In an era where electronic components are rapidly miniaturizing, environmental testing must evolve to meet the scale and sensitivity of the devices being developed. While traditional temperature humidity chambers are powerful tools, they are often oversized and inefficient when dealing with small samples like IC chips, MEMS sensors, or micro PCBs.

This is where LIB’s Mini Temperature Humidity Chambers stand out—not just in size, but in purpose-built performance.

Micro-components have precise tolerances and require equally precise testing environments. A full-sized chamber not only wastes energy and lab space but also risks inaccurate results due to oversized airflow dynamics and slow ramping when testing very small masses.

LIB’s mini chambers are engineered specifically for:

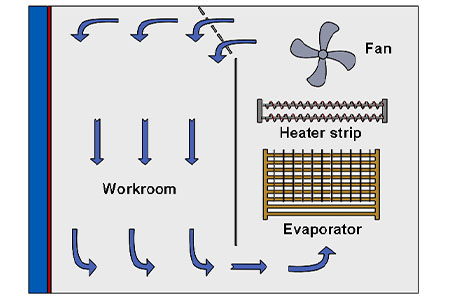

- Targeted airflow control optimized for small test zones

- Faster thermal response for minimal samples

- Space-efficient design for desktop or benchtop integration

- Fine humidity control without over-saturation or pooling on small surfaces

This makes them the ideal tool for R&D and QA labs working with critical microelectronics.

Test Component | MEMS pressure sensor (used in automotive and industrial control) |  |

Test Objective | To verify long-term reliability under fluctuating humidity and thermal stress | |

Standard Referenced | JEDEC JESD22-A104D (Temperature Cycling) + JESD22-A101C (Steady-State Humidity Life Test) |

Test Procedure using LIB Mini Temperature Humidity Chamber:

1. Mounting:

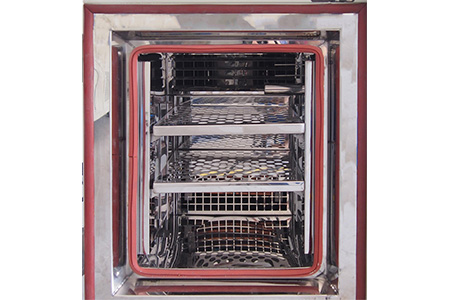

Sensors are securely placed on a custom tray inside a 50L LIB mini chamber with uniform airflow.

2. Temperature Cycling:

- From -40°C to +125°C

- Dwell time: 10 min at extremes

- Total cycles: 1000

3. Humidity Exposure (85/85 Test):

- 85°C, 85% RH for 1000 hours

- Per JESD22-A101C

4. Post-test Evaluation:

Sensor drift and packaging integrity are measured.

The small chamber ensures tight thermal uniformity and stable RH control even with minimal test mass. The fast ramp rate minimizes non-productive time, while compact dimensions reduce energy consumption by over 30% compared to standard chambers.

Feature | Uniqueness for Micro Testing | |

Micro Airflow System | Prevents over-drying or condensation on delicate samples |  |

Stable RH Control ±2.5% | Essential for high-impedance electronics like sensors and ICs | |

Quick Ramp Rate | Faster temperature transitions reduce test duration |  |

Modular Sample Holders | Easily configurable for different shapes/sizes of micro parts |  |

USB + Ethernet Data Export | Useful for logging long-duration reliability test data |  |

- IC packaging moisture sensitivity per IPC/JEDEC J-STD-020

- Flexible sensor testing under cyclic high humidity

- Small PCB thermal shock reliability

- Medical microdevice qualification with strict thermal tolerances

- Wearable electronics testing with limited batch samples

As technology moves toward smaller and more complex components, LIB’s mini temperature humidity chambers provide a high-precision, high-efficiency testing platform tailored to microelectronics. With compliance to JEDEC, IPC, and automotive-grade standards, they are a trusted partner in ensuring your miniature components perform reliably—regardless of the environment.

If you're testing components that fit in the palm of your hand, you need a chamber that fits the challenge just as precisely.Contact LIB at inquiry@libtestchamber.com to get more specs.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia