Walk-In Corrosion Test Chamber Features and Benefits

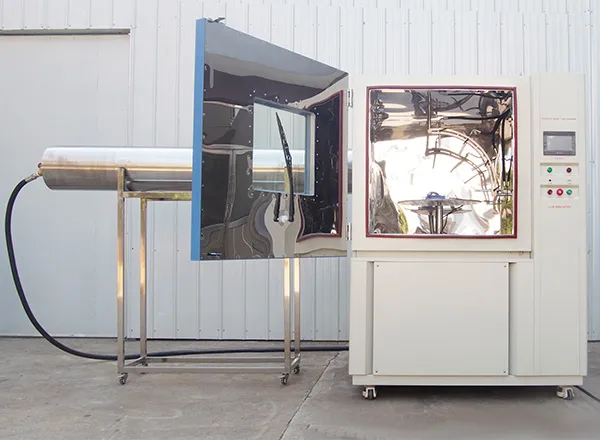

1. The test space can be customized: ranging from a few cubic meters to several tens of cubic meters, supporting non-standard customization, and suitable for various large-sized products.

2. The salt spray is evenly distributed: using a corrosion-resistant spray tower system (the number depends on the size of the laboratory) and reasonable air flow organization to ensure consistency of the test environment.

3. Corrosion-resistant structural design: Inner is 316L stainless steel, Outer is steel plate with protective coating, adapted to long-term salt spray corrosion environment.

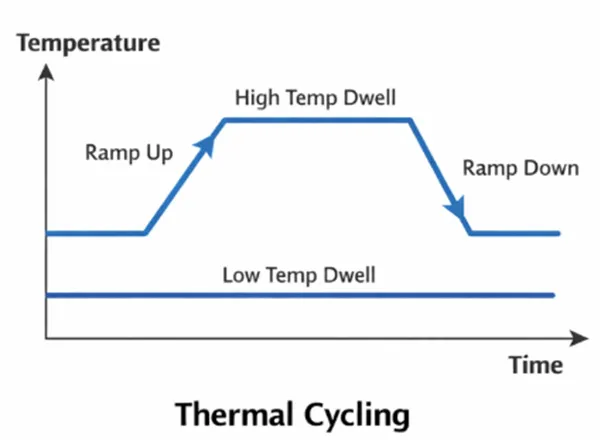

4. Suitable for multiple standards: can be used for ordinary salt spray testing and cyclic salt spray testing, and can also be used for the double 85 test of photovoltaic panels.

Walk-In Corrosion Test Chamber Specifications

Name | Walk In Corrosion Test Chamber |

Temperature Range | +10 ℃ ~ +90 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 30% ~ 98% RH |

Humidity Deviation | + 2%, - 3% |

Salt Fog Deposition | 1~2ml / 80cm2 · h |

Cooling system | Mechanical compression refrigeration system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Water supply system | Water purification system |

Spraying System | Atomizer tower and Spray nozzles |

Salt Fog Collected | Fog collector and fog measure cylinder |

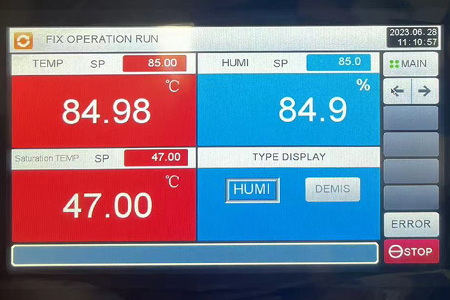

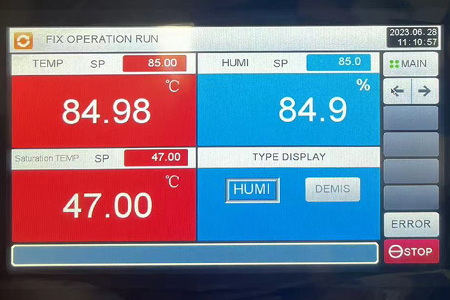

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Air Circulation | Centrifugal wind fan |

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection |

Details of Walk-In Corrosion Test Chamber

Workroom | At the top of the inverted V groove, it prevents salt fog from condensing and dripping onto the test piece. Made of SUS316 material, it can resist high temperatures, high humidity, and high salt fog corrosion. Customized sample holders for placing or hanging the test pieces.

|

|

| Salt Spray Tower | The spray system is equipped with dedicated pneumatic atomizing nozzles, and the nozzles are evenly distributed, with the deposition volume controlled within 1.0 - 2.0 ml/80cm²·h. Quartz nozzles are easy to clean and resistant to high temperatures, corrosion, and clogging.

|  |

Salt Solution Tank | The salt water is guided through corrosion-resistant pipelines to the spray tower, ensuring a stable liquid flow rate and a constant spray pressure. An internal salt water mixing system maintains the pH value of the salt solution.

|  |

| Touchscreen Controller | PLC touchable controller, multi-language interface, data recording, USB export and remote monitoring functions. Programmable to run multiple test programs, automatically control spray time, stop spray time, temperature and humidity parameters, and achieve standardized, unmanned, long-term testing.

|  |

LIB industry specializes in the manufacturing of environmental test chambers and offers high-performance and highly reliable walk-in salt spray test chamber solutions. Whether you need standard models or customized non-standard ones, we can design and deliver them on demand.

All equipment comes with a 3-year warranty and lifetime technical support. In addition, LIB industry provides comprehensive after-sales services including remote diagnosis, software upgrades, regular calibrations, and on-site training.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia