Cryogenic Chamber Features and Benefits

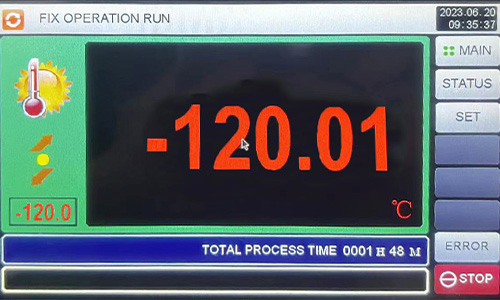

Extreme Low-Temperature Capability

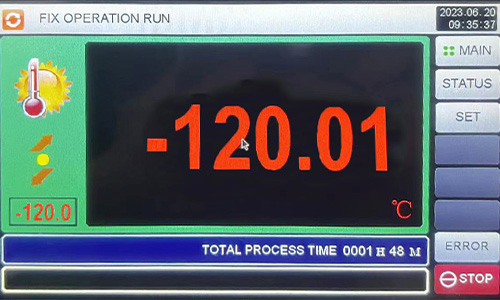

Achieves stable cryogenic conditions down to -120°C, or lower

Continuously and accurately reproduces extreme low-temperature environments

Suitable for aerospace, high-altitude, and polar applications

High Temperature Control Accuracy and Stability

Precision control up to ±0.5°C

Maintains stable temperature during long-duration deep cold operation

Multi-point temperature sampling ensures uniformity and avoids local deviations

Efficient Refrigeration System

High-performance mechanical cascade refrigeration

Fast cooling speeds for reduced test preparation time

No liquid nitrogen required, lowering cost and improving safety

Material and Structural Performance Testing

Evaluates material brittleness, shrinkage, and cracking risk

Reveals defects not observable at conventional temperatures

Provides reliable data for material selection and structural design

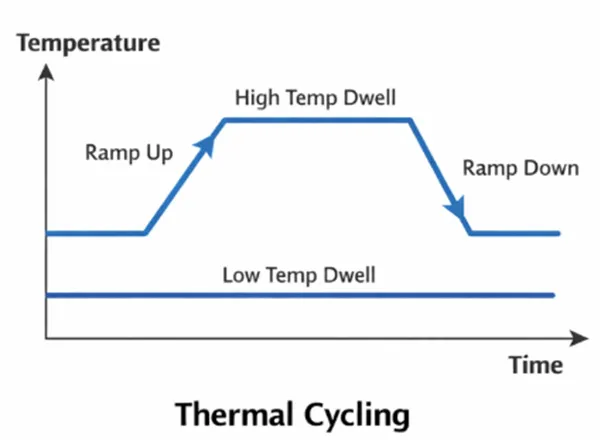

Automated and Intelligent Control

Touchscreen operation with programmable test sequences

Automatic recording and export of test data

Supports remote monitoring for unattended testing

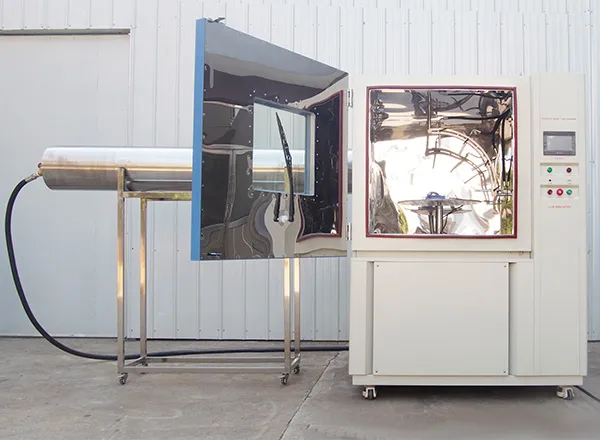

Cryogenic Chamber Specifications

Model | CF-100 | CF-225 | CF-500 | CF-800 | CF-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 800*1000*1000 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1300*1540*2120 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 800L | 1000L |

Temperature Range | -120℃ ~ +150℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

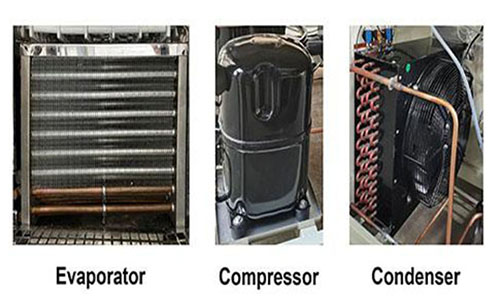

Cooling system | Mechanical compression refrigeration system |

Refrigerating unit | Cascade compressor |

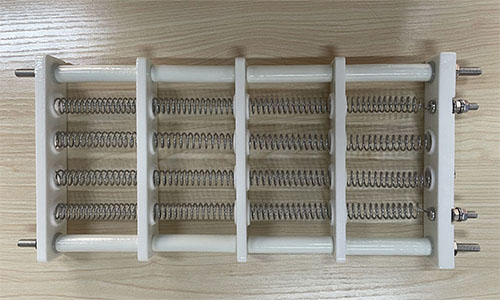

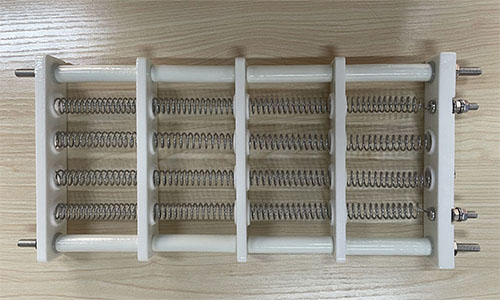

Heating Element | Nichrome heater |

Controller | Programmable color LCD touch screen controller,Ethernet connection |

Safety Device | Over-temperature Protection; Over-current Protection; Refrigerant High-Pressure Protection; Earth leakage Protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Thermal Insulation | Plyurethane foam and insulation cotton |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves |

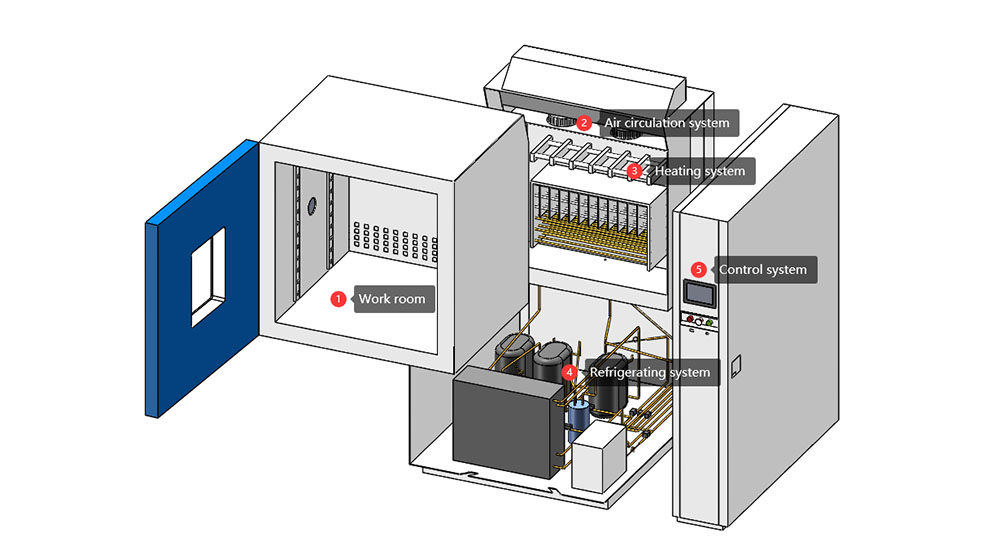

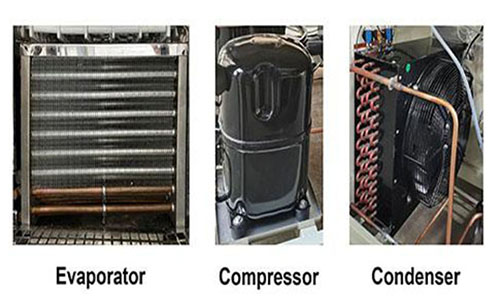

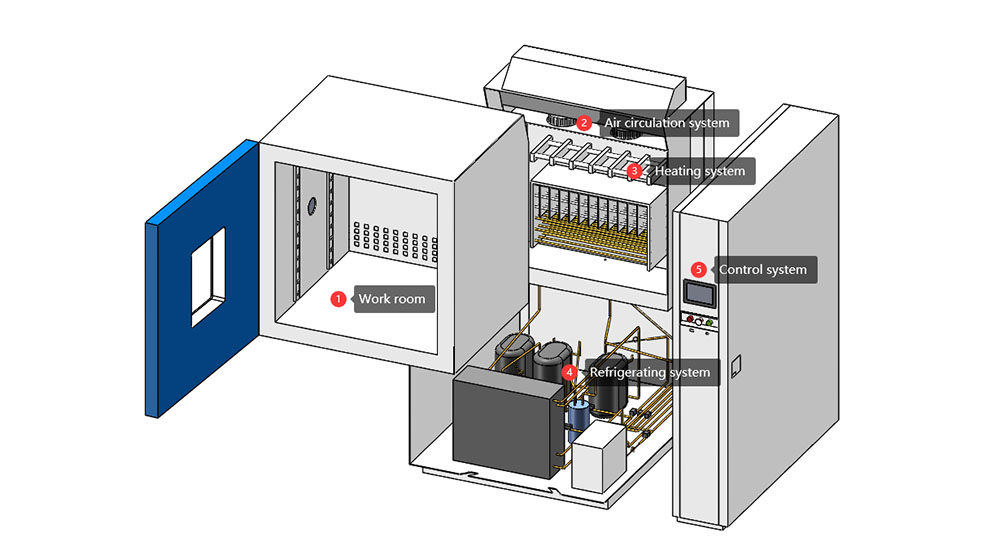

Configuration of Cryogenic Chamber

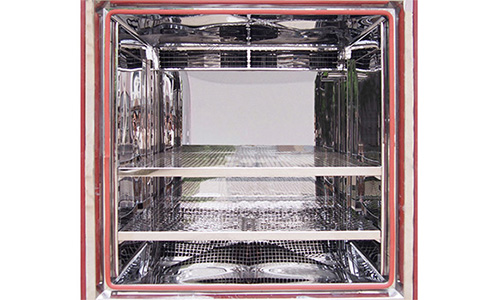

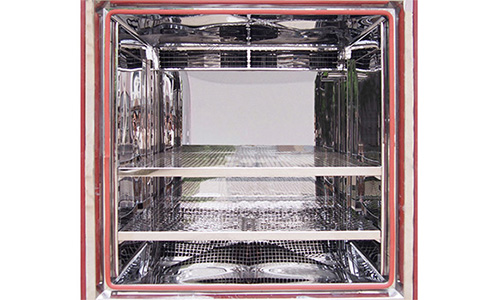

| ①Workroom | SUS304 stainless steel, which offers excellent resistance to both high and ultra-low temperatures and ensures dimensional stability during long-term deep cold testing. The standard configuration includes double adjustable sample holders. Precision sealing strips and well-engineered sealing structures effectively prevent cold air leakage, maintaining stable cryogenic conditions. |  |

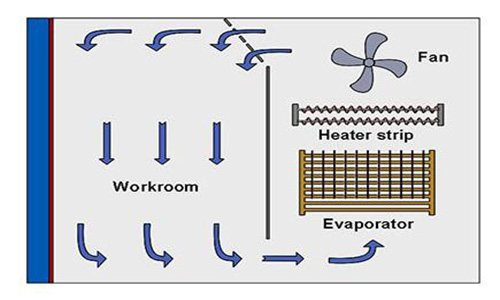

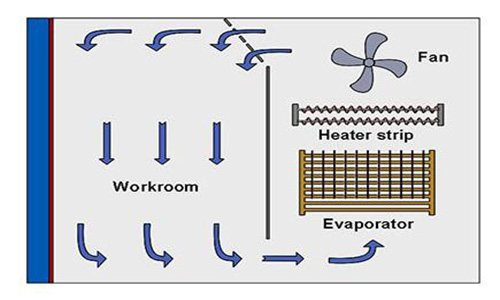

②Air circulation system | Fans circulate air throughout the workroom, ensuring uniform temperature distribution even at -120°C. Multi-point airflow design maintains temperature deviation within ±2°C, which is critical for reproducible cryogenic testing and accurate material or component evaluation. |  |

③Heating system | The chamber uses nickel-chromium alloy heating elements, providing fast and stable heat input when transitioning from cryogenic conditions to elevated temperatures. The system can reliably reach up to +150°C, enabling rapid recovery phases and combined temperature cycling tests. |  |

④Refrigeration system | The chamber uses a cascade mechanical refrigeration system to reach -120°C. Comprising compressors, condensers, capillaries, and evaporators, it ensures continuous, efficient deep-cold operation with reliable temperature stability. |  |

⑤Control system | Both heating and cooling systems are precisely managed by an advanced PID control algorithm, optimized for deep cryogenic environments. Multiple safety protections—including over-temperature protection, compressor overload protection, and system fault alarms.

|  |

FAQ-Cryogenic Chamber

Q1: What is the minimum temperature the cryogenic chamber can reach?

A1: LIB industry cryogenic chambers can reliably achieve -80°C, -100°C, and -120°C, with some high-end models reaching -150°C or lower, depending on the refrigeration system. This ensures stable deep-cold performance for aerospace, automotive, electronics, and materials testing.

Q2: How fast can the chamber cool down?

A2: Cooling rates typically range from 1–3°C per minute and can be adjusted for different samples. LIB industry’s cascade refrigeration system delivers efficient, controlled cooling while maintaining precise temperature stability.

Q3: Are test data traceable?

A3: Yes. The chamber automatically records temperature, and program curves. Data can be exported for analysis or quality audits, giving engineers and managers confidence in reproducible and reliable test results.

Ensure Reliable Cryogenic Testing with LIB Industry

Backed by a 3-year warranty, long-term technical support, and 1–3 hour remote response, we help minimize downtime and ensure consistent test conditions. Standardized spare parts are available globally, typically delivered within 7–15 days, supporting uninterrupted operation for critical aerospace, automotive, electronics, and materials testing programs.

Contact LIB industry at inquiry@libtestchamber.com.

![]()

English

English русский

русский français

français العربية

العربية Deutsch

Deutsch Español

Español 한국어

한국어 italiano

italiano tiếng việt

tiếng việt ไทย

ไทย Indonesia

Indonesia