Calibrating Temperature and Humidity Devices—A Practical Use Case for Benchtop Temperature and Humidity Test Chambers

In every lab or factory that depends on accurate environmental data, there's one quiet but critical task that keeps everything running right: sensor calibration. Temperature and humidity data logg...

Calibrating Temperature and Humidity Devices—A Practical Use Case for Benchtop Temperature and Humidity Test Chambers

In every lab or factory that depends on accurate environmental data, there's one quiet but critical task that keeps everything running right: sensor calibration. Temperature and humidity data logg...

Update of the LIB Salt Spray Corrosion Test Chamber

IntroductionFor laboratories and manufacturers that rely on salt spray testing for product quality assurance, equipment reliability and usability are key. To meet evolving customer needs and industry ...

Update of the LIB Salt Spray Corrosion Test Chamber

IntroductionFor laboratories and manufacturers that rely on salt spray testing for product quality assurance, equipment reliability and usability are key. To meet evolving customer needs and industry ...

Ozone Test Chamber for Rubber: Accelerated Aging Under Controlled Conditions

Rubber is a vital material in countless applications—from automotive seals and gaskets to electrical insulators, hoses, and tires. Its flexibility, durability, and resistance to weathering make it in...

Ozone Test Chamber for Rubber: Accelerated Aging Under Controlled Conditions

Rubber is a vital material in countless applications—from automotive seals and gaskets to electrical insulators, hoses, and tires. Its flexibility, durability, and resistance to weathering make it in...

Comparing LIB Multiple Temperature Chambers: Which Model Fits?

Choosing the right temperature chamber is essential for ensuring product reliability under extreme environmental conditions. LIB Industry offers a full range of temperature chambers designed to meet d...

Comparing LIB Multiple Temperature Chambers: Which Model Fits?

Choosing the right temperature chamber is essential for ensuring product reliability under extreme environmental conditions. LIB Industry offers a full range of temperature chambers designed to meet d...

Static VS. Dynamic Ozone Testing in Ozone Test Chambers

Understanding Ozone Aging Methods and Choosing the Right LIB EquipmentOzone is one of the most aggressive environmental factors contributing to the aging of rubber, plastics, and elastomeric materials...

Static VS. Dynamic Ozone Testing in Ozone Test Chambers

Understanding Ozone Aging Methods and Choosing the Right LIB EquipmentOzone is one of the most aggressive environmental factors contributing to the aging of rubber, plastics, and elastomeric materials...

Precision in Small Scale: The Unique Role of Mini Temperature Humidity Chambers in Microelectronics Testing

In an era where electronic components are rapidly miniaturizing, environmental testing must evolve to meet the scale and sensitivity of the devices being developed. While traditional temperature humid...

Precision in Small Scale: The Unique Role of Mini Temperature Humidity Chambers in Microelectronics Testing

In an era where electronic components are rapidly miniaturizing, environmental testing must evolve to meet the scale and sensitivity of the devices being developed. While traditional temperature humid...

JIS Z 2371 Salt Spray Test Chamber Guide – Avoid Common Testing Mistakes with LIB Leading Test Chamber Manufacturer Solutions

Why JIS Z 2371 Salt Spray Testing Is CriticalCorrosion is one of the most costly forms of material degradation, especially for products exposed to marine or industrial environments. JIS Z 2371 provide...

JIS Z 2371 Salt Spray Test Chamber Guide – Avoid Common Testing Mistakes with LIB Leading Test Chamber Manufacturer Solutions

Why JIS Z 2371 Salt Spray Testing Is CriticalCorrosion is one of the most costly forms of material degradation, especially for products exposed to marine or industrial environments. JIS Z 2371 provide...

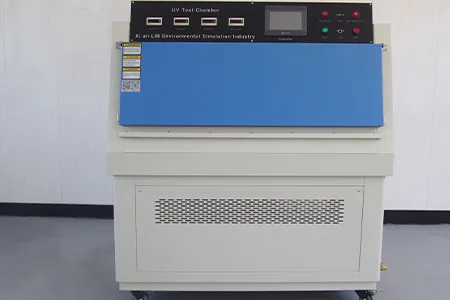

LIB UV Aging Machine Applications in Coatings and Paints – Preventing Fading and Cracking

Paints and coatings are designed not only for aesthetics but also to protect underlying materials against environmental stress. However, prolonged outdoor exposure to sunlight, rain, and humidity inev...

LIB UV Aging Machine Applications in Coatings and Paints – Preventing Fading and Cracking

Paints and coatings are designed not only for aesthetics but also to protect underlying materials against environmental stress. However, prolonged outdoor exposure to sunlight, rain, and humidity inev...

Optimizing Environmental Testing: A Guide to LIB Humidity and Temperature Control Chambers

IntroductionEnvironmental testing chambers (TH Series) provide critical simulation capabilities for research, development, and quality assurance across industries. These systems offer precise control ...

Optimizing Environmental Testing: A Guide to LIB Humidity and Temperature Control Chambers

IntroductionEnvironmental testing chambers (TH Series) provide critical simulation capabilities for research, development, and quality assurance across industries. These systems offer precise control ...

A Technical Overview of Xenon Arc Test Instruments: Capabilities & Design Considerations by LIB

Xenon arc test Instruments are pivotal in material science for evaluating the weatherability and lightfastness of products. By simulating the full spectrum of sunlight, along with controlled temperatu...

A Technical Overview of Xenon Arc Test Instruments: Capabilities & Design Considerations by LIB

Xenon arc test Instruments are pivotal in material science for evaluating the weatherability and lightfastness of products. By simulating the full spectrum of sunlight, along with controlled temperatu...

UV Light Accelerated Weathering Tester for SAE J2020 — Practical Setup with LIB UV‑SI‑260

Why SAE J2020 matters (and how it’s different)SAE J2020 defines how to run fluorescent UV + condensation exposures for automotive exterior materials. It focuses on the damage mechanisms that dominate...

UV Light Accelerated Weathering Tester for SAE J2020 — Practical Setup with LIB UV‑SI‑260

Why SAE J2020 matters (and how it’s different)SAE J2020 defines how to run fluorescent UV + condensation exposures for automotive exterior materials. It focuses on the damage mechanisms that dominate...

LIB Custom Multi-Environment Test Chamber for Jewellery – Meeting International Standards with Tailored Solutions

Jewellery testing is not just about checking shine and durability; it’s about ensuring products meet strict global standards to withstand real-world conditions. Sweat, sulphur gases, UV light, humidi...

LIB Custom Multi-Environment Test Chamber for Jewellery – Meeting International Standards with Tailored Solutions

Jewellery testing is not just about checking shine and durability; it’s about ensuring products meet strict global standards to withstand real-world conditions. Sweat, sulphur gases, UV light, humidi...

LIB Comprehensive Guide to Concrete Durability Testing: From Temperature Cycling to Salt Spray Corrosion

Concrete drying, shrinkage and long-term durability depend directly on the interaction of temperature, humidity and chemical exposure. For laboratory teams working on drying kinetics, curing protocols...

LIB Comprehensive Guide to Concrete Durability Testing: From Temperature Cycling to Salt Spray Corrosion

Concrete drying, shrinkage and long-term durability depend directly on the interaction of temperature, humidity and chemical exposure. For laboratory teams working on drying kinetics, curing protocols...

Temperature Cycle Test Equipment for Electronics and Automotive Reliability

IntroductionWhen an electronic control module inside a car suddenly fails on a scorching summer day or a freezing winter morning, the root cause often lies in one thing—thermal stress. Components exp...

Temperature Cycle Test Equipment for Electronics and Automotive Reliability

IntroductionWhen an electronic control module inside a car suddenly fails on a scorching summer day or a freezing winter morning, the root cause often lies in one thing—thermal stress. Components exp...

When 1000 Hours Equals 10 Years: Translating Cyclic Corrosion Test Results into Real-Life Durability

Introduction: The Misunderstood EquationIn industrial testing, one phrase is often repeated: “1000 hours of salt spray equals 10 years of outdoor durability.”It’s catchy, but dangerously misleading...

When 1000 Hours Equals 10 Years: Translating Cyclic Corrosion Test Results into Real-Life Durability

Introduction: The Misunderstood EquationIn industrial testing, one phrase is often repeated: “1000 hours of salt spray equals 10 years of outdoor durability.”It’s catchy, but dangerously misleading...