Ozone is one of the most aggressive environmental factors contributing to the aging of rubber, plastics, and elastomeric materials. Even at low concentrations, ozone (O₃) can lead to surface cracking, loss of flexibility, and eventual failure of products exposed to the outdoors or industrial environments. To evaluate the durability of these materials, ozone test chambers are used in laboratories to replicate ozone exposure under controlled conditions.

Two primary testing methods are used in ozone test chambers: static ozone testing and dynamic ozone testing. Understanding the difference between them is essential for selecting the appropriate method and equipment.

In static testing, samples are exposed to ozone gas while remaining stationary and unstressed. This type of test is designed to simulate passive ozone exposure—such as the conditions experienced by stationary rubber seals, gaskets, and insulation materials over time.

✔ Ideal For:

- Long-term weathering simulation

- Products not under mechanical load

- Surface-level cracking evaluation

In dynamic testing, samples are placed under continuous mechanical stress—typically stretched, flexed, or rotated—during ozone exposure. This method better simulates real-world conditions where rubber materials are in motion or tension, such as automotive tires, belts, or bushings.

✔ Ideal For:

- Operational stress simulation

- Accelerated aging under mechanical tension

- Fatigue and deep crack formation analysis

Feature | Static Testing | Dynamic Testing |

Sample Movement | None | Required (e.g., tension, rotation, flexing) |

Mechanical Stress | No | Yes |

Test Purpose | Simulate storage/exposure aging | Simulate operational fatigue |

Cracking Behavior | Surface-level, initial cracks | Deep, stress-related cracking |

Common Applications | Seals, insulation, gaskets | Tires, belts, hoses, engine mounts |

Standard Test Methods | ASTM D1149, ISO 1431 | JIS K6259, ASTM D518 |

Ozone Concentration Range | 1 – 1000 pphm |

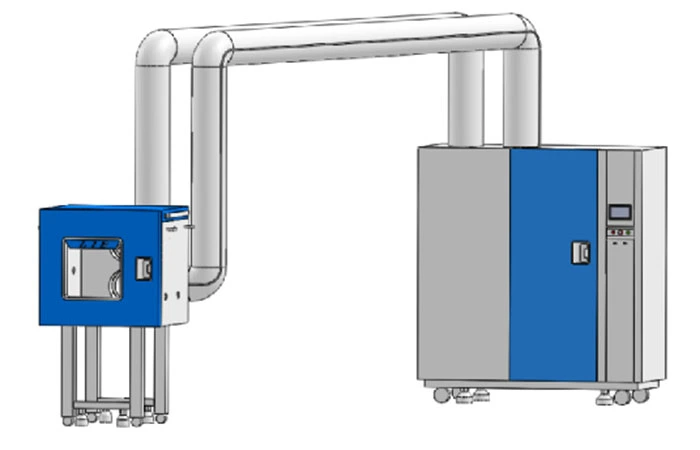

Test Room Volume | Standard: 250L – 1000L; Custom sizes available |

Chamber Material | SUS304 stainless steel interior, powder-coated steel exterior |

Temperature Range | Optional: Ambient to +100°C |

Air Circulation System | High-efficiency fan with uniform ozone distribution |

Dynamic Fixture Options | Rotating wheels, tensile fixtures, custom movement setups |

Controller Interface | Programmable touchscreen (USB & Ethernet interface) |

Compliance Standards | ASTM D1149, ISO 1431, JIS K6259, ASTM D518 |

With over two decades of experience, LIB Industry has established itself as a reliable partner for environmental simulation solutions. Our ozone aging testing machines are used by clients in automotive, aerospace, electronics, and rubber manufacturing industries worldwide.

We provide:

Customizable test chambers to suit unique product sizes or standards

Professional guidance and training for installation and usage

Global support with CE/UL certifications and long-term technical service

Flexible solutions for R&D, quality control, or third-party compliance labs

Whether your goal is to simulate outdoor exposure or predict material fatigue under stress, LIB’s ozone test chambers deliver reliable and repeatable performance.

Choosing between static and dynamic ozone testing depends on the material's end-use environment. Static testing is sufficient for products in storage or minimal motion, while dynamic testing provides deeper insights into operational durability.

Contact LIB inquiry@libtestchamber.com today to get a tailored ozone testing solution that matches your technical and regulatory needs.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia