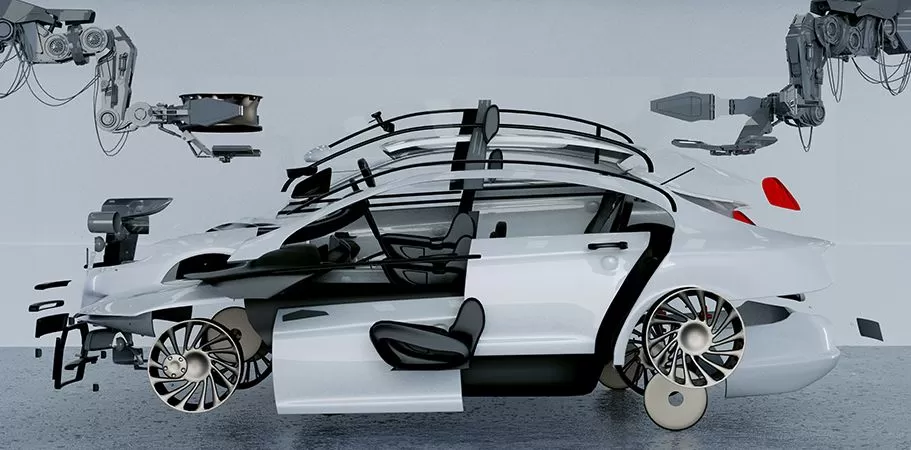

With the automotive industry constantly changing and adding new innovative technology, the need for testing either for research or manufacturing is more important than ever. Environmental test chambers aid in this testing for a variety of components. LIB INDUSTRY has extensive experience in producing environmental test chambers and uses the most advanced testing and equipment for these components and engines testing.

Corrosion testing is a more realistic salt spray test than traditional constant state exposure, because actual outdoor exposure usually includes both wet and dry environments, and we make laboratory accelerated testing meaningful by simulating these natural, periodic conditions. The salt spray test chamber is suitable for salt spray corrosion tests of parts, electronic components, protective layers of metal materials and industrial products.

Environmental Chamber For Corrosion Test | |

|

|

| |

LIB vibration chamber exposes products to natural or artificial environmental conditions, and test the performance of various parts of the automobile under actual use, transportation and storage environmental conditions, verifying that automotive components meet expected quality targets.

Environmental Chamber For Temperature Humidity Vibration Test | |

| |

High and low temperature thermal shock test is mainly suitable for the climatic and environmental change performance test of electronic components and auto parts of automotive, and provides environmental reliability test.

Environmental Chamber For Thermal Shock Test | |

Temperature And Humidity Chamber | |

To test the dust proof grade, water proof grade and service life of the products, by simulating natural sand and rain environment.

Environmental Chamber For IP Dust and Water Ingress Test | |

| |

| ip x3 X4 Test Chamber |

| |

To simulate the sunlight spectrum to reproduce destructive sunlight in different environments and provide corresponding environmental simulation and accelerated testing for scientific research, product development and quality control. LIB xenon arc chamber and uv test chamber are available for testing.

Environmental Chamber For Accelerate Weathering Test | |

| |

With over 16 years of experience in the automotive industry, LIB INDUSTRY provides excellent services to automotive system and test chambers for environmental testing in global markets.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia