic corrosion test. If the materials or coatings meet the required performance standards, further action may not be necessary. If the materials or coatings fail to meet the performance requirements, further action may be needed, such as adjusting material formulations, modifying coating processes, or retesting under different conditions.

9、Reporting and Documentation: Record the results of the cyclic corrosion test, including test conditions, observations, and conclusions, in a comprehensive test report according to the testing standards or requirements. This report serves as a record of the testing process, results, and conclusions and can be used for quality control, product development, and other purposes.

Additionally, the specific testing steps for cyclic corrosion testing may vary depending on the testing standards, industry, and specific requirements of the test.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia