For material weather resistance testing, the UV aging test chamber is the core equipment for simulating the aging behavior of materials under natural light conditions. By reproducing the ultraviolet (UV) spectrum, temperature, and humidity of real-world environments, manufacturers can quickly predict how coatings, plastics, or composites will perform after years of outdoor exposure.

|  |

Among various configurations, the UVA340 lamp and UVB313 lamp are two mainstream UV light sources used in UV aging test chambers. Due to their distinct spectral characteristics, they are suitable for different test objectives and application fields. Understanding their difference is essential to choosing the right UV lamp for accurate and reliable material testing.

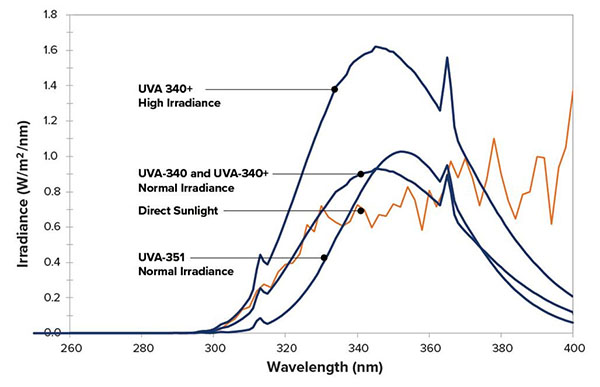

The emission spectrum of the UVA340 lamp is concentrated near 340 nm, which corresponds closely to the ultraviolet band of 295–365 nm in sunlight. It can accurately reproduce the ground-level ultraviolet energy filtered by the atmosphere. According to ASTM G154, the spectral distribution of UVA340 is more than 90% similar to the ultraviolet portion of midday summer sunlight, making it the preferred light source for outdoor material aging tests.

The UVA340 lamp provides a stable, long-wave UV exposure ideal for automotive coatings, architectural finishes, photovoltaic panels, and polymer films. These applications require realistic long-term simulation of sunlight to evaluate color change, gloss loss, and micro-cracking over hundreds or even thousands of test hours.

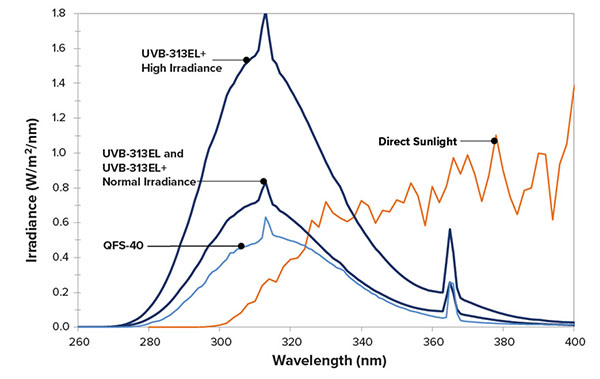

In contrast, the UVB313 lamp emits radiation concentrated in the short-wave UV region (280–320 nm), with peak intensity around 313 nm. Its energy output is about 40% higher than that of the UVA340, which significantly accelerates the photodegradation of materials. This high-energy short-wave exposure increases the testing speed, allowing for rapid screening of materials, additives, or formulations.

However, since UVB313 radiation is more intense than natural sunlight, it may cause degradation phenomena that are not typical of outdoor exposure—such as embrittlement, chalking, and molecular chain fracture. Therefore, it is mainly used for extreme condition evaluation, military material testing, or quick comparison of UV stabilizers.

Test Requirements | UVA340 Application | UVB313 Application |

Test Objectives | Real outdoor environment simulation | Rapid screening / extreme condition assessment |

Typical Industries | Automotive coatings, building facades, photovoltaic panels | Plastic additive verification, military materials testing |

Test Cycle | Medium to long cycle (hundreds to thousands of hours) | Short cycle (tens to hundreds of hours) |

Damage Type | Photooxidation, micro-cracking, color change | Embrittlement, pulverization, molecular chain fracture |

In practical use, UVA340 lamps are recommended when users aim to reproduce natural sunlight exposure as accurately as possible, while UVB313 lamps are preferred for accelerated life testing to identify weaknesses or validate material improvements quickly. Many advanced laboratories use a combined testing approach—starting with UVA340 exposure for realistic simulation and then applying UVB313 radiation to accelerate degradation analysis.

LIB industry integrates both UVA340 and UVB313 lamp options in its UV aging test chambers, offering unmatched flexibility for research, quality control, and reliability assessment. Whether your goal is to simulate outdoor weathering or conduct high-intensity accelerated aging, LIB industry’s systems ensure consistent irradiance and precise temperature–humidity coordination.

Internal Dimension (mm) | 450*1170*500 |

Overall Dimension (mm) | 610*1330*1470 |

Specimen Holder Size(mm) | 75*150 |

Specimen Capacity | 56 Pieces |

Irradiation Source | Fluorescent UV lamps (8) - 40 W |

Temperature Range | Ambient ~ 90 ℃ ±2℃ |

Black Panel Temperature (BPT) | 35 ~ 80 ℃ |

Humidity Range | ≥95% RH |

Bandwidth | 290 ~ 400nm |

Irradiance Control | 0.3~20 W/㎡ |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Distance of Specimen and lamp | 50mm |

| |

|

|

LIB’s UV aging test chambers support mixed UVA340 and UVB313 programming, enabling users to simulate ultraviolet intensity distributions of different latitudes and seasonal conditions. The fluctuation of UV irradiance within the test workroom is controlled within ±2%, which is five times more stable than the typical industry standard—ensuring reproducible, precise results even during long test cycles.

Through “Light–Heat–Humidity” collaborative control, LIB equipment integrates temperature (RT ~ 90 °C), humidity (≥95% RH), and water spray modules to replicate real environmental stress. The system supports ASTM G154, ISO 4892, and more than 12 international testing standards, providing comprehensive coverage for material weathering studies.

Each UV test chamber is equipped with a LIB industry PLC intelligent controller, supporting real-time data analysis, automatic report generation, and abnormal condition alerts. Remote monitoring capabilities allow operators to view the test process and make parameter adjustments without manual intervention, improving testing efficiency and traceability.

LIB UV aging test chambers are fully compliant with ASTM G154, ISO 4892-3, and GB/T 16422.3 standards, ensuring global compatibility and credibility in laboratory certification. They are widely applied in automotive coatings, building materials, photovoltaic modules, plastics, paints, packaging, and polymer R&D, offering reliable data for product durability evaluation and quality improvement.

Ready to Evaluate Your Materials with Confidence?

Leave a message inquiry@libtestchamber.com to receive your free copy of the “UV Aging Test Chamber White Paper.” within 1~3 hours. Discover how LIB industry’s UVA340 and UVB313 solutions can help you accelerate product development and ensure long-term reliability. All customers enjoy 3 years of extended maintenance, complimentary spectrum calibration training, and expert technical consultation from LIB industry’s professional engineering team.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia