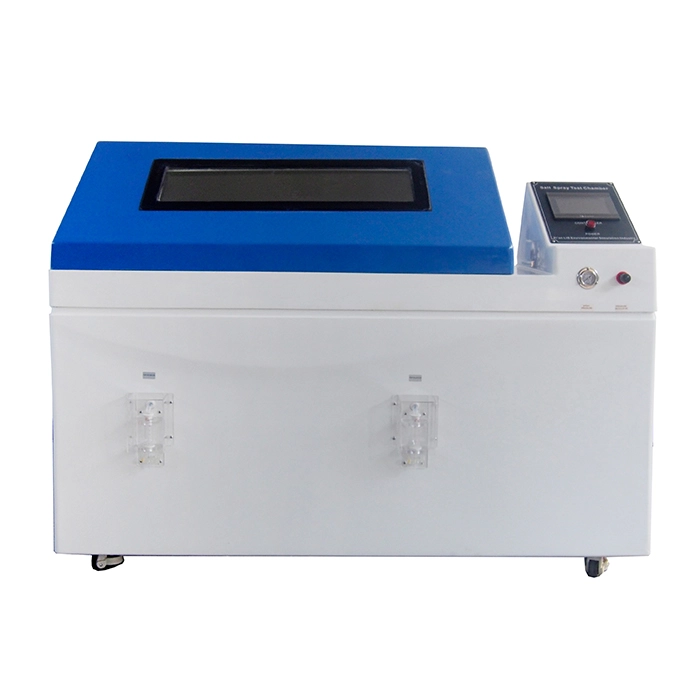

Temperature Chamber Features and Benefits

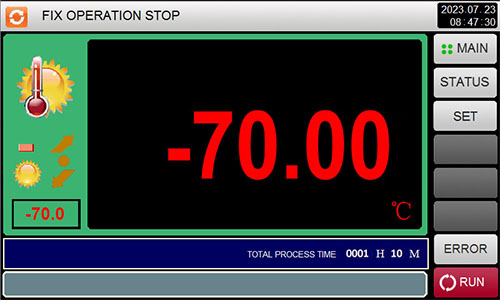

1. Wide Temperature Range & Configurable Low-Temperature Options

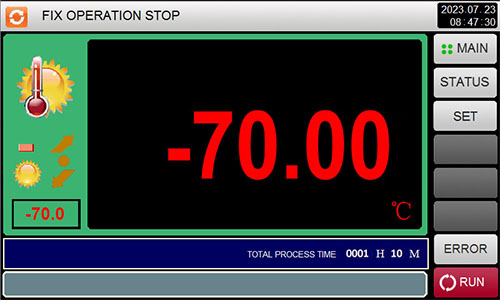

Capable of operating from –70 °C up to +150 °C or higher, the chamber accommodates extreme cold, high-temperature, and thermal shock pre-tests. Multiple low-temperature settings (–20 °C, –40 °C, –70 °C) allow precise matching to test requirements, preventing over-specification and reducing unnecessary procurement costs.

2. Stable Long-Duration Operation

Designed for extended testing, it supports continuous operation for 1000–3000 hours, making it ideal for aging, reliability, and lifespan verification without interruption.

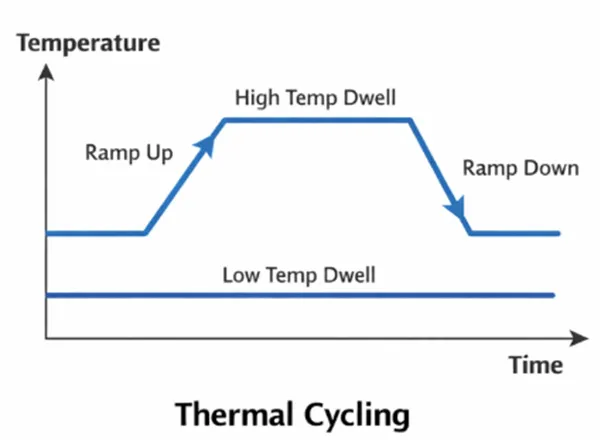

3. Programmable Temperature Ramp & Multi-Stage Profiles

Customizable heating and cooling rates enable different stress levels for each product stage, avoiding over-stressing and unrealistic failures. Multi-stage temperature curves—including gradient ramps, step cycles, and thermal shock simulations—faithfully replicate real-world conditions.

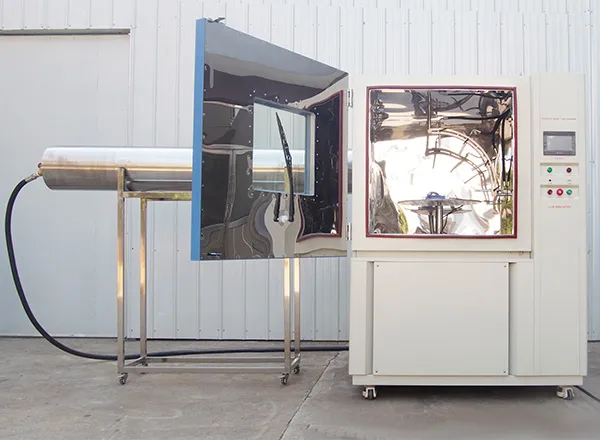

4. Live Testing & Versatile Sample Compatibility

Supports powered (live) testing, allowing products to operate under test conditions for real-time observation of functional stability. Compatible with various sample types, including electronic components, PCBs, complete assemblies, and modules made of metal, plastic, or composite materials.

5. Compliance with International Standards & Certification Support

Meets IEC, ISO, ASTM, MIL-STD, SAE standards, facilitating global product certification such as CE, UL, TÜV, ETL, and ensuring products are ready for market access with recognized testing credentials.

Temperature Chamber Specifications

Model | T-100 | T-225 | T-500 | T-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 1000L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

Cooling system | Mechanical compression refrigeration system |

Refrigerating unit | French TECUMSEH compressor |

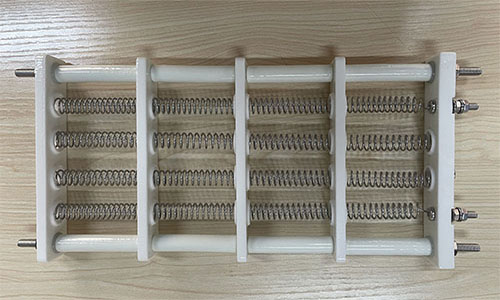

Heating Element | Nichrome heater |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water supply system | Automatic water supply, Water purification system |

Safety Device | Over-temperature protection; Over-current protection; Refrigerant high-pressure protection; Earth leakage protection |

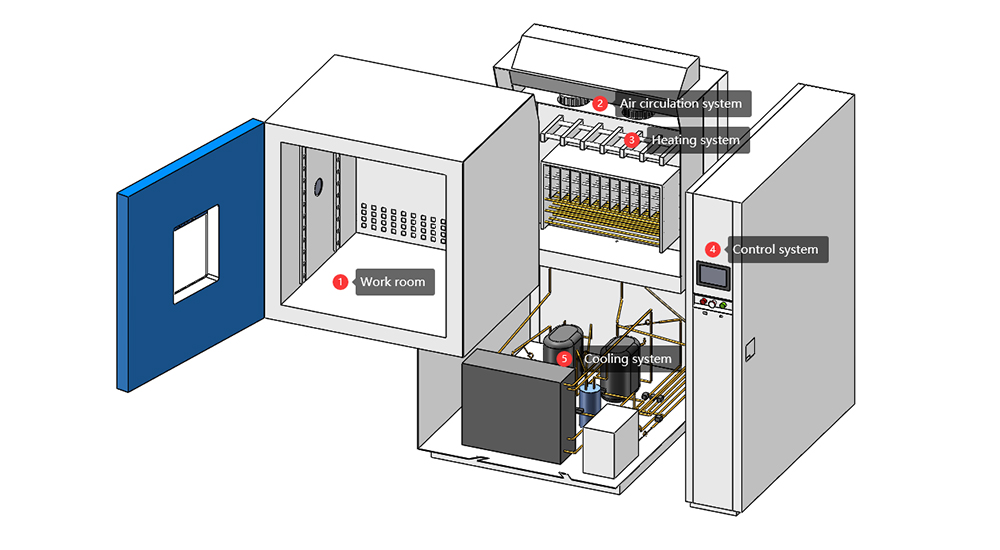

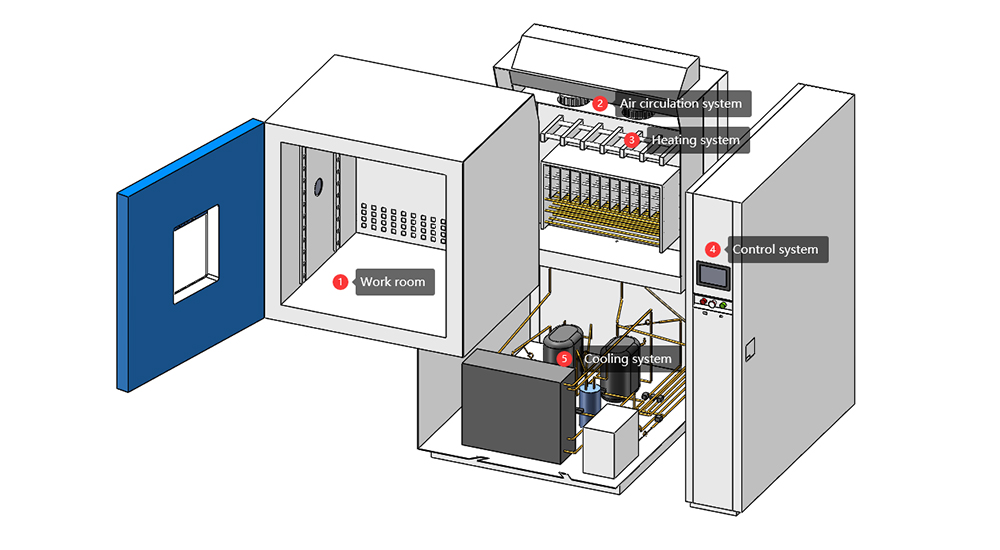

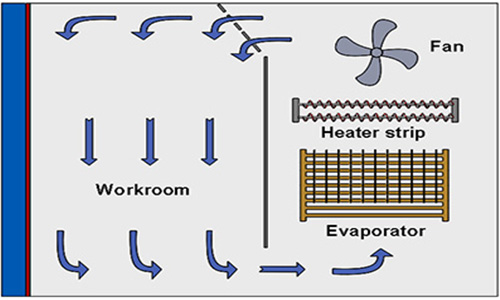

Configuration of Temperature Chamber

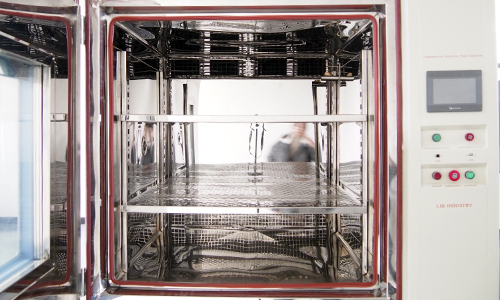

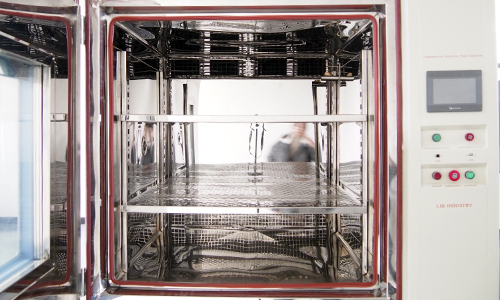

① WorkroomInner chamber made of SUS304 mirror-finished stainless steel for corrosion resistance and high-temperature tolerance. Double-layer perforated shelves, load capacity up to 50 kg, adjustable for different sample sizes. Observation window with built-in LED lighting for real-time monitoring. Optional anti-scratch or chemical-resistant coating for harsh test conditions.

|  |

② Control system

Programmable controller with multi-step temperature profiles. Supports ramp, dwell, and cycle logic. Automatic fault detection with alarms and error codes. USB/Ethernet interface for data export and traceability. Optional integration with remote monitoring or lab management systems.

|  |

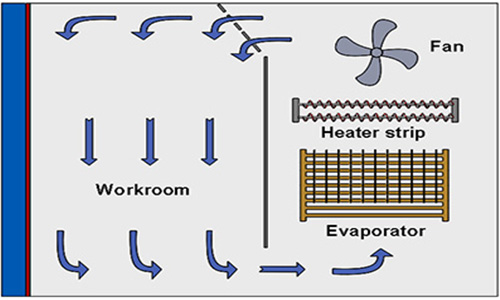

③ Air circulation systemForced air circulation ensures uniform temperature distribution. Multi-directional airflow reduces hot/cold spots. Designed for stable thermal response under full load.

|  |

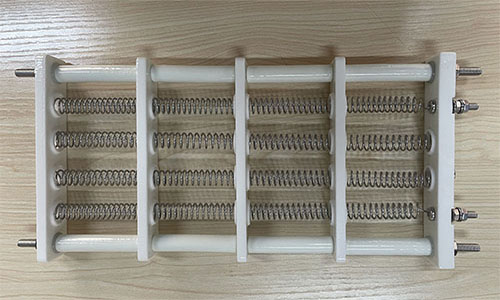

④ Heating system

High-efficiency resistance heating elements. Fast thermal response and stable output. Over-temperature protection ensures sample and equipment safety.

|  |

⑤ Refrigeration system

Mechanical refrigeration with compressor, condenser, evaporator, and throttling device. Optimized for frequent thermal cycling and long-duration operation. Maintains stable low temperatures with minimal deviation. Optional low-noise and eco-friendly refrigerants.

|  |

Customization & Expandability

Size & Volume: Tailored to fit specific samples or lab layouts

Temperature Range & Ramp Rate: Adjustable to match precise test profiles

Observation Windows & Feed-Throughs: Optional for real-time monitoring

Special Sample Fixtures: Custom clamps and holders for diverse materials

Software Functions: Programmable multi-stage profiles, automated sequences, and advanced data logging

Worldwide Support & Fast Response

LIB industry provides a 3-year warranty and lifelong technical guidance. Our English-speaking support team responds within 1–3 hours, 24/7 worldwide. Critical spare parts are stocked internationally for delivery in 7–15 days, with clear instructions for safe shipping, installation, and operation.

Get Started Today: Contact us inquiry@libtestchamber.com for a customized solution, fast quotation, and expert guidance for your temperature chamber.

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia